Dielectric Al/CuO composite film energetic electric ignition bridge and ignition bridge array

A composite film, electric ignition technology, applied in the field of ignition arrays, can solve problems such as low energy conversion rate, and achieve the effects of improving compatibility, improving ignition ability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

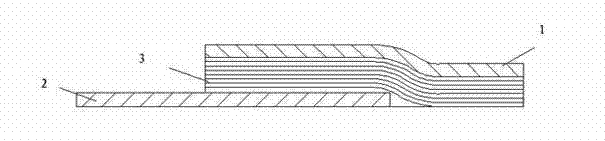

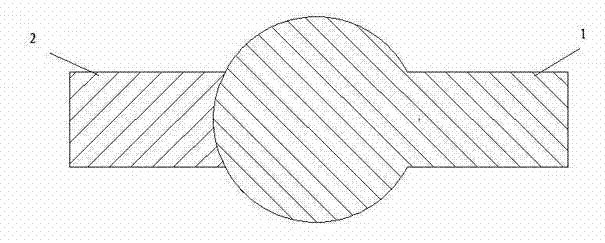

[0026] Dielectric Al / CuO Composite Thin Film Energetic Ignition Bridge Based on Cr Metal Film Heating

[0027] Using the 2μm Cr metal film as the upper and lower electrodes, and the Al / CuO composite film with 6 modulation periods (thickness 7.2μm) as the dielectric layer, the ignition bridge was fabricated by the above microfabrication process. The size of the upper and lower electrode layers of the ignition bridge is: 1000 μm × 1000 μm × 2 μm, and the Al / CuO composite thin film dielectric layer is: 1000 μm × 1000 μm × 7.2 μm. The electrical breakdown of the dielectric layer can be realized by using a 40V DC constant voltage, the obtained ignition delay time is 0.7ms, and the consumed electric energy is 381mJ. The chemical reaction heat released by the Al / CuO composite film is 101.34mJ, so the total heat of reaction is 484.34mJ, and the chemical reaction heat accounts for 21% of the total released energy. Through the ignition temperature test of the ignition bridge, it can be...

Embodiment 2

[0029] Dielectric Al / CuO Composite Thin Film Energetic Ignition Bridge Based on Ti Metal Film Heating

[0030]Using the 2 μm Ti metal film as the upper and lower electrodes, and the Al / CuO composite film with 6 modulation periods (thickness 7.2 μm) as the dielectric layer, the ignition bridge was fabricated by the above-mentioned microfabrication process. The size of the upper and lower electrode layers of the ignition bridge is: 1000 μm × 1000 μm × 2 μm, and the Al / CuO composite thin film dielectric layer is: 1000 μm × 1000 μm × 7.2 μm. The electrical breakdown of the dielectric layer can be achieved by using a 40V DC constant voltage, the obtained ignition delay time is 1.2ms, and the consumed electric energy is 432mJ. The chemical reaction heat released by the Al / CuO composite film is 101.34mJ, so the total heat of reaction is 533.34mJ, and the chemical reaction heat accounts for 19% of the total released energy. Through the ignition temperature test of the ignition bridge...

Embodiment 3

[0032] Dielectric Al / CuO Composite Thin Film Energetic Ignition Bridge Based on Cu Metal Film Heating

[0033] Using 2 μm Cu metal film as the upper and lower electrodes, Al / CuO composite film with 6 modulation periods (thickness 7.2 μm) as the dielectric layer, the ignition bridge was fabricated by the above microfabrication process. The size of the upper and lower electrode layers of the ignition bridge is: 1000 μm × 1000 μm × 2 μm, and the Al / CuO composite thin film dielectric layer is: 1000 μm × 1000 μm × 7.2 μm. The electrical breakdown of the dielectric layer can be realized by using a 40V DC constant voltage, the obtained ignition delay time is 0.5ms, and the consumed electric energy is 212mJ. The chemical reaction heat released by the Al / CuO composite film is 101.34mJ, so the total heat of reaction is 313.34mJ, and the chemical reaction heat accounts for 32% of the total released energy. Through the ignition temperature test of the ignition bridge, it can be seen that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com