Construction method for controlling cleanliness of electronic-grade multicrystal-silicon process pipe

A technology for process pipelines and construction methods, applied in cleaning methods and utensils, chemical instruments and methods, circuits, etc., can solve the problems of difficult control of pipeline cleanliness and poor cleanliness control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

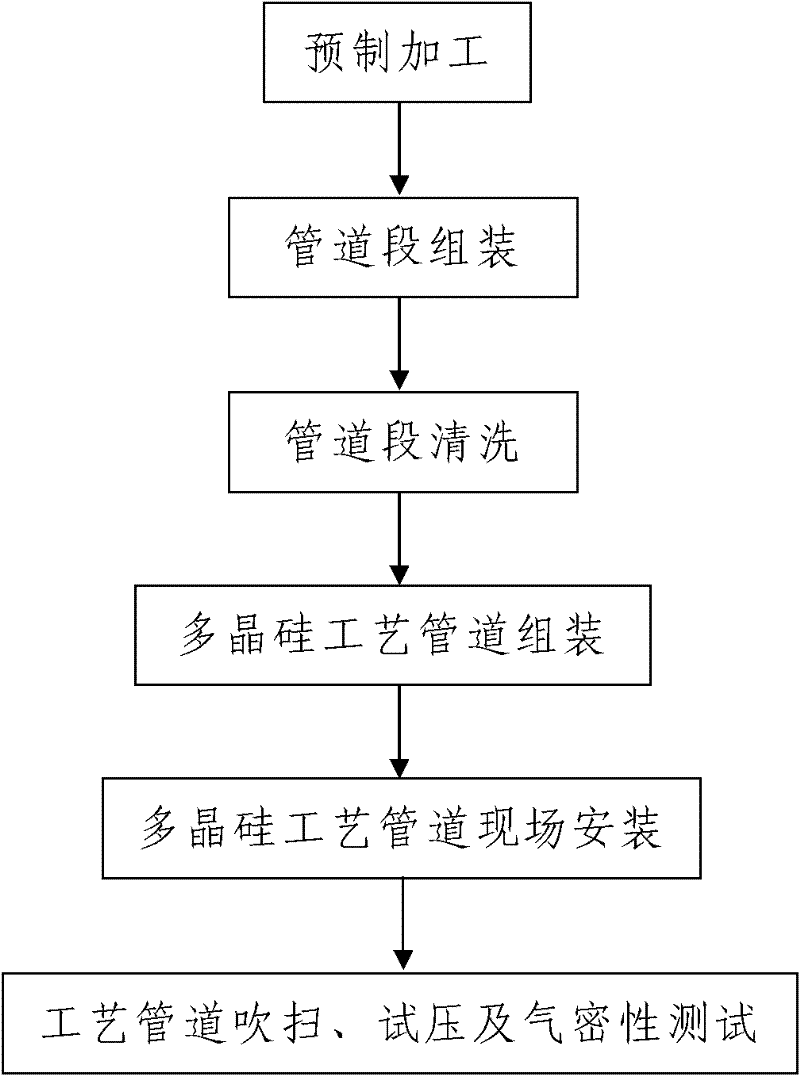

[0071] In this embodiment, the constructed polysilicon process pipeline is composed of multiple pipeline sections assembled, and two adjacent pipeline sections are connected by welding or through flanges; the pipeline section is an integral The pipeline segment may be assembled from multiple pipeline segments, and two adjacent pipeline segments in the pipeline segment are connected by welding or through flanges. like figure 1 As shown, the cleanliness control construction method of the polysilicon process pipeline comprises the following steps:

[0072] Step 1. Prefabrication processing: According to the pre-designed pipe section diagram and according to the conventional prefabrication method, assemble all the pipeline segments forming the polysilicon process pipeline, all the valves installed on the polysilicon process pipeline and the polysilicon process pipeline. All flanges required are prefabricated.

[0073] During the actual prefabrication process of all pipeline segm...

Embodiment 2

[0157] In this embodiment, the difference from Embodiment 1 is: when cutting the prefabricated parts of each pipeline segment in step 1, a machining allowance of 5 mm is reserved at the free end of the prefabricated parts of each pipeline segment; The angle of the V-shaped groove is 50°; in the internal gas protection device described in step 202, the lateral width of the exhaust cylinder is 20 cm, and when the welded joints are aligned for the two pipe segments to be welded , the gap between the welding port groups is 2.5mm; in step 204, after the argon gas is continuously introduced into step 203 for 4 minutes, the two welded pipe segments are welded by an argon arc welding machine; in step 2041, the tack welding process 4 solder joints are formed in , and the welding length of each solder joint is 5mm; Start welding after 20 mm from the starting welding position; in step 2043, seal welding is performed 5 minutes after the bottom welding described in step 2042; Introduce ar...

Embodiment 3

[0160] In this embodiment, the difference from Embodiment 1 is: when cutting the prefabricated parts of each pipeline segment in step 1, a machining allowance of 10 mm is reserved at the free end of the prefabricated parts of each pipeline segment; The angle of the V-shaped groove is 60°; in the internal gas protection device described in step 202, the lateral width of the exhaust cylinder is 50 cm, and the welded joints of the two pipe segments to be welded are aligned , the gap between the welding port groups is 3mm; in step 204, after the argon gas is continuously introduced into step 203 for 7 minutes, the two welded pipe segments are welded by an argon arc welding machine; in step 2041, during the tack welding process Form 3 welding spots, and the welding length of each welding spot is 10mm; in step 2042, after the positioning spot welding described in step 2041 is finished 6 minutes, carry out back welding, and when performing back welding, start from the scheduled time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com