Electrophoretic display

a technology of electrophoretic display and film structure, applied in the field of electrophoretic display, can solve the problems of low production efficiency, lack of structure integrity and depth control, and certain disadvantages of continuous liquid phase structure, and achieve the effect of improving mechanical properties and structural integrity of film structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

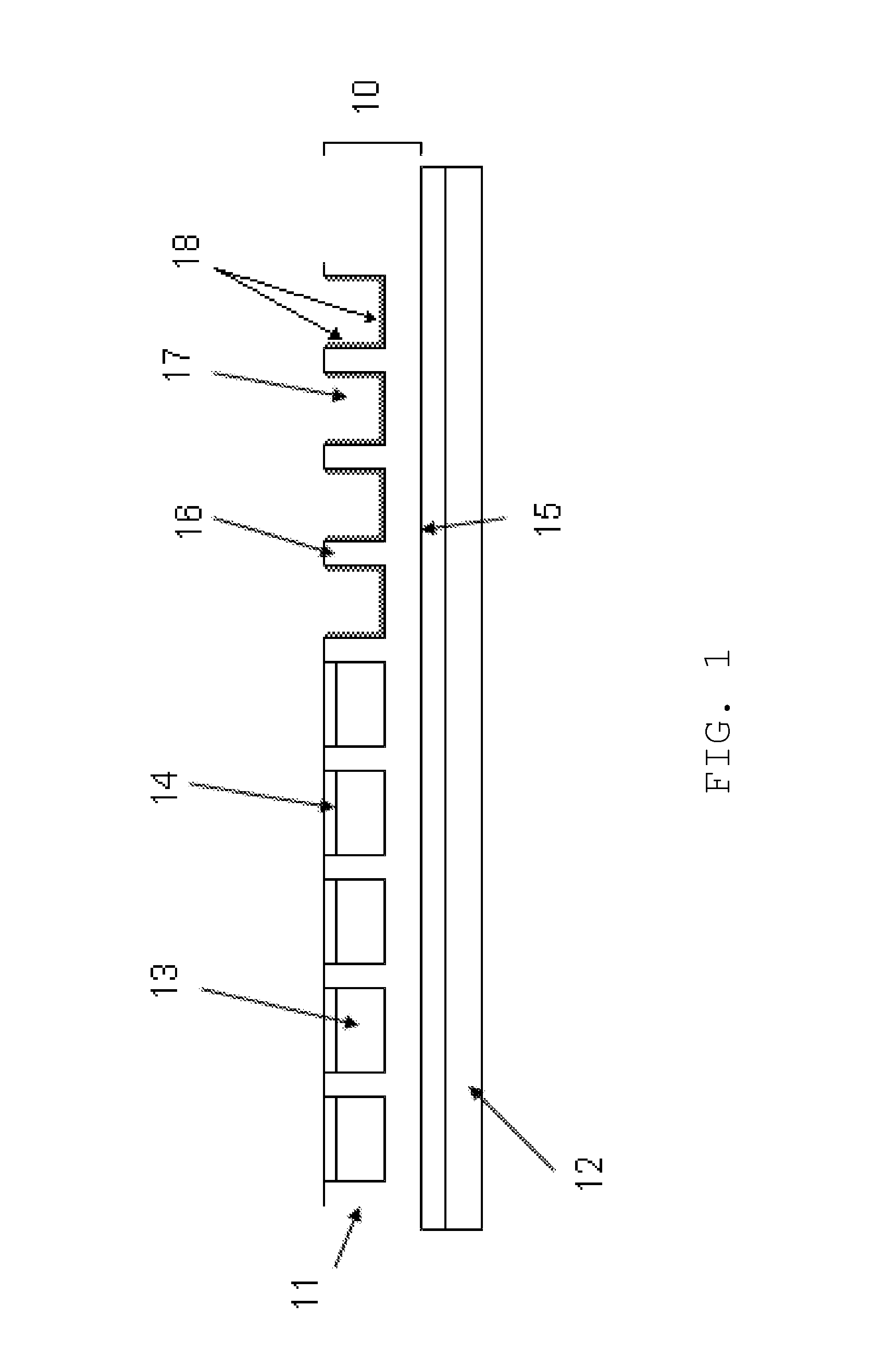

[0020]FIG. 1 illustrates the film structure (10), an electrophoretic display, which comprises one or more microcups (11). The microcups comprise partition walls (16) and top openings (17). The film structure (10) may be formed on a substrate layer (12) which may optionally comprise an electrode layer (not shown). There may also be an optional primer layer (15) between the microcups and the substrate layer (12). The microcups are filled with a liquid composition (13) and top-sealed with a polymeric sealing layer (14).

[0021]1. Formation of the Microcups

[0022](a) Microembossing

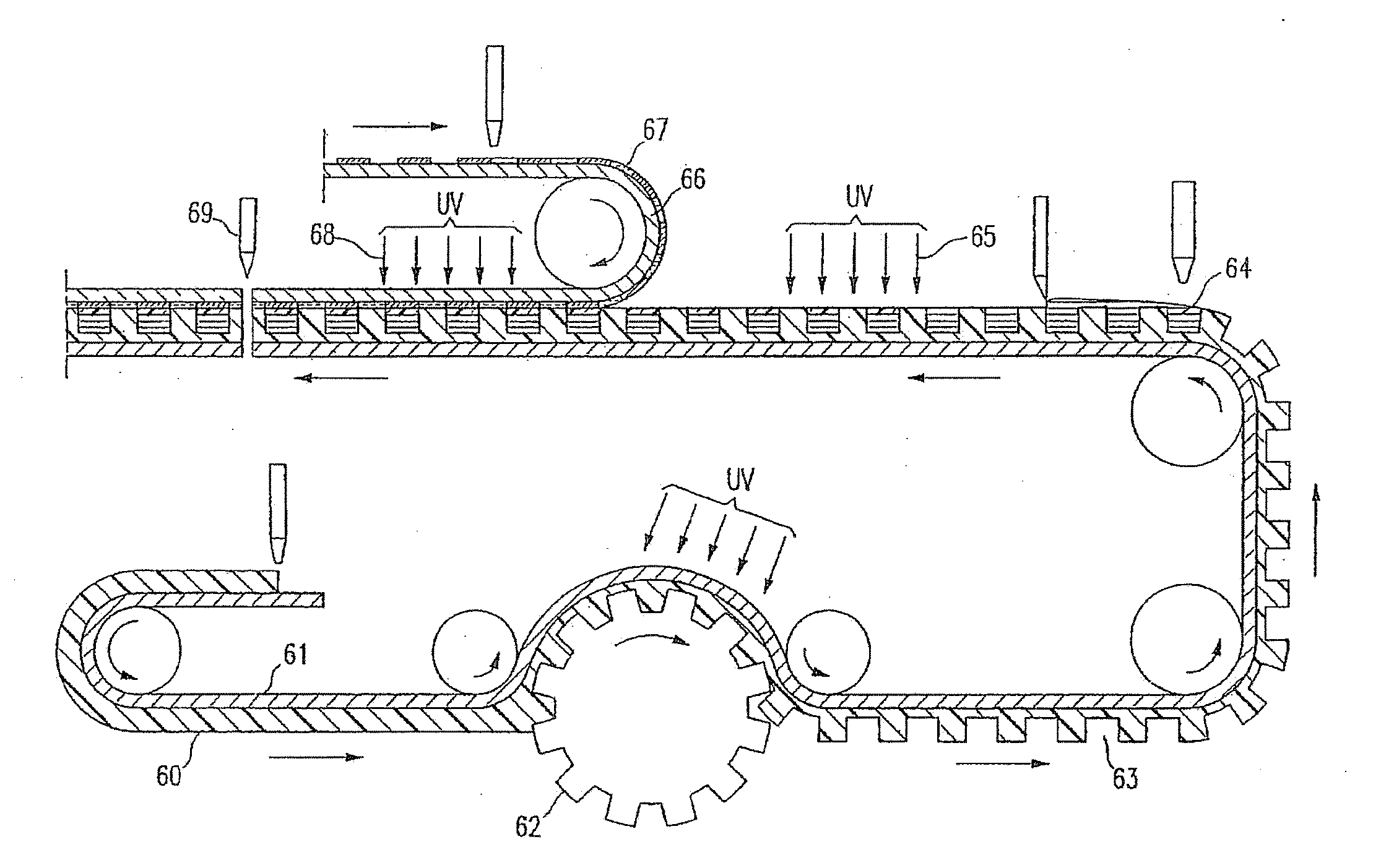

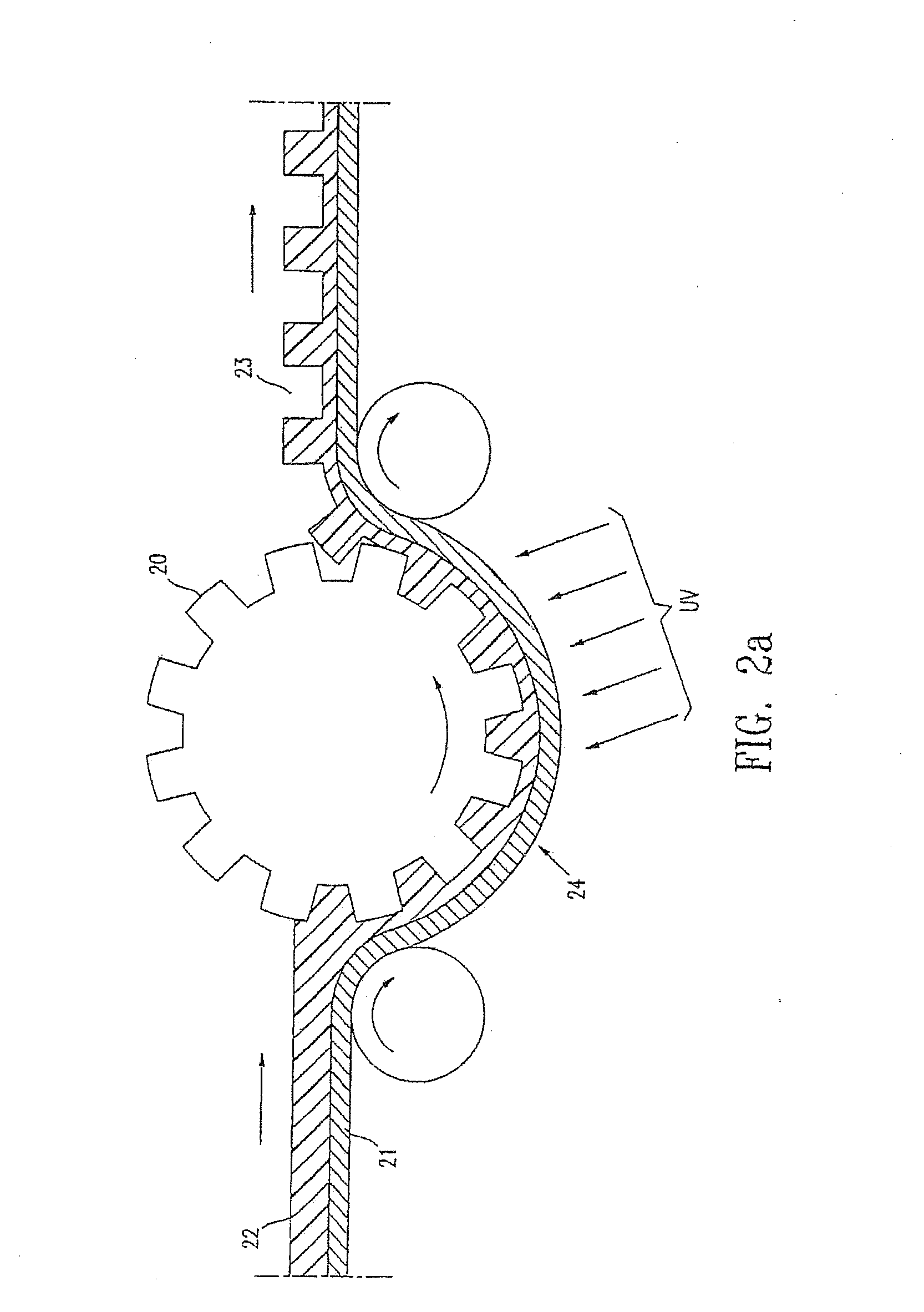

[0023]This processing step is shown in FIGS. 2a and 2b. A male mold (20) may be placed either above (FIG. 2a) or below (FIG. 2b) the web (24). The microcups may be formed on a flexible substrate layer (21). The substrate layer (21) may optionally comprise an electrode layer (not shown), which is suitable especially for display applications or other applications the operation of which involves the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Solubility (ppm) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com