Device for preparing ultrahard abrasive particle layer by adopting electric spark deposition method

A technology of electric spark deposition and superhard abrasive grains, which is applied in the direction of grinding devices, manufacturing tools, metal processing equipment, etc., can solve the problems that the electric spark deposition of the superhard abrasive grain layer on the surface of the metal matrix grinding wheel cannot be realized, and achieve the realization of Green recycling and reuse to achieve the effect of remanufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

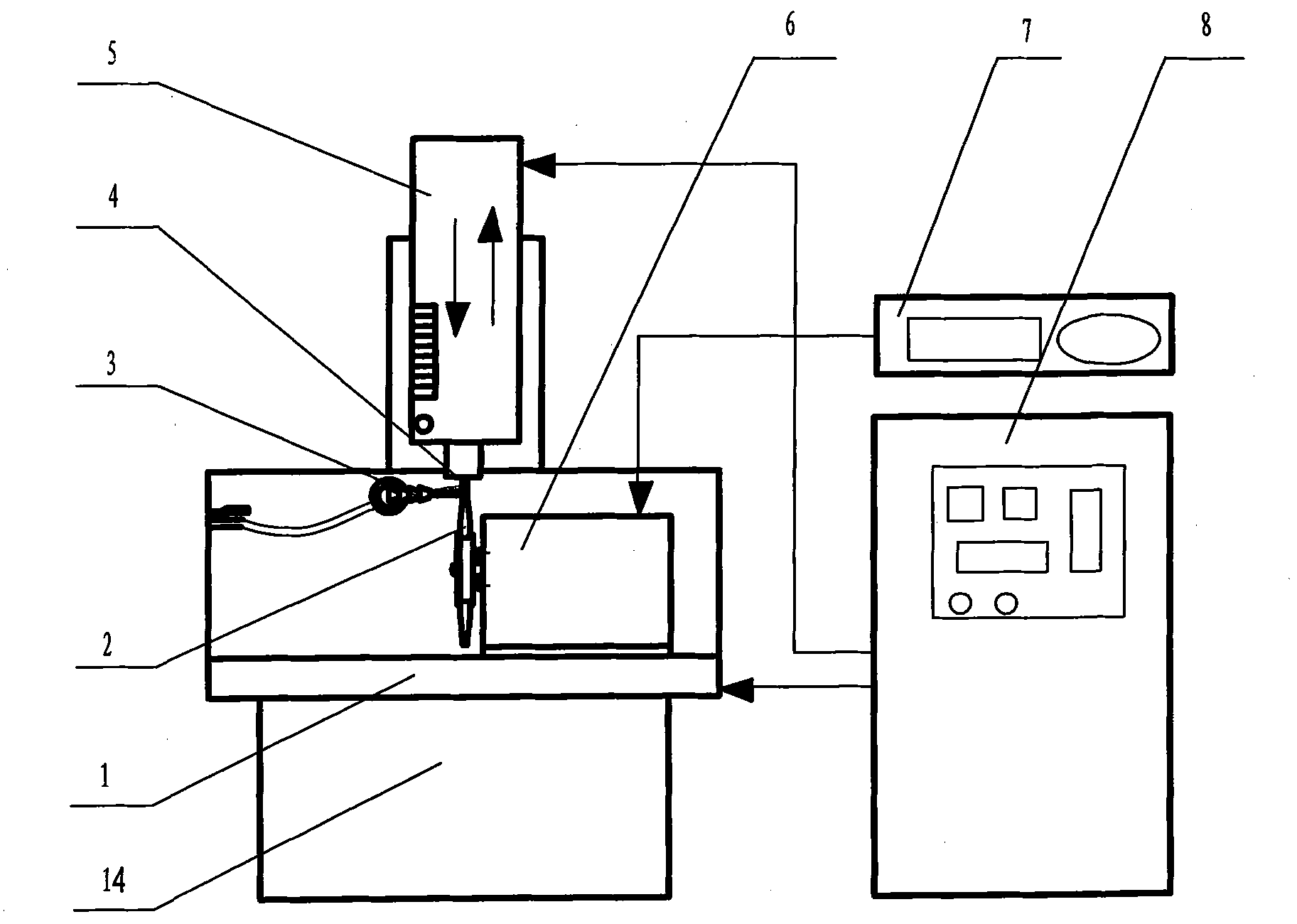

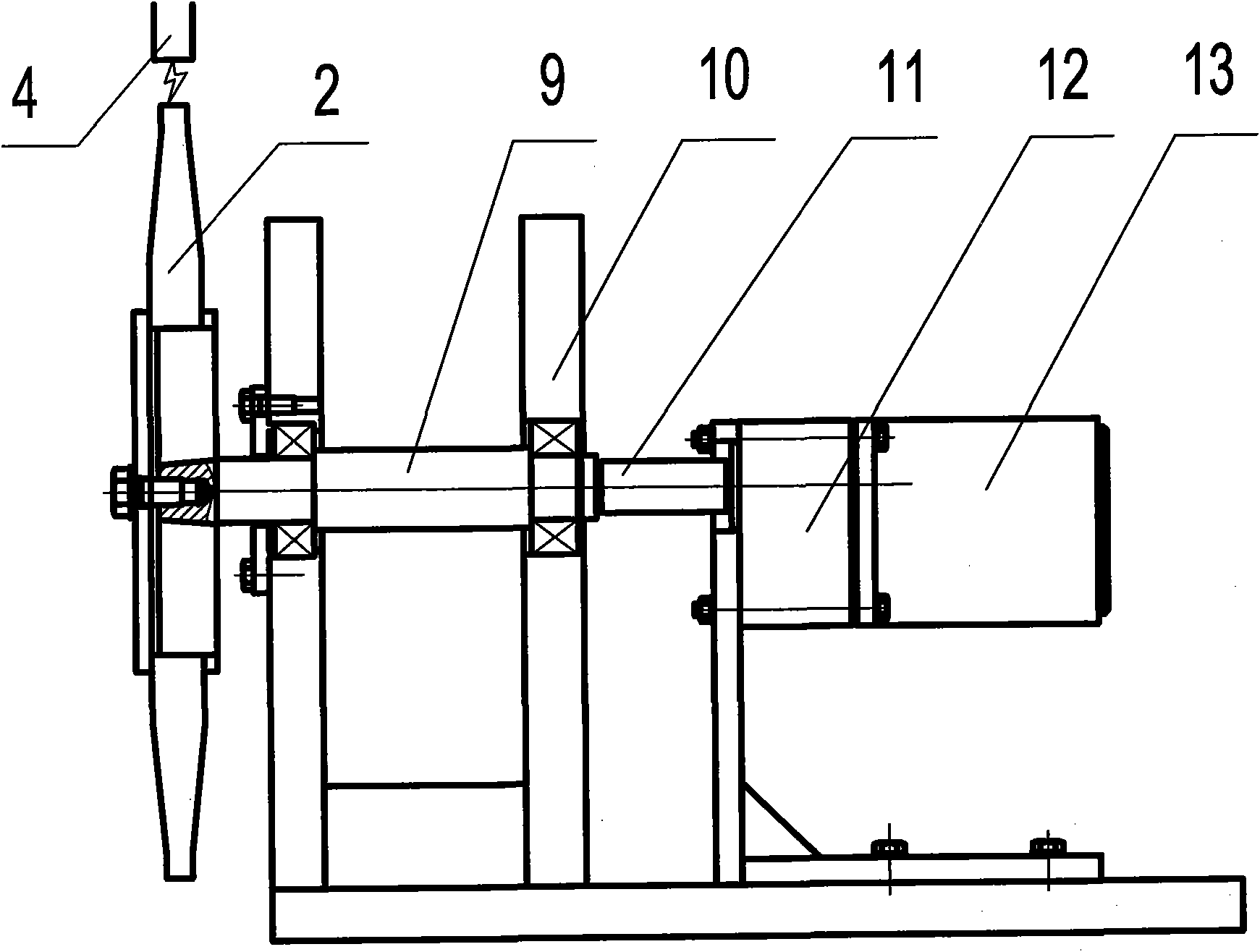

[0024] A device for preparing a superhard abrasive grain layer by electrospark deposition method, see figure 1 and figure 2 , comprising a workbench 1 mounted on the device frame 14, a grinding wheel metal base 2 mounted on the workbench 1, a grinding wheel base driving mechanism 6 that can drive the rotation of the grinding wheel metal base 2 on the workbench 1, the grinding wheel metal A compressed powder electrode 4 is provided on one side of the base body (2). The compressed powder in the compressed powder electrode 4 is formed by pressing and sintering at least one of abrasive grains and metal powder. The compressed powder electrode 4 is installed on a servo mechanism 5 that can move up and down reciprocating linearly, and the other side of the metal base 2 of the grinding wheel is provided with a working fluid that can spray the working fluid on the discharge area between the metal base 2 of the grinding wheel and the compressed powder electrode 4 Nozzle 3, one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com