Copper-based powder metallurgy thrust ring and preparation method thereof

A powder metallurgy and thrust ring technology is applied in the field of copper-based powder metallurgy thrust rings and their preparation, and can solve the problems of high molding pressure, high manufacturing cost, and complex thrust ring manufacturing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

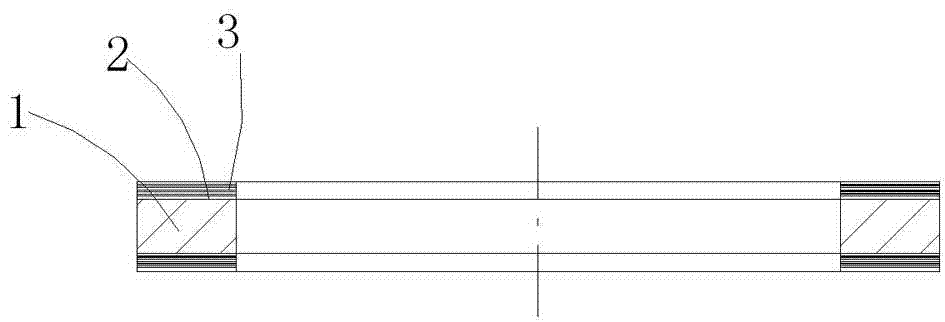

[0033] Such as figure 1 As shown, a copper-based powder metallurgy thrust ring, the copper core plate 1 is sprayed with tin bronze powder Sn6-6-3 as the bonding layer 2, and the bonding layer 2 is composited with copper-based powder metallurgy Friction layer 3; the copper-based powder metallurgy anti-friction layer 3 is formed by fully mixing 8% tin powder, 2% lead powder, 1% graphite powder and the rest copper powder. The thickness of the tin bronze powder bonding layer is 0.07mm. The thickness of the finished copper-based powder metallurgy anti-friction layer 3 is 0.4mm.

[0034] A method for preparing a copper-based powder metallurgy thrust ring, comprising the following steps:

[0035] (1) Copper plating layer: Copper plating is carried out on the surface of the stamped steel core plate after derusting and degreasing, and the thickness of the plating layer is 0.01mm;

[0036] (2), Coating adhesive layer and composite copper-based powder metallurgy anti-friction ...

Embodiment 2

[0045] Example 2: as figure 1 As shown, a copper-based powder metallurgy thrust ring, the copper core plate 1 is sprayed with tin bronze powder Sn6-6-3 as the bonding layer 2, and the bonding layer 2 is composited with copper-based powder metallurgy Friction layer 3; the copper-based powder metallurgy anti-friction layer 3 is formed by fully mixing 9% tin powder, 3% lead powder, 1% graphite powder and the rest copper powder. The thickness of the tin bronze powder bonding layer is 0.08mm. The thickness of the finished copper-based powder metallurgy anti-friction layer 3 is 0.5mm.

[0046] A method for preparing a copper-based powder metallurgy thrust ring, comprising the following steps:

[0047] (1) Copper plating layer: Copper plating is carried out on the surface of the stamped steel core plate after derusting and degreasing, and the thickness of the plating layer is 0.013mm;

[0048] (2), Coating adhesive layer and composite copper-based powder metallurgy anti-frict...

Embodiment 3

[0057] Example 3: as figure 1 As shown, a copper-based powder metallurgy thrust ring, the copper core plate 1 is sprayed with tin bronze powder Sn6-6-3 as the bonding layer 2, and the bonding layer 2 is composited with copper-based powder metallurgy Friction layer 3; the copper-based powder metallurgy anti-friction layer 3 is formed by fully mixing 10% tin powder, 4% lead powder, 1% graphite powder and the rest copper powder. The thickness of the tin bronze powder bonding layer is 0.10 mm. The thickness of the finished copper-based powder metallurgy anti-friction layer 3 is 0.6mm.

[0058] A method for preparing a copper-based powder metallurgy thrust ring, comprising the following steps:

[0059] (1) Copper plating layer: Copper plating is carried out on the surface of the stamped steel core plate after derusting and degreasing, and the thickness of the plating layer is 0.015mm;

[0060] (2), Coating adhesive layer and composite copper-based powder metallurgy anti-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com