Co-production preparation method of 2-chloro-3,3,3-trifluoropropene and 2,3-dichloro-1,1-difluoro propylene

A technology of trifluoropropene and difluoropropene, which is applied in the field of chemical preparation, can solve problems such as inability to co-produce, and achieve the effect of reducing overfluorination and increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

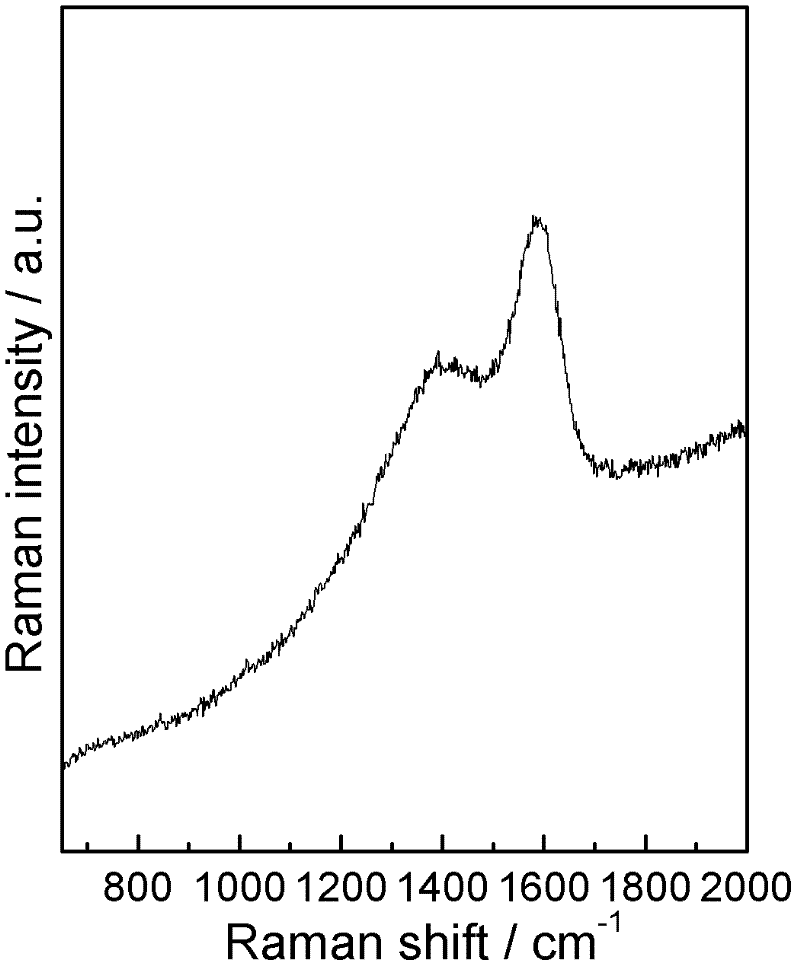

Image

Examples

Embodiment 1

[0026]According to the molar ratio of Al and Cr 1:1, weigh a certain amount of Al respectively 2 o 3 and Cr(NO 3 ) 3 9H 2 O, add water to dissolve Cr(NO 3 ) 3 9H 2 O, then add Al 2 o 3 Stir well, then use (NH 4 ) 2 CO 3 Adjust the pH of the solution to 7-8 to convert the dissolved chromium ions into hydroxide precipitates, then centrifuge, filter with suction, and dry the precipitate at 120°C overnight after suction filtration, and dry the dried material at 500°C, N 2 Calcined under atmosphere for 4h to get Cr 2 o 3 -Al 2 o 3 Catalyst, after tablet molding, is loaded into the reactor.

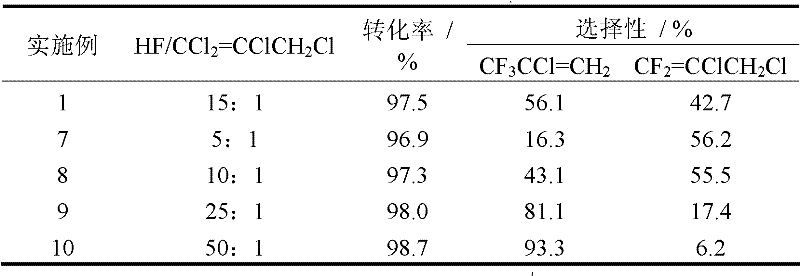

[0027] The inner diameter is 10mm nickel alloy reactor, add 3ml of the above Cr 2 o 3 -Al 2 o 3 Catalyst, remove water under nitrogen atmosphere, then use hydrogen fluoride gas to fluorinate, then use N 2 Diluted 1,1,2,3-tetrachloropropene mixture (5:1) at a space velocity of 500h -1 Pass it into the reactor, inert the catalyst at 400°C for 4 hours, pass the mixed gas of...

Embodiment 2

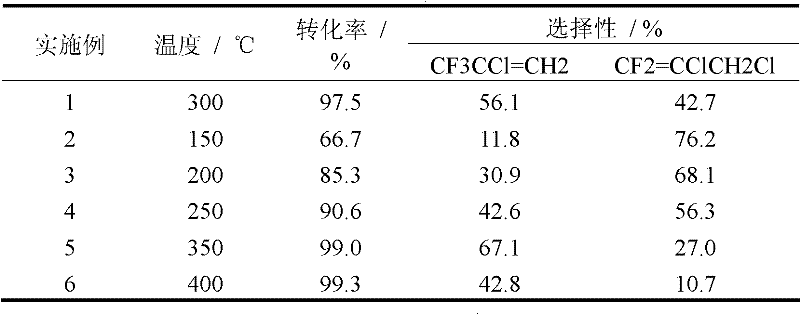

[0030] The same operation as in Example 1, except that the reaction temperature of hydrogen fluoride and 1,1,2,3-tetrachloropropene was changed to 150° C., and the reaction results are shown in Table 1.

Embodiment 3

[0032] The same operation as in Example 1, except that the reaction temperature of hydrogen fluoride and 1,1,2,3-tetrachloropropene was changed to 200° C., and the reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com