Solvent bondable thermoplastic elastomers

A thermoplastic elastomer and thermoplastic material technology, applied in the field of medical tubes, can solve the problems of plasticizer migration, unfavorable halogen-containing compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

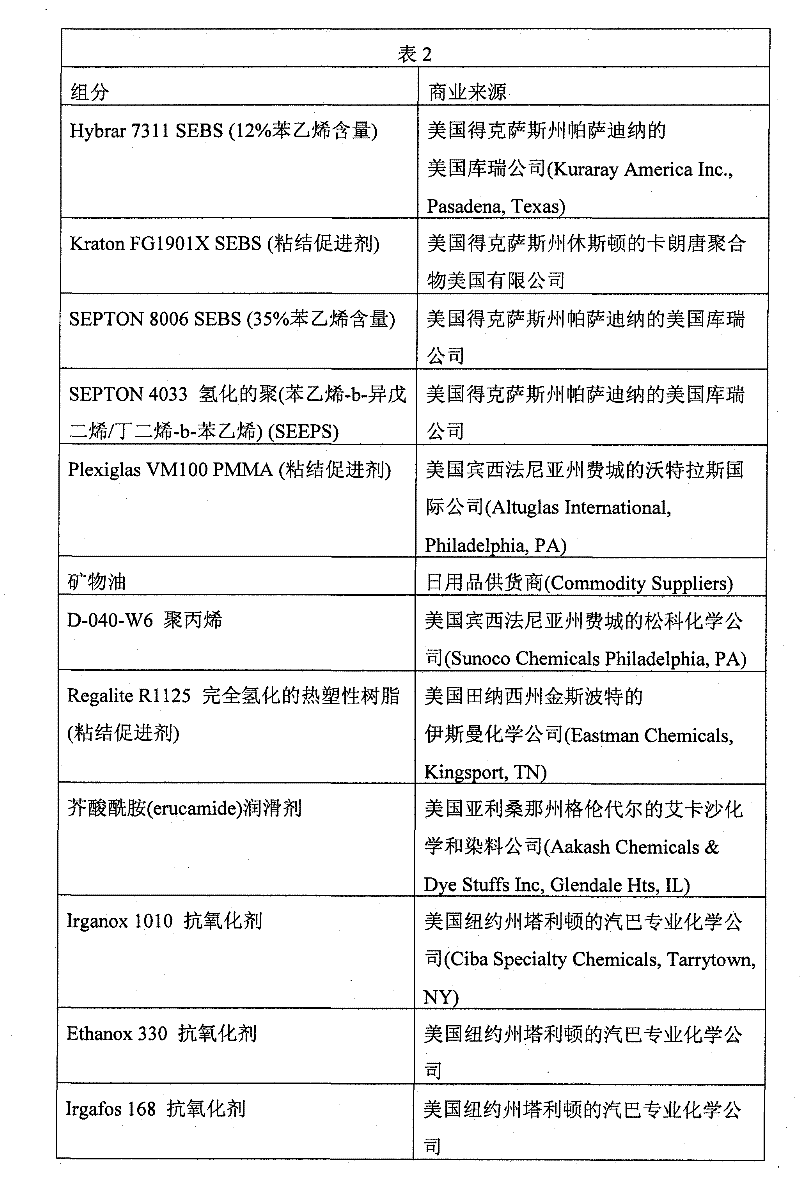

[0040] Table 2 shows the source of components for each example.

[0041]

[0042]

[0043] All the components of each example and each comparative example were delivered to the feed port of a twin-screw extruder with a mixing speed of 400 rpm and a temperature of: 360°F in zone 1, 380°F in zone 2, 400°F in zone 3 ℉, Zone 4 430℉, Zone 5-8 and Die 400℉. After compounding, pellets were formed, molded into tensile testing rods or plates, or extruded into tubes with an outside diameter of 0.145-0.168 inches and an inside diameter of 0.100-0.118 inches, or as indicated in the table below.

[0044] Table 3 shows the test methods used and the results obtained. Standard physical property tests were performed using standard tensile test bars cut from panels molded from the compound. Haze tests were performed using 3.17 mm thickness panels molded from the compound. Additionally, a solvent bond test was performed to test the adhesion of solvent bonds or welds of tubes made from t...

Embodiment 9-10 and comparative example F-G

[0064] Table 4 shows the effect of the type of hydrogenated styrene butadiene copolymer on the properties of pipes made from these compounds. All components were premixed using a Henschel mixer and then compounded using a co-rotating twin-screw extruder. The extrudate was pelletized with a Gala underwater pelletizer. To determine the mechanical properties of the compounds, plates (12.7 cm x 15.2 cm x 0.32 cm) were molded using an injection molding machine using the following temperature profile and process conditions:

[0065] Temperature: 227 / 227 / 204 / 182°C

[0066] Process conditions: 15.17 MPa, 120 rpm, 0.5 seconds, 6.2 MPa / 6.2 MPa, 5 / 5 / 25 holding time / stuffing time / cooling time, in seconds.

[0067] The following physical properties were tested according to the following standard methods: specific gravity: ASTM D792; hardness (Shore A): ASTM D2240, 10 second delay; capillary rheology: determined at 200°C; tensile properties: ASTM D412, die C. The specialized test methods...

Embodiment 11-18

[0075] Other embodiments of the present invention are obtained from Examples 11-16. Compounds were prepared and tested in the same manner as in Examples 9 and 10. Table 5 shows the recipes and results. Erucamide wax was added in these examples to help the circumference of the tube recover after the clamping pressure was removed.

[0076]

[0077]

[0078] Examples 11-18 demonstrate that all formulations process well into tubes, the hardness and tensile modulus of the compounds vary slightly depending on the type of rubber and polypropylene. The pull-out force depends on the hardness and / or modulus of the compound. The pull-out energy seems to depend on the type of polypropylene used in the compound, the higher the melt flow rate of the polypropylene, the lower the pull-out energy. The presence of wax did not affect the solvent bondability of the tube, but did improve the clamp recovery time interval.

[0079] Tubes prepared from these formulations of Examples 11-18 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com