Preparation method for micrometer barium-doped zinc oxide

A technology of zinc oxide and barium chloride, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of cumbersome process, poor repeatability, expensive equipment, etc., and achieve the effect of simple method, low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 0.0439g of zinc acetate dihydrate and 0.5678g of barium chloride dihydrate into 75g of distilled water, stir at room temperature for 30 minutes, add 0.12g of polyvinylpyrrolidone K-30, stir at room temperature for 30 minutes, add 3g of 5mol / L NaOH aqueous solution, poly The mass ratio of vinylpyrrolidone K-30 to zinc acetate dihydrate, barium chloride dihydrate, 5mol / L NaOH solution, and distilled water is 1:0.3658:4.732:25:625, stir at room temperature, and continue stirring after the solution becomes white turbid For 5 minutes, pour the white turbid liquid into a hydrothermal reaction kettle lined with polytetrafluoroethylene, seal the hydrothermal reaction kettle, put the hydrothermal reaction kettle in an oven at a temperature of 180°C for 24 hours, and centrifuge. The precipitate was alternately washed three times with distilled water and absolute ethanol, and vacuum-dried at 60°C for 24 hours to prepare a micron barium-doped zinc oxide material.

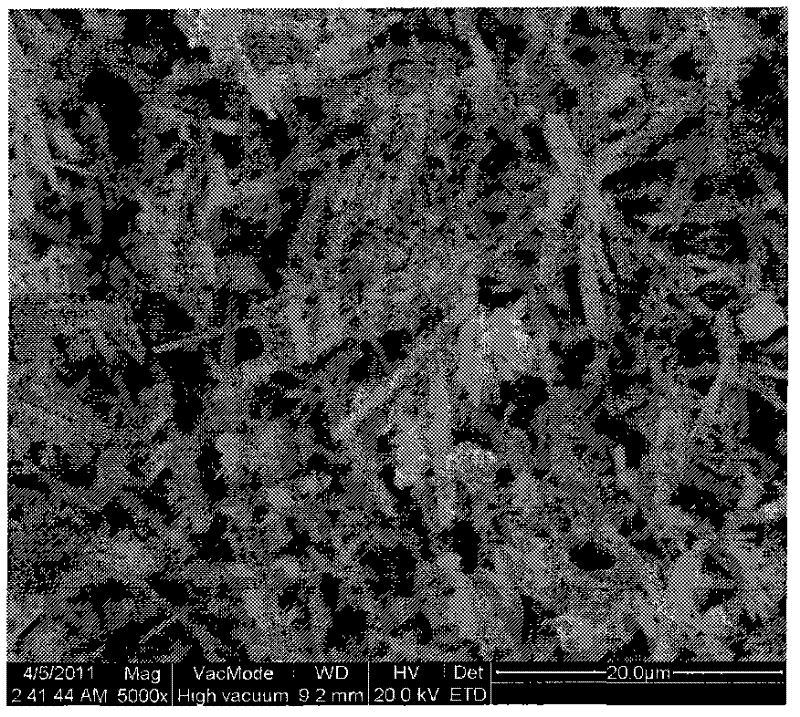

[0026] The r...

Embodiment 2

[0028] Add 0.0439g of zinc acetate dihydrate and 0.0122g of barium chloride dihydrate into 75g of distilled water, stir at room temperature for 30 minutes, add 0.12g of polyvinylpyrrolidone K-30, stir at room temperature for 30 minutes, add 3g of 5mol / L NaOH aqueous solution, poly The mass ratio of vinylpyrrolidone K-30 to zinc acetate dihydrate, barium chloride dihydrate, 5mol / L NaOH solution, and distilled water is 1: 0.3658: 0.1017: 25: 625, and the other steps are the same as in Example 1, and prepared into micron Barium doped zinc oxide material.

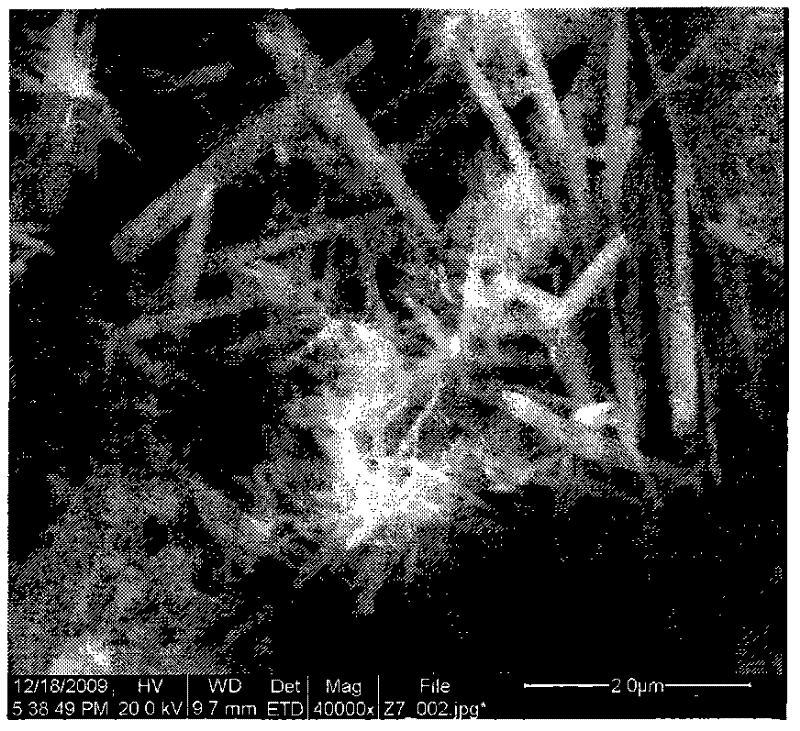

[0029] The resulting product is characterized by a Quanta 200 environmental scanning electron microscope, and the results are shown in figure 2 . Depend on figure 2 It can be seen that the obtained product is barium-doped zinc oxide in micron rod shape, the length of the rod is 0.5-3 μm, and the diameter is 0.2-0.5 μm.

Embodiment 3

[0031] Add 0.0439g of zinc acetate dihydrate and 2.443g of barium chloride dihydrate into 75g of distilled water, stir at room temperature for 30 minutes, add 0.12g of polyvinylpyrrolidone K-30, stir at room temperature for 30 minutes, add 3g of 5mol / L NaOH aqueous solution, poly The mass ratio of vinylpyrrolidone K-30 to zinc acetate dihydrate, barium chloride dihydrate, 5mol / L NaOH solution, and distilled water is 1: 0.3658: 20.36: 25: 625, and the other steps are the same as in Example 1 to prepare micron Barium doped zinc oxide material.

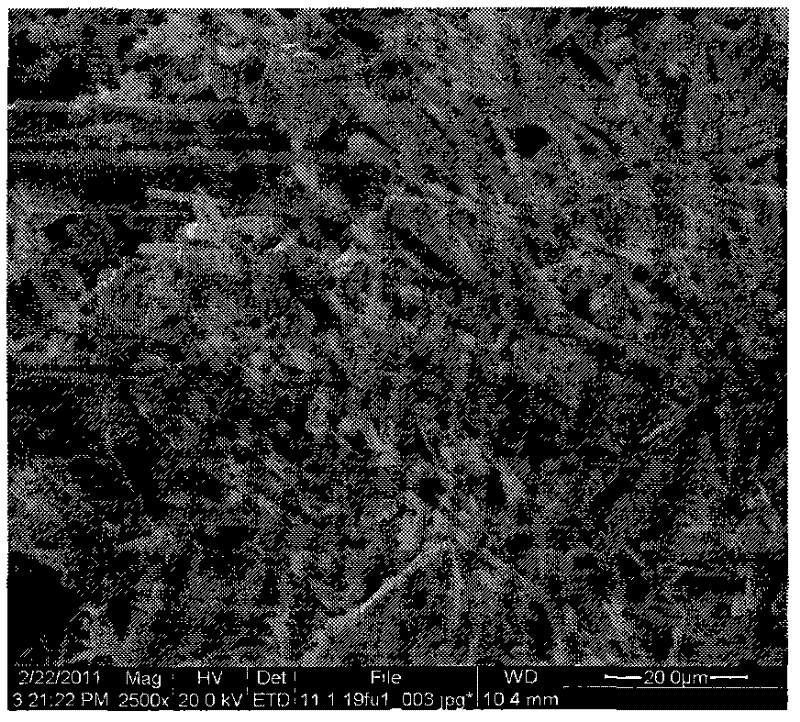

[0032] The resulting product is characterized by a Quanta 200 environmental scanning electron microscope, and the results are shown in image 3 . Depend on image 3 It can be seen that the obtained product is barium-doped zinc oxide in micron rod shape, the length of the rod is 20-50 μm, and the diameter is 5-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com