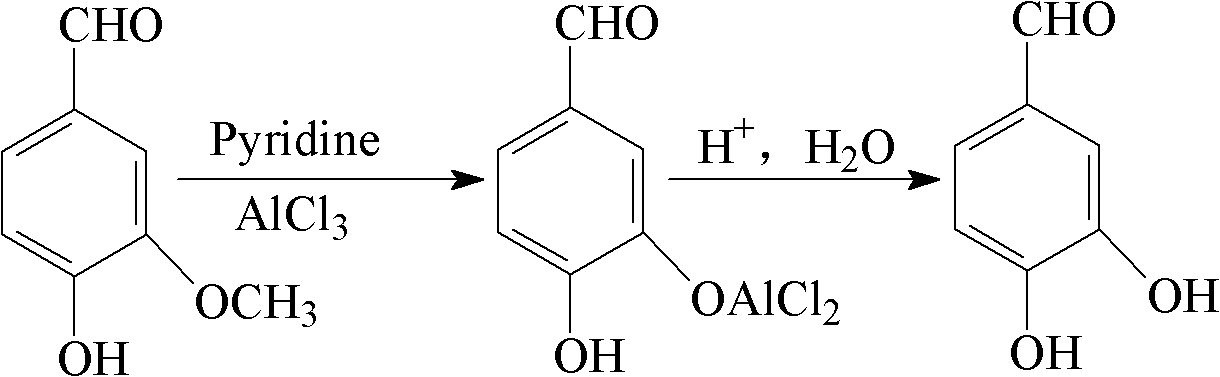

Method for preparing protocatechuic aldehyde from vanillin

A technology of protocatechuic aldehyde and vanillin, which is applied in the field of preparing protocatechuic aldehyde, can solve the problems of high energy consumption and long reaction time, and achieve the effects of increasing reaction temperature, good solubility, and reducing post-processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) add 7.8g (51mmol) vanillin (technical grade, China Chemical Industry Group Co., Ltd.) and 30ml dimethyl carbonate in the there-necked flask equipped with stirring and condensation reflux device, after fully stirring, add 9.4g (70mmol) ) anhydrous AlCl 3 ;

[0027] (2) After the solid is dissolved, place the three-necked flask in an ice-water bath, and keep its temperature at 0 to 5°C; add 13.5 ml of pyridine under stirring;

[0028] (3) the reaction system was warmed up to 80 ° C, and reacted for 4 hours;

[0029] (4) after the temperature of the reaction system is lowered to room temperature, add 70 ml of dilute hydrochloric acid with a mass fraction of 12% to pH 2 under stirring conditions, and continue to stir to stop the reaction after 1.0 hours;

[0030] (5) Pour the reaction solution into a separatory funnel, leave it to stand, extract unreacted vanillin in the water phase three times with dichloromethane (20ml×3), then dichloromethane is removed by distilla...

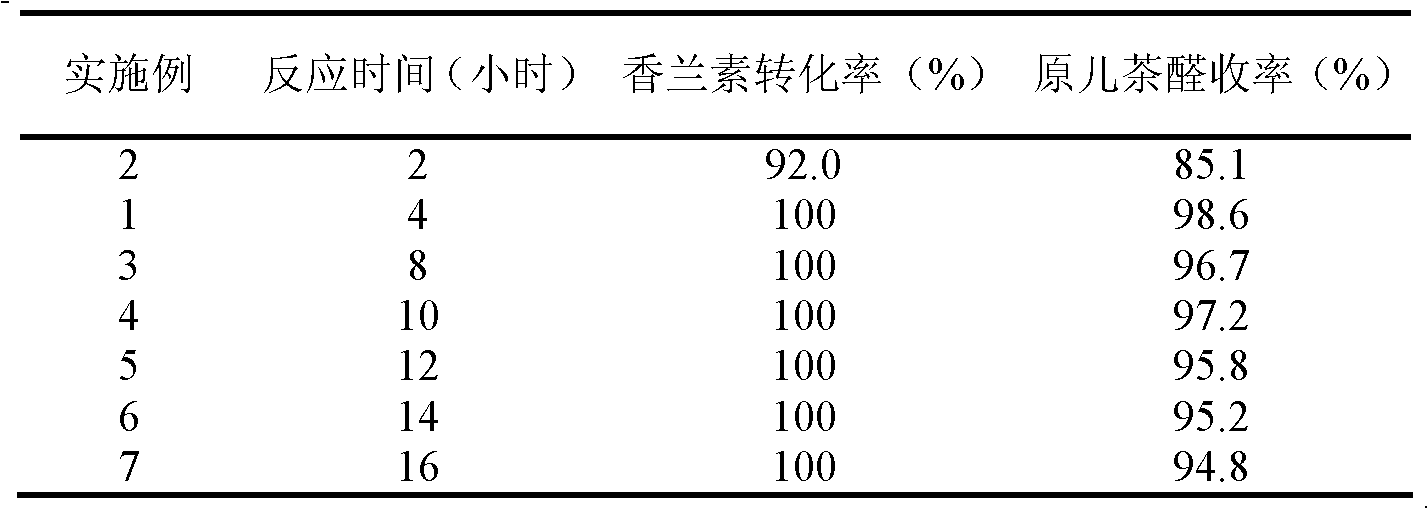

Embodiment 2~7

[0037] The chemical reagent consumption and the reaction steps are the same as in Example 1, but the reaction time in the step (3) is changed, and the reaction results are shown in Table 1.

[0038] Table 1 Influence of reaction time on the preparation of protocatechuic aldehyde from vanillin

[0039]

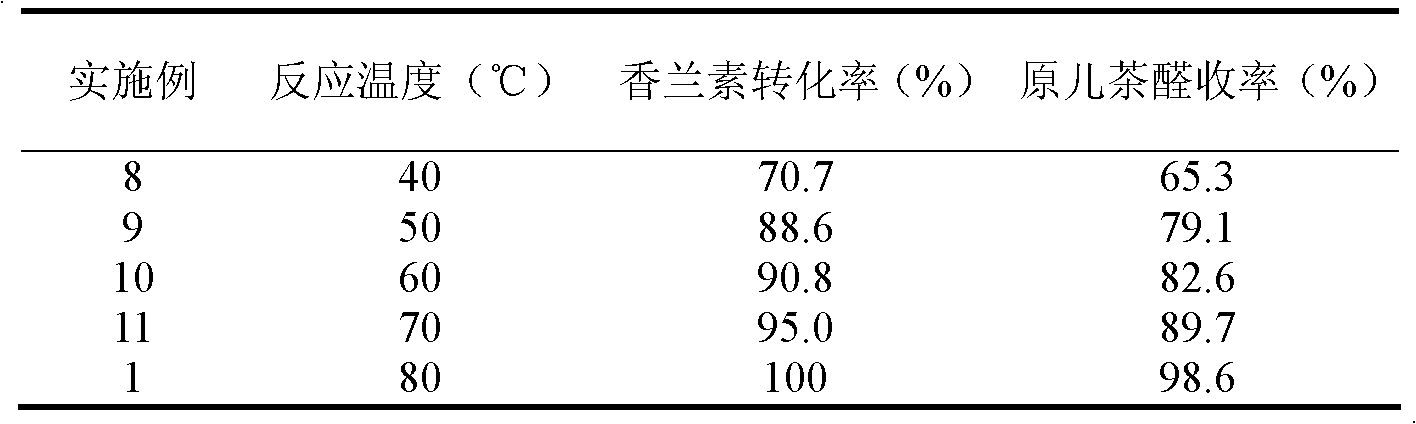

Embodiment 8~11

[0041] The chemical reagent consumption and the reaction steps are the same as in Example 1, but the reaction temperature in the step (3) is changed, and the reaction results are shown in Table 2.

[0042] Table 2 Influence of reaction temperature on the preparation of protocatechualdehyde from vanillin

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com