Cobalt-containing nickel plated steel strip serving as lithium battery shell material and preparation method thereof

A shell material, lithium battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as implementation difficulties, and achieve the effects of reducing coating porosity, improving internal stress distribution, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

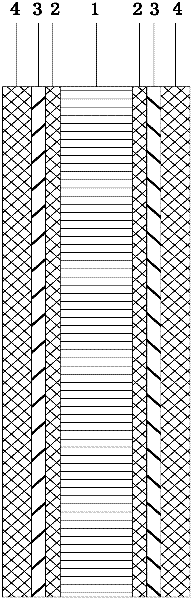

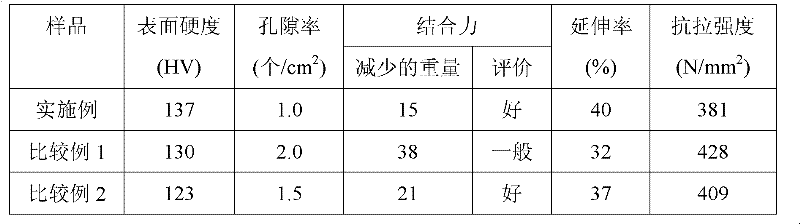

[0051] The present invention is used as lithium battery housing material cobalt-containing nickel-plated steel strip and its preparation method. SPCE is used as the base 1, and nickel-cobalt binary alloy films are respectively plated on both sides of the base 1; the nickel-cobalt binary The alloy film 2 is a nanocrystalline coating with a grain size of 50-100nm and a thickness of 2μm; the middle layer 3 is a Ni / Co / Fe diffusion layer with a thickness of 1μm produced after diffusion heat treatment; the surface layer 4 is a grain size of 50-100nm , a nickel-cobalt binary alloy film with a thickness of 2 μm. Such as figure 1 shown.

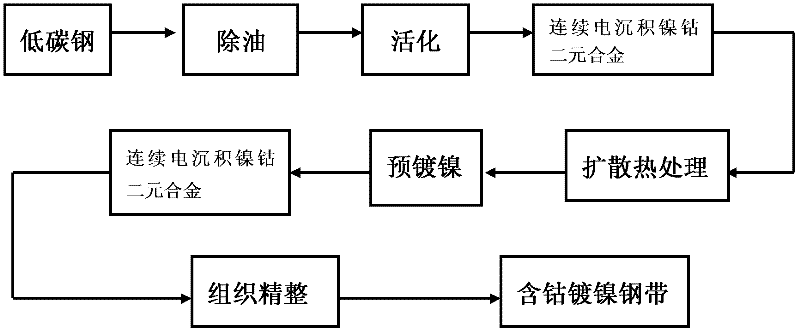

[0052] Technical process of the present invention sees figure 2 .

[0053] The special steel strip for SPCE batteries with a thickness of 0.3mm produced by a Japanese company is selected as the electroplating substrate.

[0054] Its chemical composition content is: C: ≤0.08 (% means weight percentage, the same below)

[0055] S...

Embodiment 2

[0103] Embodiment 2 coating thickness design and process flow are the same as embodiment 1.

[0104] The coating thickness of the present invention is designed as figure 1 shown.

[0105] Technical process of the present invention sees figure 2 .

[0106] 1. Surface pretreatment before plating

[0107] First put the substrate into the degreasing solution for electrochemical degreasing, then rinse the degreased substrate surface with distilled water, and then put it into the activator for activation;

[0108] The degreasing fluid is:

[0109] Degreasing fluid temperature: 80°C

[0110] Degreasing time: 3min

[0111] After the degreasing is complete, rinse the surface of the sample with distilled water, and then put it into the activator for activation.

[0112] Activator composition: 3vol% HCl

[0113] Activation time: 1.5min.

[0114] 2. Continuous electrodeposited nickel-cobalt alloy coating with a grain size of 50-100nm

[0115] Plating solution composition:

...

Embodiment 3

[0149] Embodiment 3 coating thickness design and process flow are the same as embodiment 1.

[0150] The coating thickness of the present invention is designed as figure 1 shown.

[0151] Technical process of the present invention sees figure 2 .

[0152] 1. Surface pretreatment before plating

[0153] First put the substrate into the degreasing solution for electrochemical degreasing, then rinse the degreased substrate surface with distilled water, and then put it into the activator for activation;

[0154] The degreasing fluid is:

[0155] Degreasing fluid temperature: 80°C

[0156] Degreasing time: 3min

[0157] After the degreasing is complete, rinse the surface of the sample with distilled water, and then put it into the activator for activation.

[0158] Activator composition: 3vol% HCl

[0159] Activation time: 1.5min.

[0160] 2. Continuous electrodeposited nickel-cobalt alloy coating with a grain size of 50-100nm

[0161] Plating solution composition: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com