Preparation method for metallized plastic wind instrument

A technology for plastic pipes and wind instruments, which is applied to musical instruments, wind instruments, instruments, etc. It can solve the problems of large pitch changes, difficulty in mass production, and pollution resistance, and achieve the effects of thick timbre, low cost, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

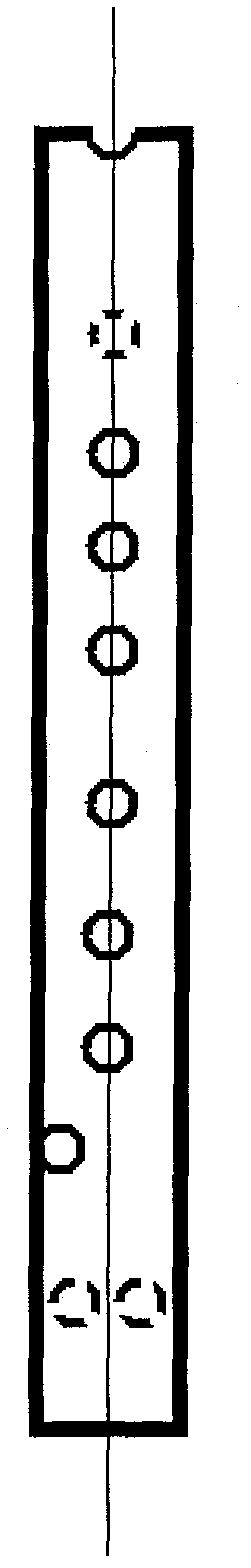

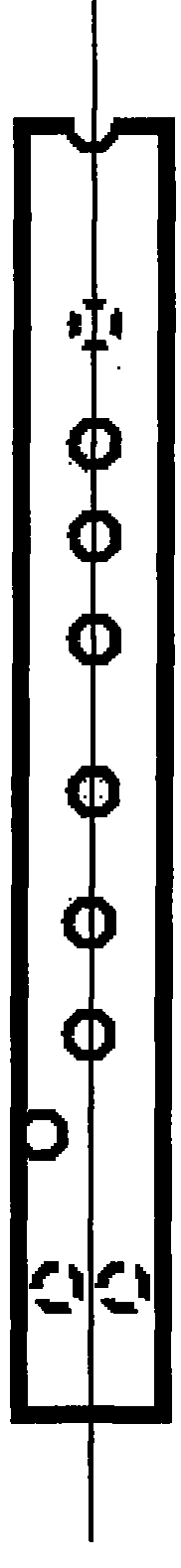

[0017] 1. Take a PE plastic tube with a total length of 70 cm. The outer diameter of the plastic tube is 2.65 cm and the inner diameter is 2.10 cm. A mouthpiece, eight sound holes and two sound outlet holes are opened on the plastic tube; the mouthpiece is opened on the The top edge of the plastic tube, with the side of the mouthpiece as the front, and the center of the mouthpiece down as the front central axis, the position of the corresponding front central axis has a reverse central axis on the back of the plastic tube; seven sound-pressing holes are opened on the front of the plastic tube, of which six One hole is opened along the central axis of the front. The distance from the bottom of the six sound holes to the bottom of the plastic tube is 28.8cm, 30.8cm, 33.8cm, 37.8cm, 40.0cm, and 42.2cm. The center of the hole is on the central axis of the front. Open the seventh sound hole on the left side of the axis, the distance between the lower end of the sound hole and the bo...

Embodiment 2

[0023] 1. Take a PVC plastic tube with a total length of 70 cm. The outer diameter of the plastic tube is 2.65 cm and the inner diameter is 2.10 cm. A mouthpiece, eight sound holes and two sound outlet holes are opened on the plastic tube; the mouthpiece is opened on the The top edge of the plastic tube, with the side of the mouthpiece as the front, and the center of the mouthpiece down as the front central axis, the position of the corresponding front central axis has a reverse central axis on the back of the plastic tube; seven sound-pressing holes are opened on the front of the plastic tube, of which six One hole is opened along the central axis of the front. The distance from the bottom of the six sound holes to the bottom of the plastic tube is 28.8cm, 30.8cm, 33.8cm, 37.8cm, 40.0cm, and 42.2cm. The center of the hole is on the central axis of the front. Open the seventh sound hole on the left side of the axis, the distance between the lower end of the sound hole and the b...

Embodiment 3

[0029]1. Take a PP material plastic tube with a total length of 70 cm. The outer diameter of the plastic tube is 2.65 cm and the inner diameter is 2.10 cm. A mouthpiece, eight sound holes and two sound outlet holes are opened on the plastic tube; the mouthpiece is opened on the The top edge of the plastic tube, with the side of the mouthpiece as the front, and the center of the mouthpiece down as the front central axis, the position of the corresponding front central axis has a reverse central axis on the back of the plastic tube; seven sound-pressing holes are opened on the front of the plastic tube, of which six One hole is opened along the central axis of the front. The distance from the bottom of the six sound holes to the bottom of the plastic tube is 28.8cm, 30.8cm, 33.8cm, 37.8cm, 40.0cm, and 42.2cm. The center of the hole is on the central axis of the front. Open the seventh sound hole on the left side of the axis, the distance between the lower end of the sound hole an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com