Thick-wall chromium-molybdenum steel pipeline submerged arc welding technology

A welding process and wall chrome molybdenum steel technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as affecting the construction period of the project, failing to meet the needs of the project, etc., and achieve good welding seam forming quality and welding speed. , The effect of high welding production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

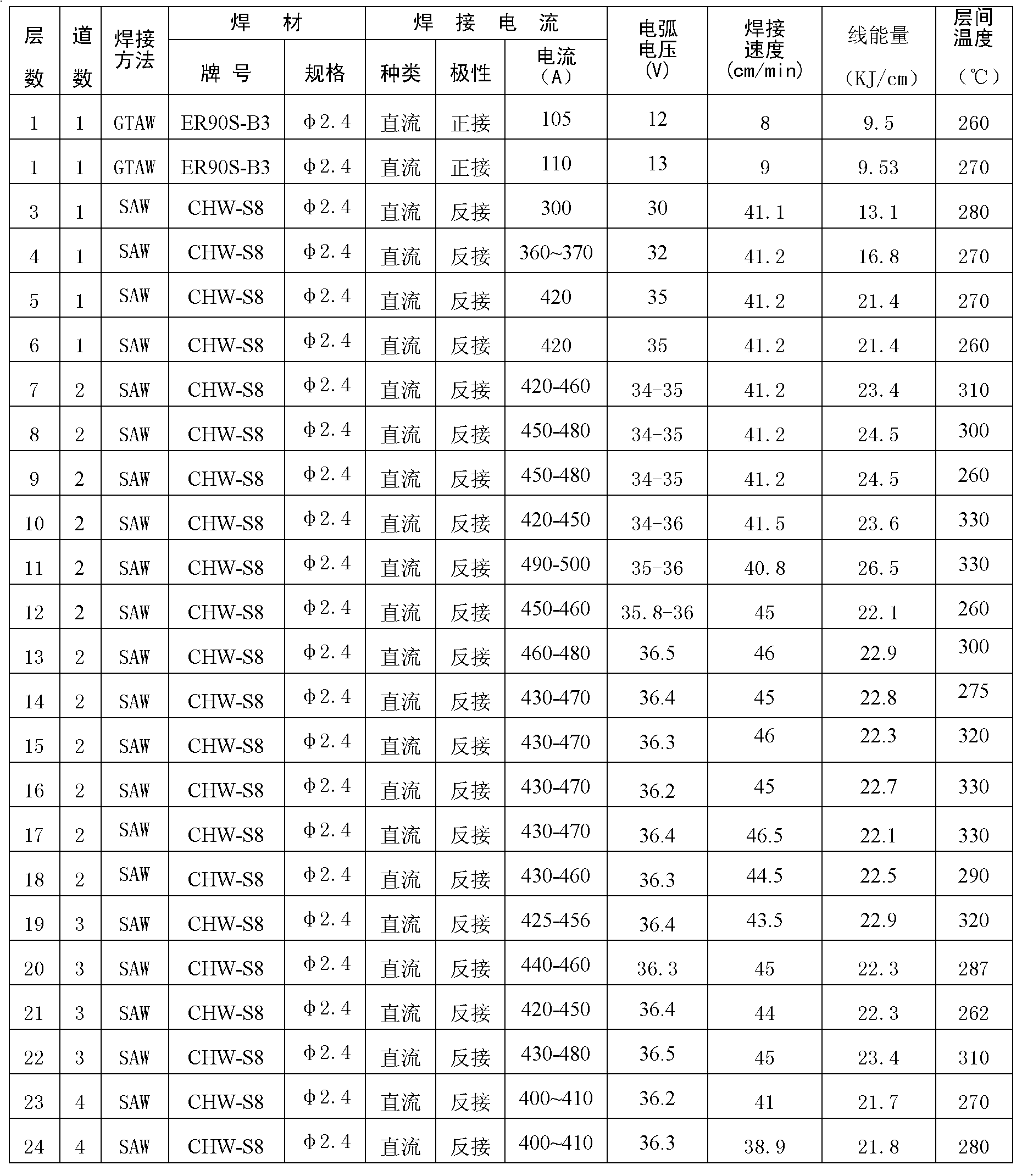

[0023] φ457.2×55.56mm chrome-molybdenum steel P22 pipeline submerged arc welding welding process:

[0024] 1. Bevel processing

[0025] The pipe lathe is used to complete the cutting and beveling of the pipe at one time. Using mechanical processing groove, groove processing quality is good, the utilization rate of machinery is high, and the cutting efficiency is high.

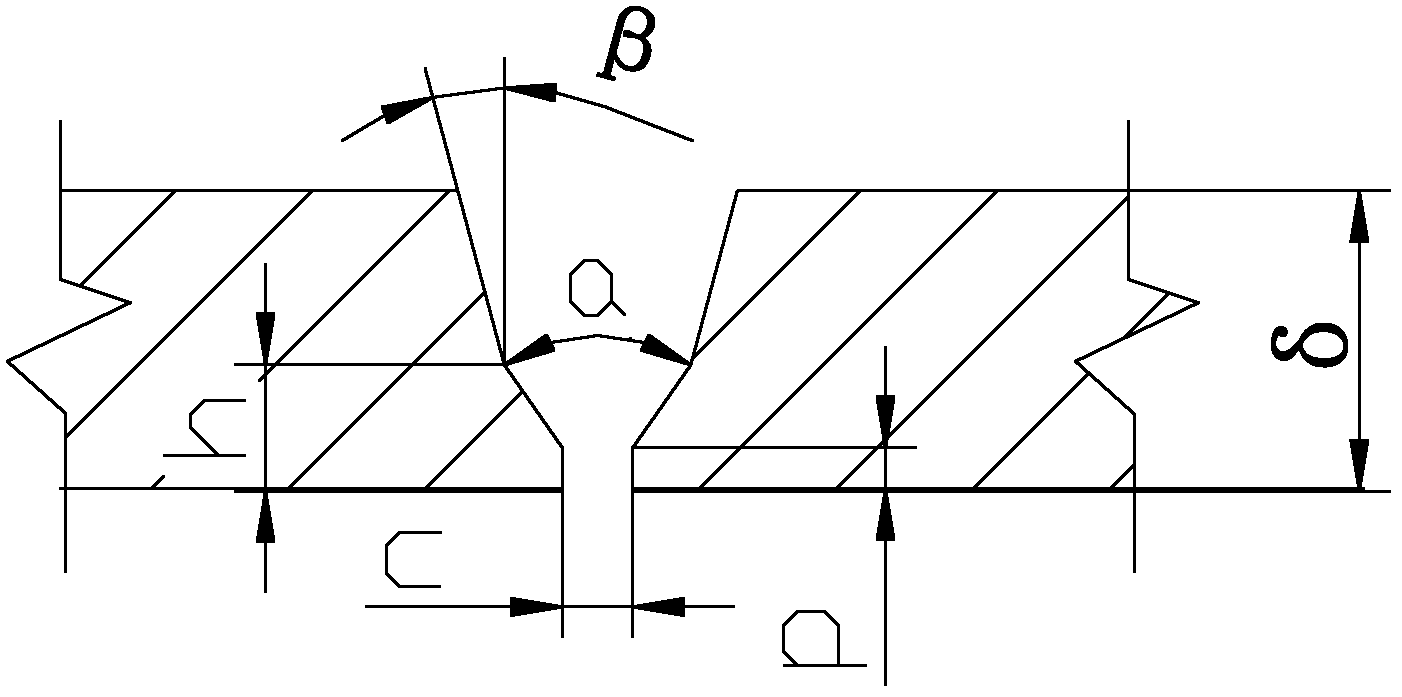

[0026] The bevel is in the form of a double V, see figure 2 , the groove angle of the lower V-shaped groove is α=65°, the groove surface angle of the upper V-shaped groove is β=10°, the thickness of the blunt edge is P=1.5mm, and the distance between the top surface of the lower V-shaped groove and the bottom surface of the base metal is Height h=19mm. The groove should be checked by 100% coloring, and it is qualified if there is no crack.

[0027] 2. Clean up the pair

[0028] Before assembling, use angle grinder, stick grinder or steel file to clean the rust and oil on the groove surface and edge area u...

Embodiment 2

[0044] The welding process of submerged arc welding of φ219×28.58mm chrome-molybdenum steel P22 pipeline is the same as that of Example 1, except that:

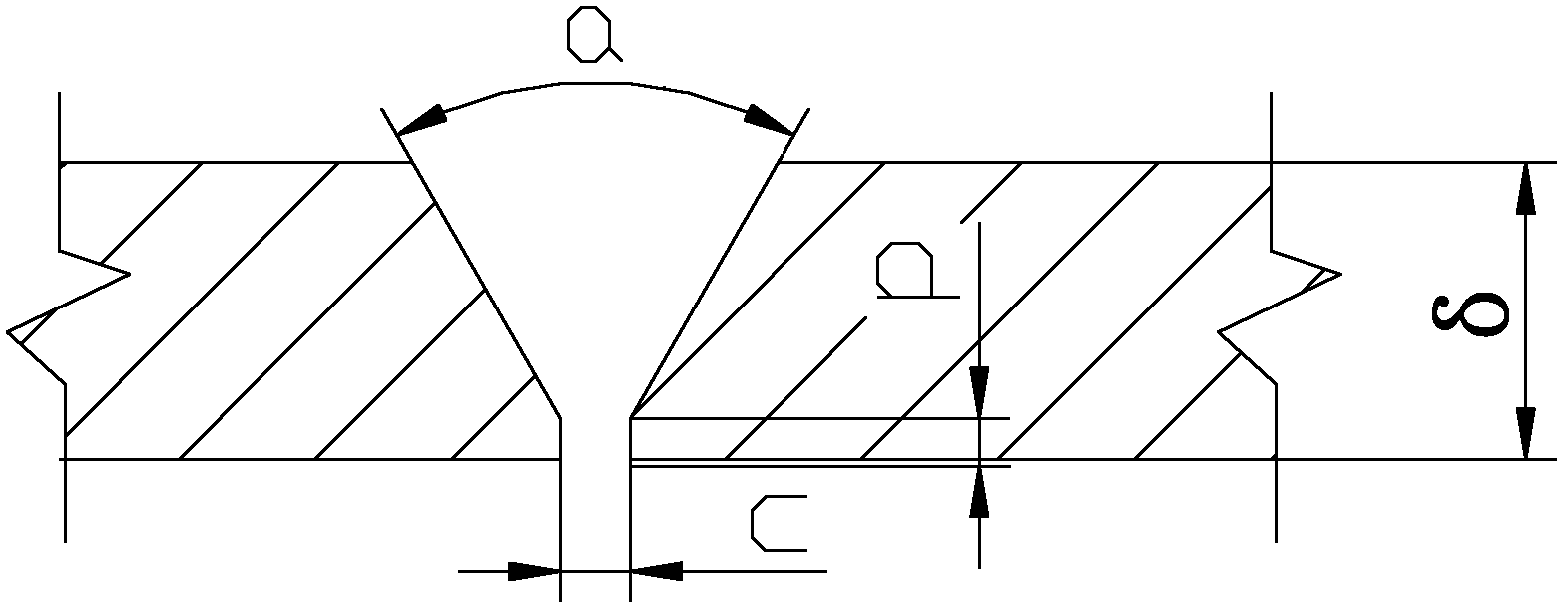

[0045] 1) The bevel form used is V-shape, and the bevel angle is α=60°, please refer to figure 1 .

[0046] 2) The pair gap is 2mm.

[0047] 3) The length of the positioning spot weld is 10mm and the thickness is 2mm.

[0048] 4) The welding process parameters are shown in Table 2.

[0049] Table 2 φ219×28.58mm chrome-molybdenum steel P22 pipeline submerged arc welding welding process parameters

[0050]

Embodiment 3

[0052] The welding process of submerged arc welding of φ219×26mm chrome-molybdenum steel P11 pipeline is the same as that of Example 1, except that:

[0053]1) The bevel form used is V-shape, and the bevel angle is α=60°, please refer to figure 1 , the group pair gap is 2mm.

[0054] 2) The length of the tack weld is 10mm and the thickness is 3mm.

[0055] 3) The preheating temperature before welding is 150℃~250℃.

[0056] 4) The welding wire grade selected for filling and cap welding is CHW-S11, the flux is SJ105, and the particle size is 10-60 mesh.

[0057] 5) The welding process parameters are shown in Table 3.

[0058] Table 3 φ219×26mm chrome molybdenum steel P11 pipeline submerged arc welding welding process parameters

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com