Method and device for forming metal reducer pipe based on laser shock wave technology

A technology of variable diameter pipe and shock wave, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of pipe instability, difficulty in adapting, and rupture, and achieve simple and convenient operation, avoid hydraulic equipment, and delay decay Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

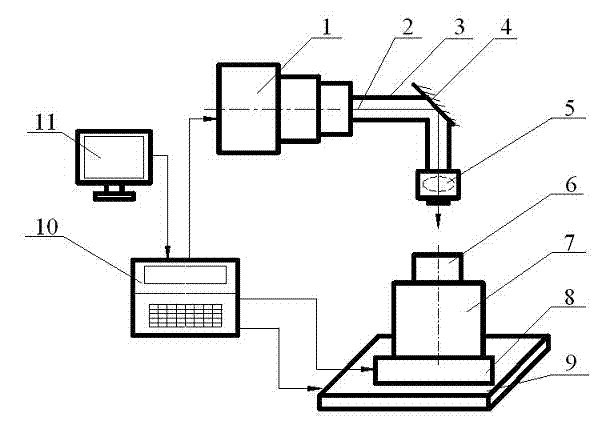

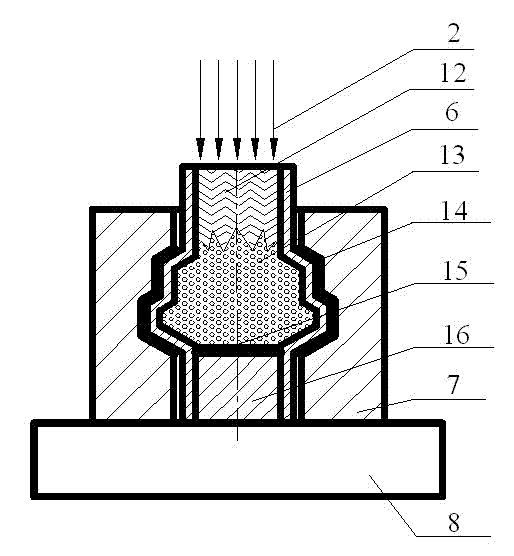

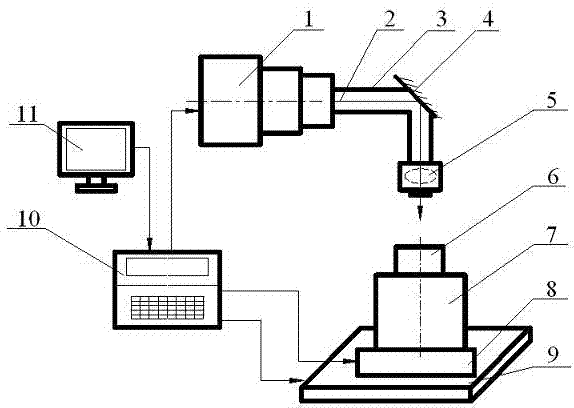

[0019] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The device mainly includes a laser generator 1, a light guide system, a workpiece fixture system and a control system. Wherein the light guide system includes a light guide pipe 3 , a total reflection mirror 4 and an impact head 5 . The workpiece fixture system consists of a metal reducer tube blank 6, a protective pad 14, a split mold 7, a constraining layer (water) 12, an absorption layer (black paint) 15, a blocking rod 16, a bracket 8, and a workbench 9. The control system includes a computer 11 and a controller 10 .

[0021] The laser generator 1 emits an optimized laser pulse beam 2 , the beam mode of the laser pulse beam 2 can be multiple modes such as fundamental mode and multi-mode, which are regulated and controlled by the controller 10 . The laser pulse beam 2 emitted by the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com