A kind of method for manufacturing polyamide reverse osmosis composite membrane

A technology of reverse osmosis composite membrane and polyamide, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as reducing retention rate or water flux, increasing pretreatment cost, and reducing service life. Achieve the effects of increasing the interface bonding strength, improving chemical resistance stability, and increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

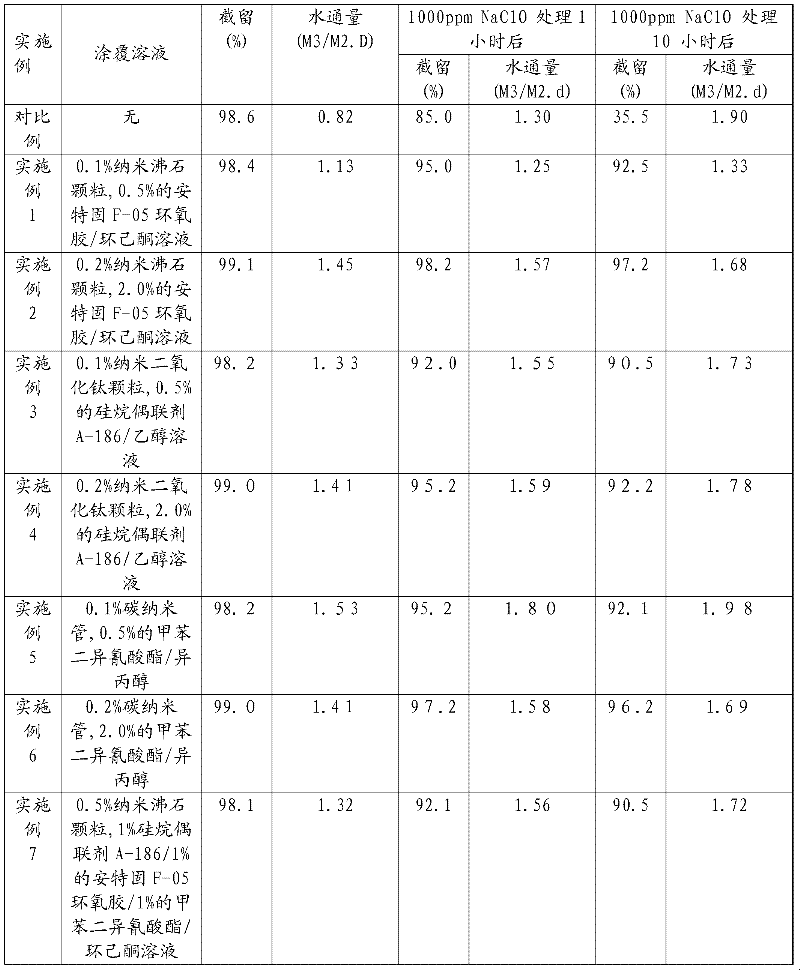

[0023] Example 1, before the supporting base film is immersed in the amine solution, the cyclohexanone solution containing 0.1% nanometer zeolite particles and 0.5% Anteco F-05 epoxy glue is sprayed on the surface of the polysulfone base film for 20 seconds by spraying, After standing vertically for 15 minutes, immerse in 2.0% m-phenylenediamine aqueous solution for 2 minutes, press the surface of the film with a rubber roller until it is semi-dry, then immerse in 0.2% trimesoyl chloride n-hexane solution for 20 seconds; take it out and put it in 110 ℃ oven treatment for 10 minutes, and then thoroughly washed with alkali solution, acid solution, alcohol solution and pure water to test the membrane performance. The test conditions are the same as those of the comparative example, and the results are listed in Table 1. After soaking in 1000ppm NaCl0 aqueous solution for 10 hours, the retention rate of NaCl is still as high as 92.5%. Water flux up to 1.33M 3 / M 2 .d.

Embodiment 2

[0024] Example 2, before the base film is immersed in the amine solution, spray the cyclohexanone solution containing 0.2% nanometer zeolite particles and 2.0% Antesolid F-05 epoxy glue to the surface of the polysulfone base film for 20 seconds, vertically After standing for 15 minutes, immerse in 2.0% m-phenylenediamine aqueous solution for 2 minutes; press the surface of the film with a rubber roller until it is semi-dry, then immerse in 0.2% trimesoyl chloride in n-hexane solution for 20 seconds; take it out and put it in 110°C The oven was treated for 10 minutes, and then thoroughly washed with alkali solution, acid solution, alcohol solution and pure water to test the membrane performance. The test conditions are the same as those of the comparative example, and the results are listed in Table 1. After soaking in 1000ppm NaCl0 aqueous solution for 10 hours, the retention rate of NaCl is still as high as 97.2%. Water flux up to 1.68M 3 / M 2 .d.

Embodiment 3

[0025] Example 3, before the support base film is immersed in the amine solution, spray the ethanol solution containing 0.1% nano-titanium dioxide particles and 0.5% silane coupling agent A-186 to the surface of the polysulfone base film for 20 seconds, and place it vertically for 15 minutes Finally, immerse in 2.0% m-phenylenediamine aqueous solution for 2 minutes, press the surface of the film with a rubber roller until it is semi-dry, then immerse in 0.2% trimesoyl chloride in n-hexane solution for 20 seconds; take it out and put it in an oven at 110°C for treatment After 10 minutes, the membrane performance was tested after being thoroughly washed with alkaline solution, acid solution, alcohol solution and pure water. The test conditions are the same as those of the comparative example, and the results are listed in Table 1. After soaking in 1000ppm NaCl0 aqueous solution for 10 hours, the retention rate of NaCl is still as high as 90.5%. Water flux up to 1.73M 3 / M 2 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com