Multistage-absorption-type rotating packed bed

A technology of high-gravity rotating bed and rotating bed, which is applied in chemical/physical/physicochemical fixed reactors, dispersed particle separation, fractionation, etc., and can solve problems that affect the popularization and application of rotating beds, difficulty in popularization and high liquid-gas ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

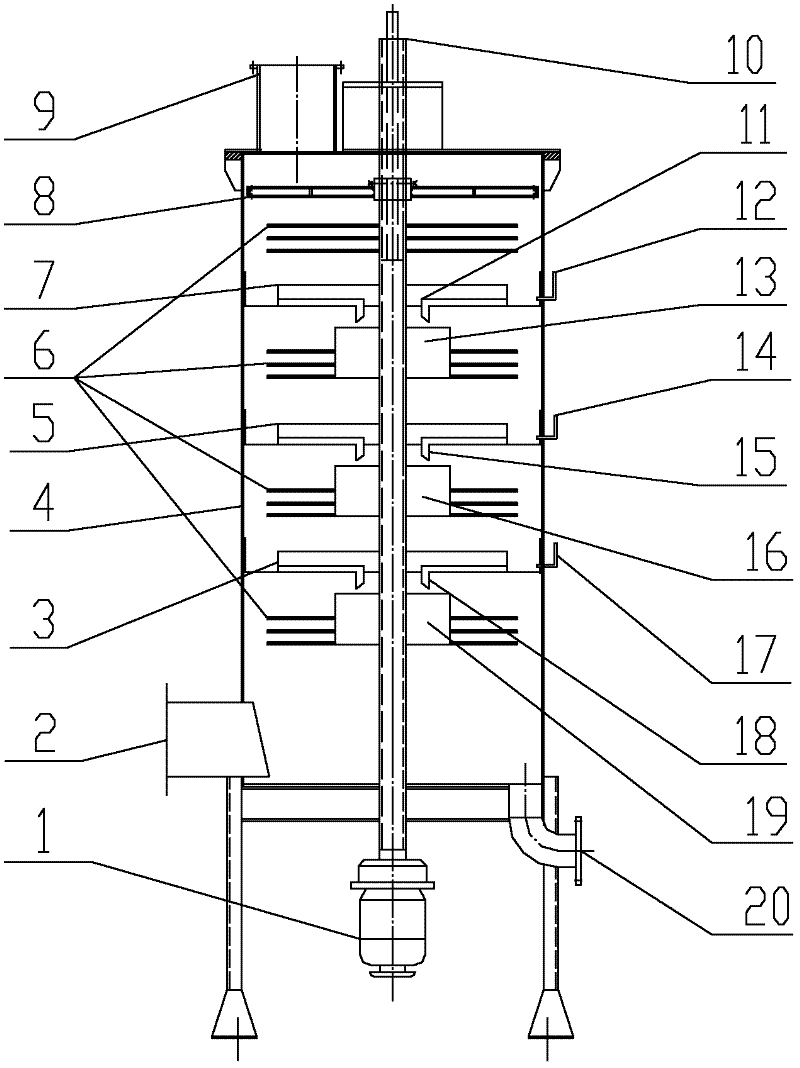

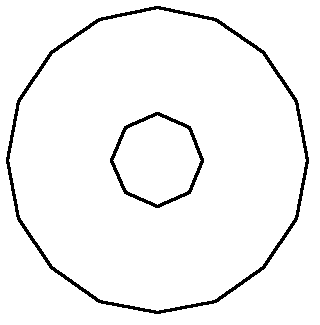

[0025] figure 1 A structural form of the multi-stage absorption high-gravity rotating bed of the present invention is shown. The multi-stage absorption high-gravity rotary bed includes a cylindrical shell 4, a motor 1, a rotating shaft 10, a four-stage flat screen packing group 6, three-stage liquid collection grooves 7, 5, and 3, and three-stage central distribution grooves 13, 16 , 19 and rotary demister 8. The rotating shaft 10 is vertically arranged in the center of the cylindrical housing 4 and connected with the motor 1 . The lower end of the housing 4 is provided with an air inlet 2 and the liquid outlet 20 , and the upper end of the housing 4 is provided with an air outlet 9 . The rotating shaft 10 is made of stainless steel seamless pipe, which is a hollow structure, and its upper end is provided with a liquid inlet; the first-level flat screen packing group is horizontally fixed on the upper end of the rotating shaft 10, and the first-level liquid sink groove 7 is f...

Embodiment 2

[0032] The difference from Example 1 is that this embodiment is composed of a three-stage flat screen packing group. The plane screen is made of PP as the skeleton, and the PE screen is arranged on it; the distance between each plane screen is 10mm, and the outer surface of the plane screen is The gap between the circumference and the inner wall of the housing 4 is 10mm. The distance between adjacent two-stage planar stencil packing groups is 300mm. The second and third level flat mesh panels are fixed on the central distribution groove by welding. The central distribution trough is bolted to the shaft. The sink groove is made of stainless steel, and there are 6 inside the groove stainless steel guide tube. In the second-level sink groove and the third-level sink groove, there are 4 The stainless steel connecting pipe connects the sump groove and the outside of the rotating bed. Part of the intermediate absorption liquid is exported out of the system through the third-l...

Embodiment 3

[0035] The difference from Example 1 is that this embodiment has three levels of packing groups of flat screen plates, the rotating shaft is a porous seamless stainless steel pipe, the distance between the plane screen plates is 12mm, and the distance between the outer circumference of the plane screen plates and the inner wall of the housing 4 The gap is 50mm. The distance between adjacent two-stage planar stencil packing groups is 900mm. The plane screens of the second and third plane screen packing groups are fixed on the outer wall of the central distribution tank by welding. There are 4 inside the sink groove Titanium diversion steel pipe. In the second-level sink groove and the third-level sink groove, there are 4 The connecting pipe made of titanium is connected to the sump and the outside of the rotating bed. The absorption liquid is introduced from the outside through the second-stage connecting pipe to supplement the intermediate absorption liquid and enter the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com