Method for checking and finishing plate blank by using flame

A slab and finishing technology, applied in the field of inspection and finishing of steel plate slab surface defects and subcutaneous defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

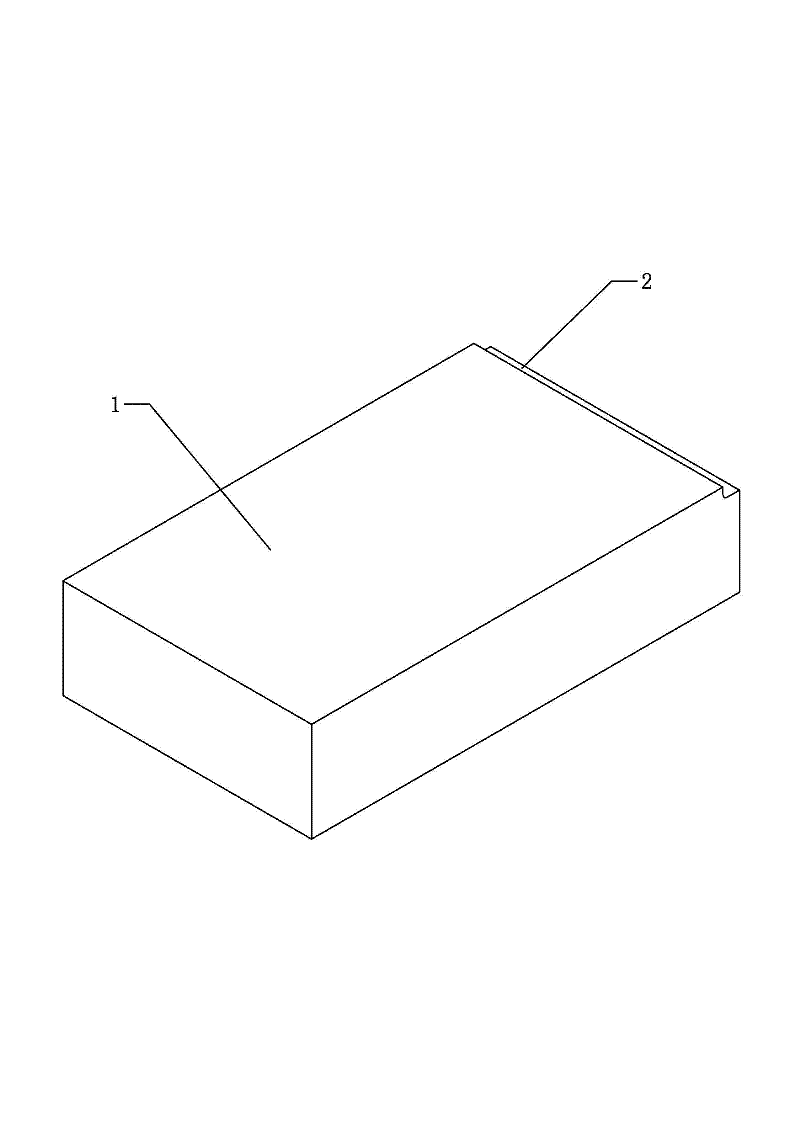

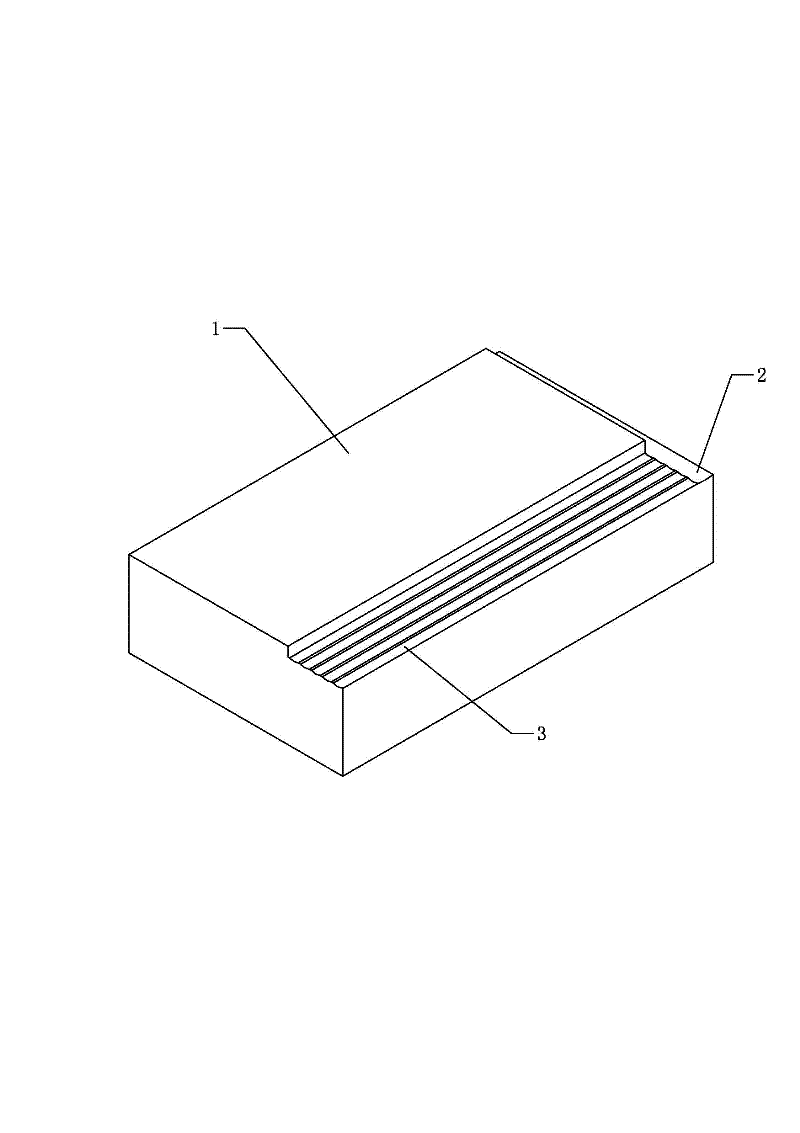

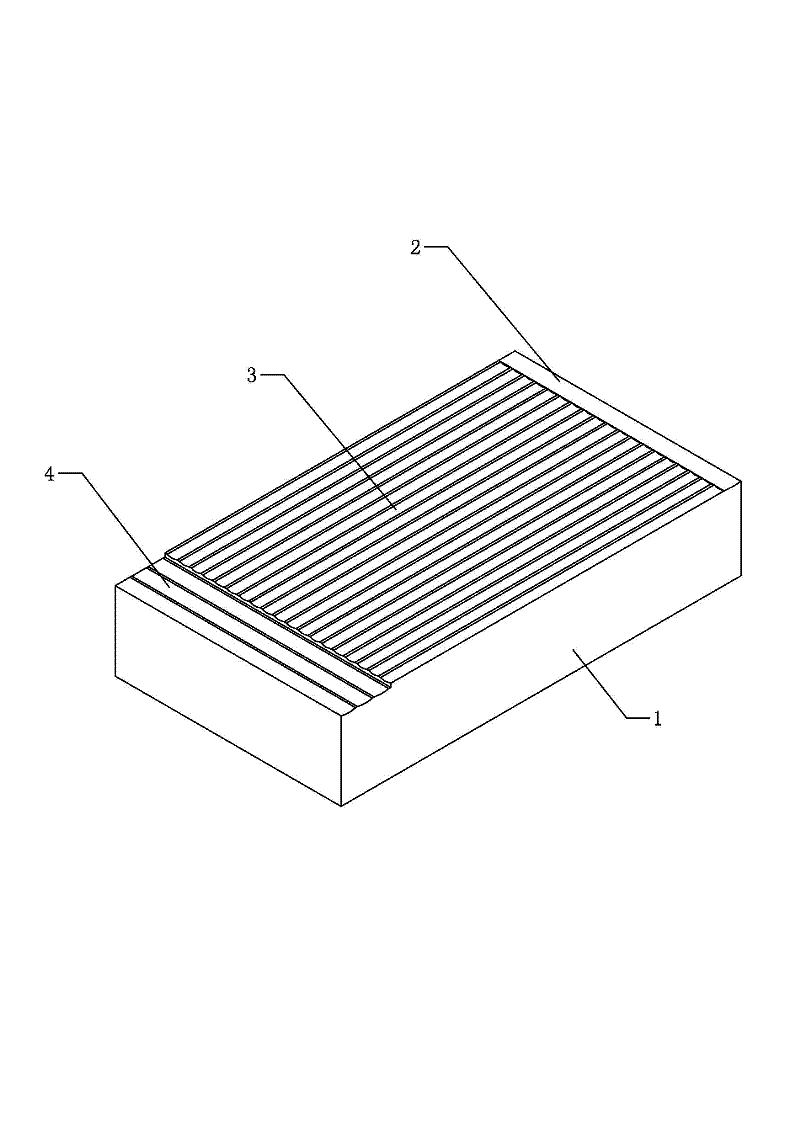

[0021] Embodiment 1: as figure 1 , figure 2 As shown, a slab flame inspection and finishing method includes the following steps: A) Transverse peeling: starting from the end edge of any end of the slab 1, the surface of the slab 1 is flame-cleaned in a transverse direction, and the end of the slab 1 is A horizontal strip ladder 2 is formed on the surface, the depth of the horizontal strip ladder 2 is 1-3mm, and the depth of the horizontal strip ladder 2 in the present invention is 2mm; B) Longitudinal peeling: starting from the bottom surface of the horizontal strip ladder 2 The surface of the slab 1 is flame-cleaned until the other end of the slab 1, that is, the flame is peeled once from the bottom surface of the horizontal strip-shaped step 2 along the longitudinal direction of the slab 1 by tilting the cutting nozzle of the flame-cleaning gun to form a longitudinal strip. Groove 3, the width of the longitudinal strip groove 3 is 5cm, the depth is 2mm, then return to the...

Embodiment 2

[0023] Such as figure 1 , figure 2 As shown, a slab 1 flame inspection and finishing method includes the following steps: A) Transverse peeling: starting from the end edge of any end of the slab 1, the surface of the slab 1 is flame-cleaned in a transverse direction, and the slab 1 end is A horizontal strip-like ladder 2 is formed on the upper surface, the depth of the horizontal strip-like ladder 2 is 1-3mm, and the depth of the horizontal strip-like ladder 2 of the present invention is 1mm; B) Vertical peeling: start from the bottom surface of the horizontal strip-like ladder 2 Perform flame cleaning on the surface of the slab 1 until the other end of the slab 1, that is, through the inclination of the cutting nozzle of the flame cleaning gun, the flame starts from the bottom surface of the horizontal strip step 2 and peels once along the longitudinal direction of the slab 1 to form a longitudinal strip. Strip groove 3, the width of this longitudinal strip groove 3 is 4cm...

Embodiment 3

[0025] Such as figure 1 , figure 2As shown, a slab 1 flame inspection and finishing method includes the following steps: A) Transverse peeling: starting from the end edge of any end of the slab 1, the surface of the slab 1 is flame-cleaned in a transverse direction, and the slab 1 end is A horizontal strip-like step 2 is formed on the surface of the body, the depth of the transverse strip-like step 2 is 1-3mm, and the depth of the horizontal strip-like step 2 of the present invention is 3mm; B) Vertical peeling: start from the bottom surface of the transverse strip-like step 2 Perform flame cleaning on the surface of the slab 1 until the other end of the slab 1, that is, through the inclination of the cutting nozzle of the flame cleaning gun, the flame starts from the bottom surface of the horizontal strip step 2 and peels the slab 1 longitudinally in one direction to form a longitudinal strip. Strip groove 3, the width of this longitudinal strip groove 3 is 8cm, and the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com