Spare part micro-arc pulse plasma rapid additive manufacturing device and method

A pulse plasma and additive manufacturing technology, which is applied in the direction of additive manufacturing, additive processing, metal material coating technology, etc., can solve the problems of high manufacturing cost, poor precision of cladding and forming components, and difficult control, etc., and achieves convenient operation , Improving the maintenance support ability and the effect of low environmental demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

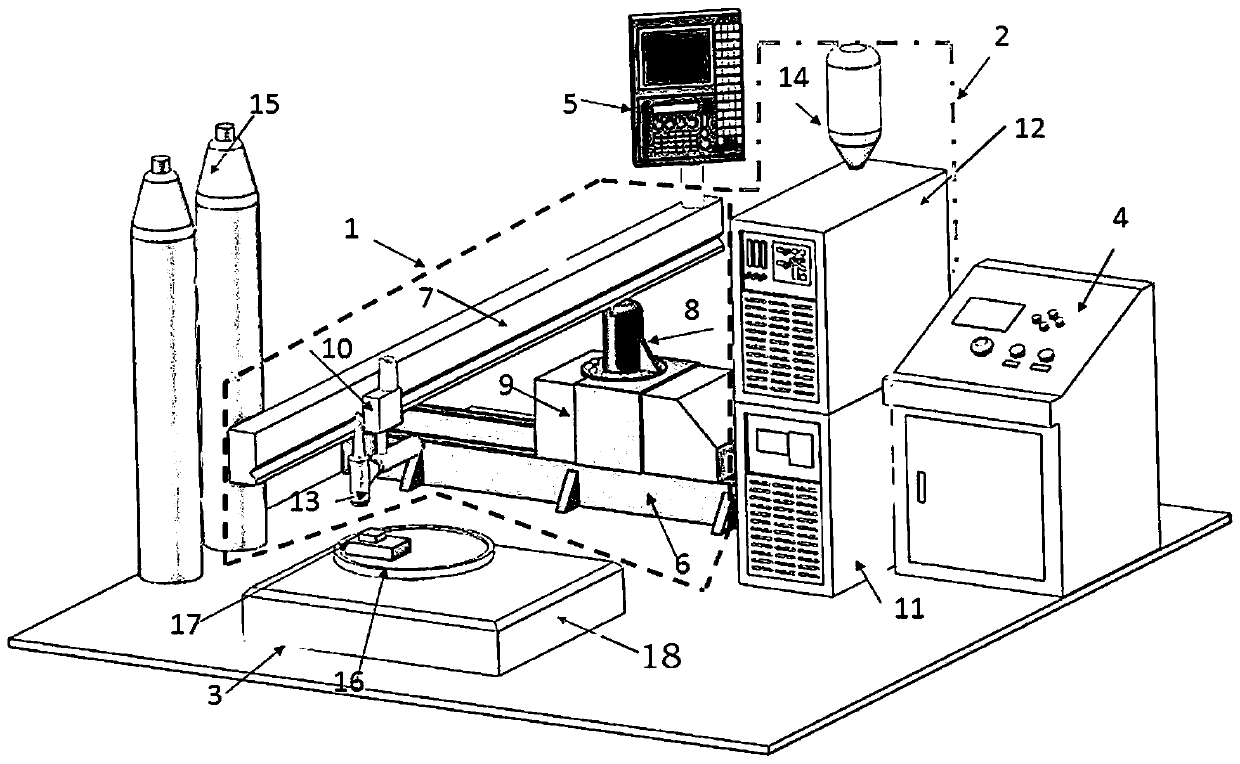

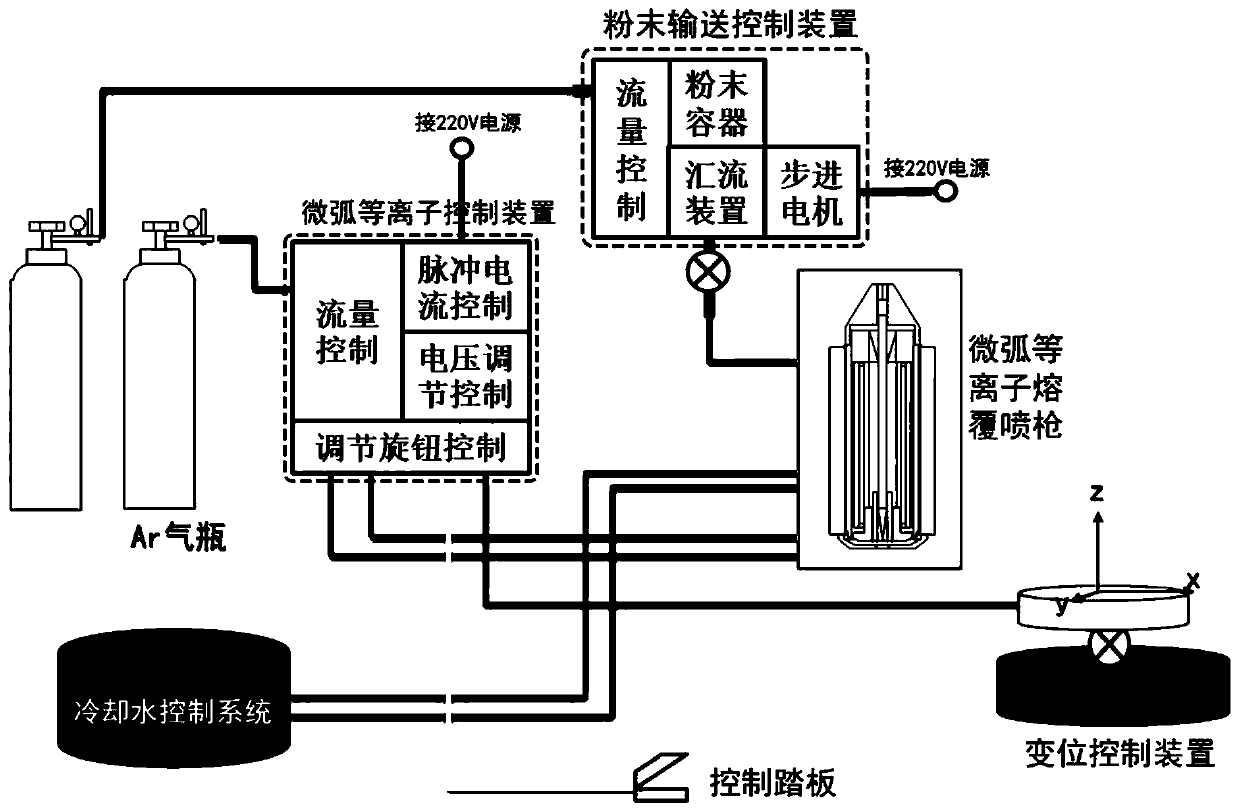

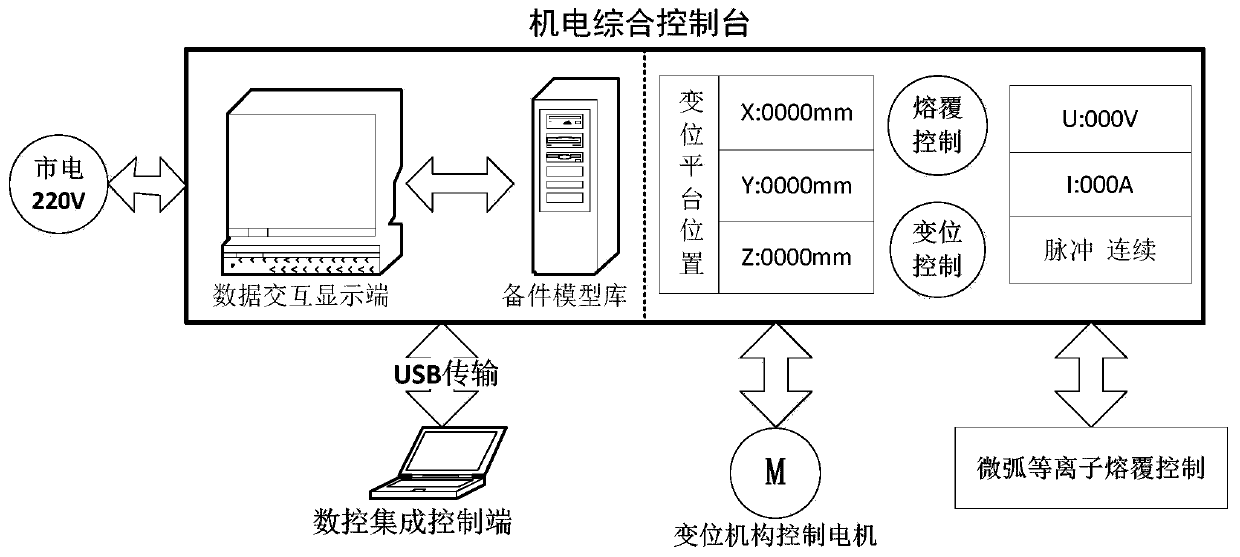

[0033] see figure 1 The spare parts micro-arc pulse plasma rapid additive manufacturing device of the present invention is composed of a spray gun trajectory control mechanism 1, a pulse micro-arc plasma cladding platform 2, a displacement mechanism 3, an electromechanical integrated console 4, and a welding torch path planning numerical control display platform 5, etc. .

[0034] see figure 1 , the spray gun track control mechanism 1 includes a base support frame 6, a slide rail numerically controlled scanning assembly 7, a lift control motor 8, a translation control motor 9 and a welding torch holder 10 installed on the base support frame 6, through which the slide rail numerically controlled scanning The assembly 7 controls the lifting control motor 8 and the translation control motor 9 to work, so as to realize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com