Preparation method of oxygen-stabilized yttrium fluoride film

A yttrium fluoride and stable technology, which is applied in the field of preparation of yttrium fluoride thin films, can solve the problems of optical constant distortion, poor optical performance, and the thin film is easy to fall off, and achieves the effects of improving distortion, good optical performance and low refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific Embodiment 1: The preparation method of the oxygen-stabilized yttrium fluoride thin film in this embodiment is realized according to the following steps: 1. The ZnS substrate is ultrasonically cleaned with acetone for 15 to 30 minutes, cleaned with alcohol for 15 to 30 minutes, and then cleaned with deionized water for 30 minutes , and then place the ZnS substrate on the rotating heating table in the magnetron sputtering vacuum chamber, and evacuate the vacuum chamber to a vacuum degree of 1.0×10 through the vacuum acquisition system. -4 ~9.9×10 -4 Pa, then heated to 25-1000°C and kept warm for 30-120min; 2. Introduce Ar gas into the vacuum chamber until the pressure in the vacuum chamber is 3-5Pa, and perform backsplash cleaning on the surface of the ZnS substrate for 10-20min; 3. After splash cleaning, apply sputtering power to start the ignition, the sputtering power is 60-500 watts, pre-sputtering for 20-50 minutes, and then turn on O 2 Flow agent switch, ...

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the ZnS substrate is ultrasonically cleaned with acetone for 15 minutes, and cleaned with alcohol for 15 minutes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, the ZnS substrate is ultrasonically cleaned with acetone for 30 minutes, and cleaned with alcohol for 30 minutes. Other steps and parameters are the same as those in Embodiment 1.

PUM

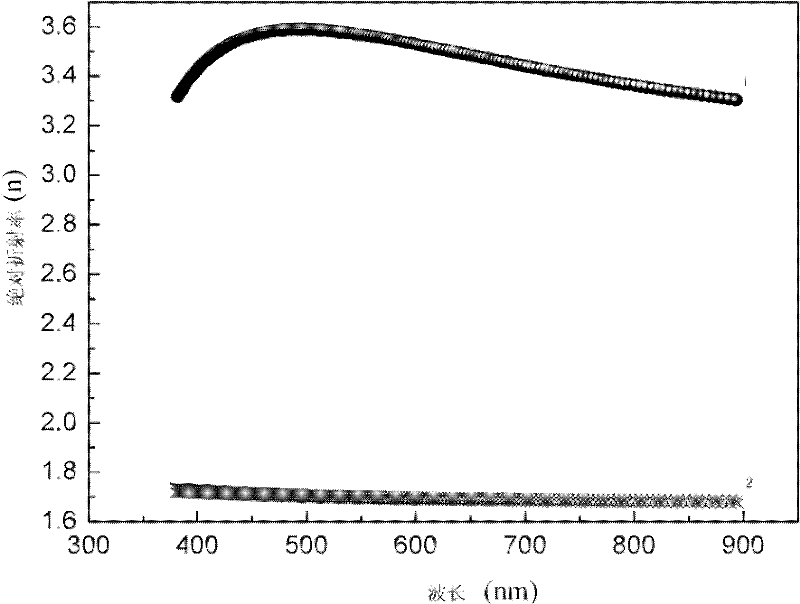

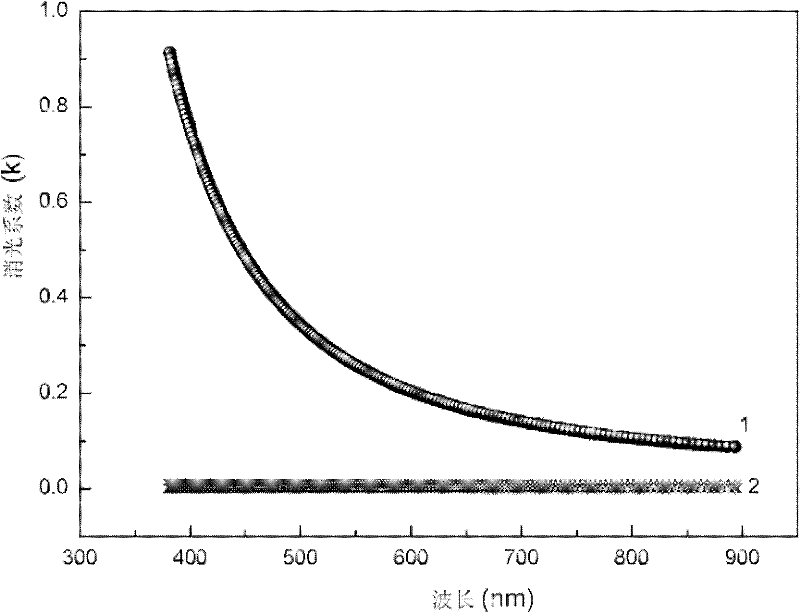

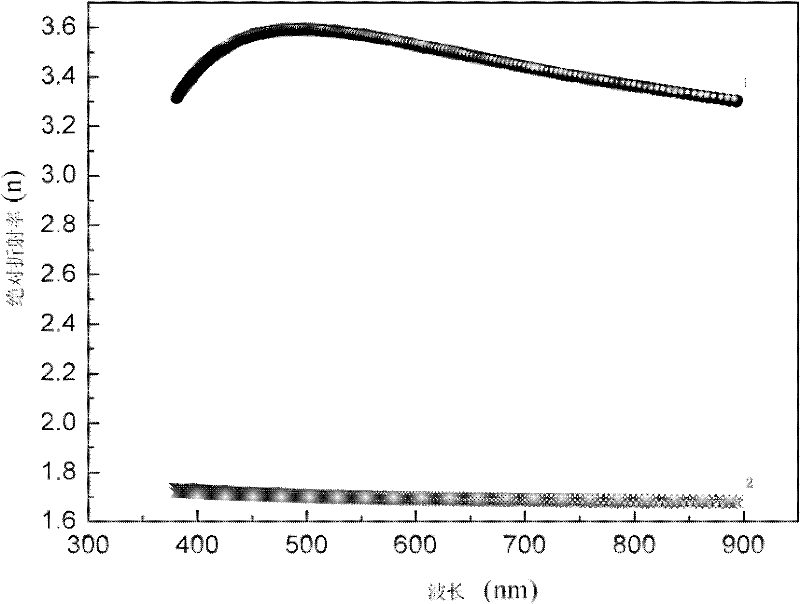

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com