Carbon nano tube (CNT)/ polylactic acid (PLA) composite material and preparation method thereof

A technology of carbon nanotubes and composite materials, which is applied in the preparation of plasticizer-assisted dispersion of carbon nanotubes, and in the field of carbon nanotube/polylactic acid composite materials, can solve the problems of long operation process and complicated CNT process, and achieve high performance improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

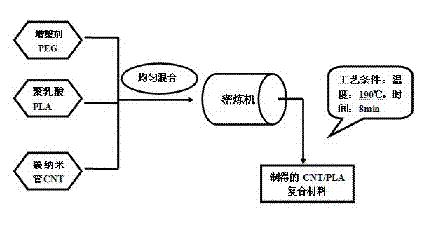

[0020] Example 1: The weights of polylactic acid, polyethylene glycol, and carbon nanotubes are 63g, 7g, and 2.1g, respectively. After weighing, the three materials were directly poured into the internal mixer for internal mixing, and the composite material was prepared by a general melt blending process, the process temperature was set at 190°C, and the time was 8 minutes. Before use, treat the carbon nanotubes, put the carbon nanotubes into KMnO 4 、H 2 SO 4 and H 3 PO 4 mixed acid solution, where KMnO 4 Mass ratio 0.3%, H 2 SO 4 and H 3 PO 4 The volume ratio is 2:1, ultrasonic for 40min, and then washed repeatedly in distilled water to remove acid and impurities.

Embodiment 2

[0021] Example 2: The weights of polylactic acid, polyethylene glycol, and carbon nanotubes are 66g, 4g, and 1.05g, respectively. After weighing, the three materials were directly poured into the internal mixer for internal mixing, and the composite material was prepared by a general melt blending process, the process temperature was set at 190°C, and the time was 8 minutes. The treatment of carbon nanotubes is as in Example 1.

Embodiment 3

[0022] Embodiment 3: The weights of polylactic acid, polyethylene glycol, and carbon nanotubes are 56g, 14g, and 3.5g, respectively. After weighing, the three materials were directly poured into the internal mixer for internal mixing, and the composite material was prepared by a general melt blending process. The process temperature was set at 180°C and the time was 8 minutes. The treatment of carbon nanotubes is as in Example 1.

[0023] The composite material is composed of carbon nanotubes, polyethylene glycol and polylactic acid, wherein the weight of polyethylene glycol is 5%-20% of the total weight, and the weight of carbon nanotubes is 1.5% of the total weight of polyethylene glycol and polylactic acid —5%, the remainder is polylactic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com