Flue gas circulation and biomass energy combined iron ore sintering method

A technology of biomass energy and flue gas circulation, which is applied in the field of iron ore sintering, can solve the problems of high pollutant content in sintering flue gas, lack of emission reduction technology, and large equipment footprint, so as to reduce solid fuel consumption and SO2 content Low, emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

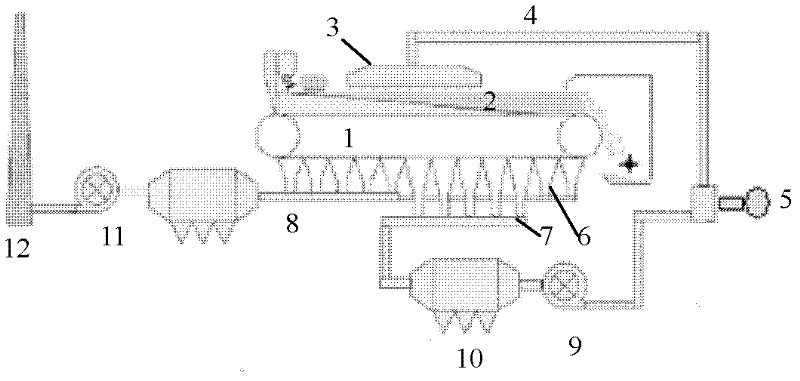

Method used

Image

Examples

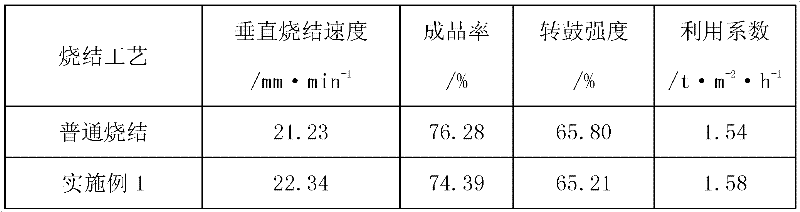

Embodiment 1

[0028] According to the mass ratio of mixing 60.73% of iron ore, 5.58% of dolomite, 2.16% of limestone, 4.62% of quicklime, 23.08% of sintering return, and 3.85% of biomass charcoal (the chemical composition of sintered ore is: TFe57.5%, SiO 2 4.82%, R2.0, MgO2.0%). The density of biomass charcoal used is 1.2g / cm 3 , The fixed carbon content is 83.74%, the volatile matter is 7.55%, the calorific value is 30.77MJ / kg, the average particle size is 2.41mm and the content of -0.5mm is 23.58%. The biomass charcoal is mixed with other sintering raw materials, granulated, and distributed to the sintering machine. The flue gas is drawn from the sintering machine No. 16-22 wind boxes (a total of 24 wind boxes) to circulate to the sintering material layer using biomass as fuel. The circulating volume accounts for 30% of the total flue gas, and the fume hood accounts for 45% of the sintering machine. And add air to make the circulating flue gas composition O 2 14%, CO 2 5%, H 2 O(g) 7%, an...

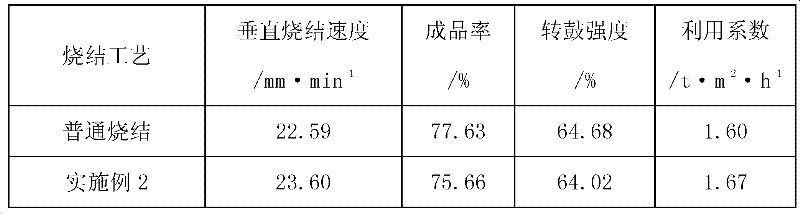

Embodiment 2

[0033] According to the mass ratio of mixing iron ore 61.03%, dolomite 6.12%, limestone 2.27%, quicklime 3.50%, sintering return 23.08%, and biomass char 2 5.05%, R1.90, MgO2.20%). The density of biomass charcoal used is 1.3g / cm 3 , The fixed carbon content is 86.31%, the volatile matter is 5.22%, the calorific value is 31.89MJ / kg, the average particle size is 2.55mm and the -0.5mm content is 22.21%. The biomass charcoal is mixed with other sintering raw materials, granulated, and distributed to the sintering machine. The flue gas is drawn from the 15-22 wind boxes of the sintering machine (23 wind boxes in total) to circulate to the sintering material layer using biomass as fuel. The circulating volume accounts for 38% of the total flue gas, and the fume hood accounts for 50% of the sintering machine. And add air to make the circulating flue gas composition O 2 13%, CO 2 6%, H 2 O(g) 8%, the flue gas temperature is 180°C.

[0034] The output and quality indicators of sintered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com