Phenol resin for shell molding, process for production of the resin, resin-coated sand for shell molding, and molds obtained using same

A phenolic resin and manufacturing method technology, applied in the directions of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of undisclosed casting mold crack tar generation, mold corrosion, undisclosed and other problems, to solve the problem of gas defects, reduce The amount of tar generated and the effect of improving shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

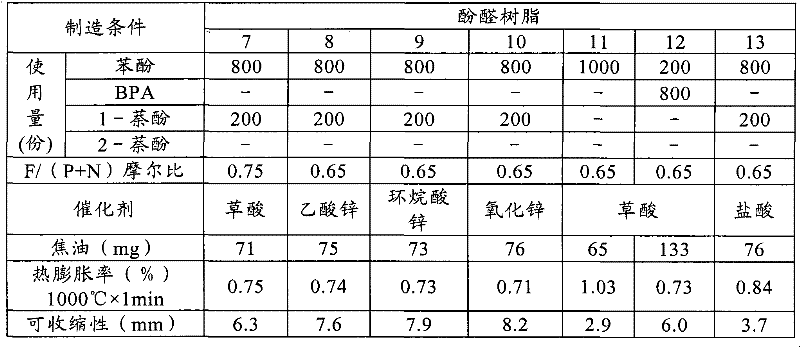

[0037] Hereinafter, several embodiments of the present invention are given to illustrate the present invention more specifically, and it goes without saying that the present invention is not limited by the contents described in these embodiments. In addition, it should be understood that in the present invention, in addition to the following embodiments, and further in addition to the above specific description, it also includes various changes based on the knowledge of those skilled in the art within the scope of not departing from the gist of the present invention , corrections, improvements, etc.

[0038] In addition, "part" and "%" in the following description represent "parts by mass" and "% by mass", respectively, unless otherwise specified. In addition, various characteristics of the produced shell type RCS were measured according to the following test methods.

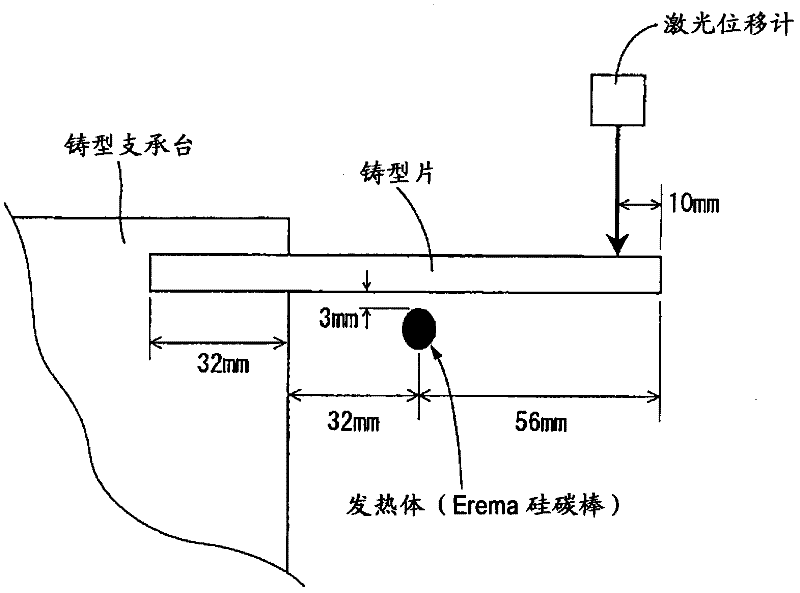

[0039] -Determination of tar generation amount-

[0040] After putting 4 samples for mold strength measure...

manufacture example 1-

[0048] Put 800 parts of phenol, 200 parts of 1-naphthol, 411 parts of 47% formalin and 3 parts of oxalic acid into the reaction vessel equipped with a thermometer, a stirring device and a condenser. Next, the temperature of the reaction vessel was slowly raised, and after reaching the reflux temperature, the reflux reaction was carried out for 90 minutes, further dehydration was carried out under normal pressure, and then heated to 180° C. under reduced pressure to remove unreacted phenol, thereby obtaining phenolic resin 1 . The number average molecular weight of the phenolic resin 1 is 850.

[0049] -Manufacturing example 2-

[0050] Phenolic resin 2 was obtained in the same procedure as in Production Example 1, except that 950 parts of phenol, 50 parts of 1-naphthol, 434 parts of 47% formalin, and 3 parts of oxalic acid were added.

manufacture example 3-

[0052] Phenolic resin 3 was obtained in the same procedure as in Production Example 1 except that 700 parts of phenol, 300 parts of 1-naphthol, 395 parts of 47% formalin, and 3 parts of oxalic acid were added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com