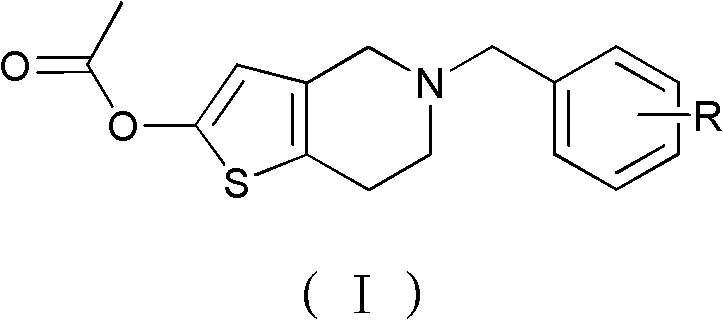

Thienopyridine ester derivative containing nitrile group, its preparation method and its purpose

A kind of pyridine, nitrile technology, applied in the field of medicine, can solve the problem of patients with heavy bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

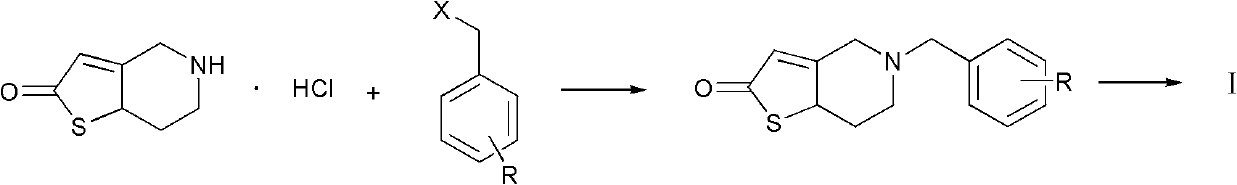

Method used

Image

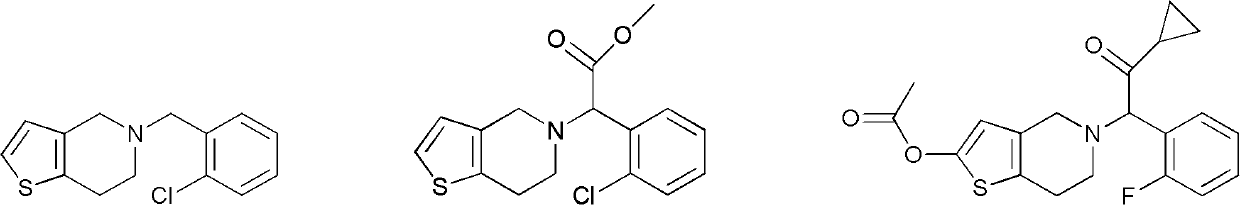

Examples

Embodiment 1

[0032] intermediate 1 preparation of

[0033]

[0034] Add 19.2 g of 5,6,7,7a-tetrahydrothieno[3,2-c]pyridin-2(4H)-one into a reaction flask equipped with stirring, condenser and thermometer, and dissolve it with 70 mL of acetonitrile , cooled to -10°C with stirring, and 41.5 g of anhydrous potassium carbonate was added. 19.6 g of 2-cyanobenzyl bromide was added to the reaction system in batches, and after the addition, the temperature was raised to 45° C. to continue the reaction for 4 h (the plate showed that the reaction was complete). Filter, evaporate the filtrate to dryness of acetonitrile, add 50mL of dichloromethane, wash the reaction solution with 3×50mL of water, separate the dichloromethane layer, fully dry it with anhydrous sodium sulfate, filter, and evaporate the dichloromethane under reduced pressure to obtain Yellow oily product 22.6 g (HPLC: 97.2%). Rf = 0.47 [single site, developer: v (petroleum ether): v (ethyl acetate) = 1:2]. MS, m / Z: 270.0 (M).

Embodiment 2

[0036] intermediate 2 preparation of

[0037]

[0038]Add 5,6,7,7a-tetrahydrothieno[3,2-c]pyridin-2(4H)-one 19.2g in the reaction flask equipped with stirring, condenser and thermometer, and dissolve This was dispersed, cooled to 0° C. with stirring, and 30.4 g of triethylamine was added. 15.2 g of 3-cyanobenzyl chloride was added to the reaction system in batches, and after the addition, the temperature was raised to reflux to continue the reaction for 5 h (the plate showed that the reaction was complete). The reaction solution was washed with 3×80 mL of water, and the dichloromethane layer was separated, fully dried with anhydrous sodium sulfate, filtered, and the dichloromethane was evaporated under reduced pressure to obtain 20.8 g of a light yellow solid product (HPLC: 96.4%). Rf = 0.45 [single site, developer: v (petroleum ether): v (ethyl acetate) = 1:2]. MS, m / Z: 270.0 (M).

Embodiment 3

[0040] intermediate 3 preparation of

[0041]

[0042] Add 19.2 g of 5,6,7,7a-tetrahydrothieno[3,2-c]pyridin-2(4H)-one into a reaction flask equipped with stirring, condenser and thermometer, and disperse it with 65mL of toluene , cooled to 10°C with stirring, and 23.7 g of pyridine was added. 19.6 g of 4-cyanobenzyl bromide was added to the reaction system in batches, and after the addition, the temperature was raised to 95° C. to continue the reaction for 2.5 h (the plate showed that the reaction was complete). The reaction solution was washed with 3×50 mL of water, the toluene layer was separated, fully dried with anhydrous sodium sulfate, filtered, and the toluene was evaporated under reduced pressure to obtain 21.4 g of a yellow oily product (HPLC: 94.2%). Rf = 0.41 [single point, developer: v (petroleum ether): v (ethyl acetate) = 1:2]. MS, m / Z: 270.0 (M).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com