Modified lignin and urea-formaldehyde resin synthesized from same and preparation methods of modified lignin and urea-formaldehyde resin

A urea-formaldehyde resin, lignin technology, applied in the direction of adhesive types, aldehyde/ketone condensation polymer adhesives, adhesives, etc. Adhesive manufacturing cost and other issues, to achieve the effect of good market prospects, high bonding strength, moderate storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

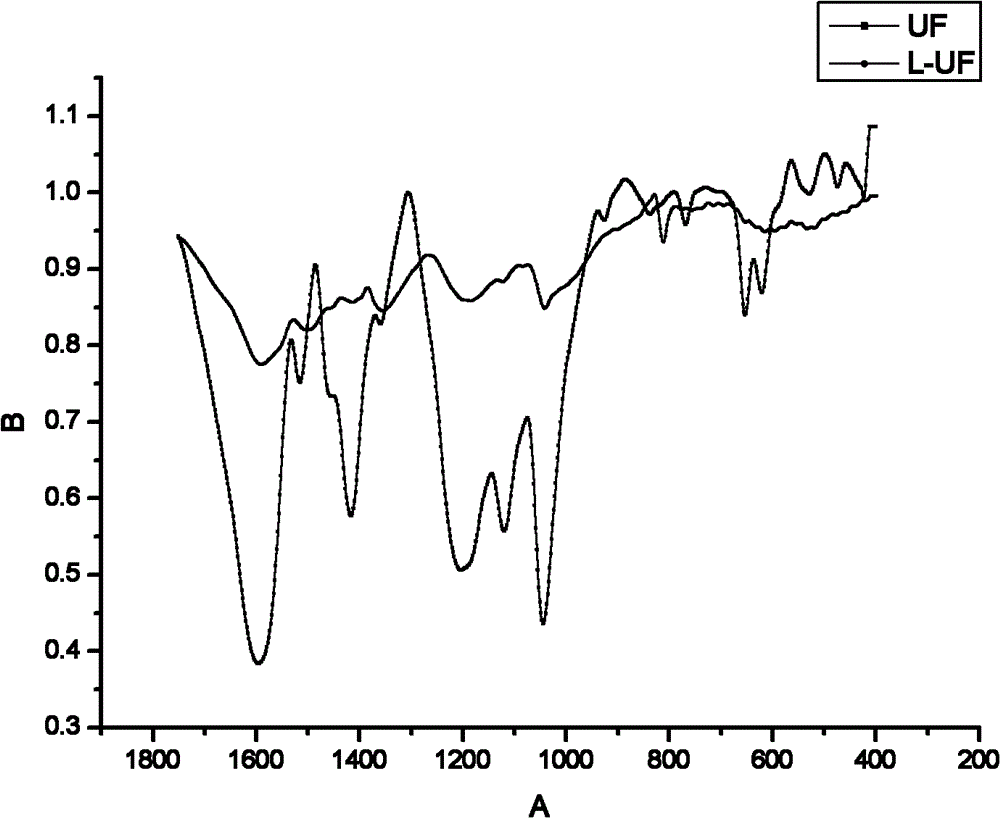

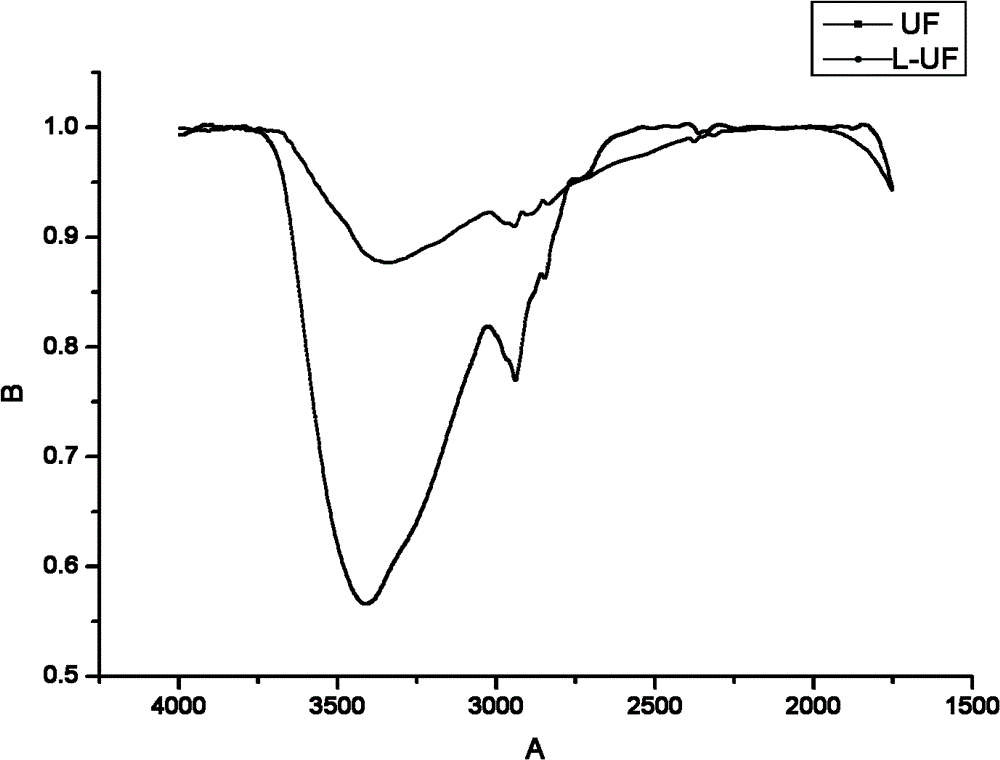

Image

Examples

Embodiment 1

[0036] Add 70g of sodium lignosulfonate to the beaker, add 85.5g of water to prepare an aqueous solution, add 0.2g of 20% sodium hydroxide aqueous solution, shake well, and let stand for 12 hours.

[0037] Add 141g of lignin solution with a mass fraction of 45% into a 500ml four-neck flask, turn on the stirring device, raise the temperature to 70°C, add 30g of formaldehyde solution with a mass fraction of 37.45%, keep the pH of the system at 9.5, and raise the temperature to 70°C After ℃, keep warm for 60min; add 19.5g of melamine to adjust the pH of the system to 9.5, react for 3 hours, cool and discharge.

[0038]In a 500ml four-necked bottle equipped with a reflux condensing device and a stirring device, add 168.39 g of 37.45% formaldehyde aqueous solution and 63.03 g of urea, turn on the stirring device, add 20% aqueous sodium hydroxide solution dropwise to adjust the pH of the system to 9.2, and start heating at the same time ;When the temperature rises to 85°C, keep it w...

Embodiment 2

[0040] In the synthesis of modified lignin in this embodiment, the mass fraction of sodium lignosulfonate aqueous solution is 40%, and the addition amount is 120 parts by weight, and the others are the same as in Example 1.

Embodiment 3

[0042] In the synthesis of modified lignin in this embodiment, the mass fraction of sodium lignosulfonate aqueous solution is 40%, and the addition amount is 160 parts by weight, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com