Brush-coat type phosphating solution containing rust and preparation method thereof

A phosphating solution, with rust technology, applied in the field of phosphating solution, can solve the problems of not being able to adapt to new situations, long phosphating time, complicated procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

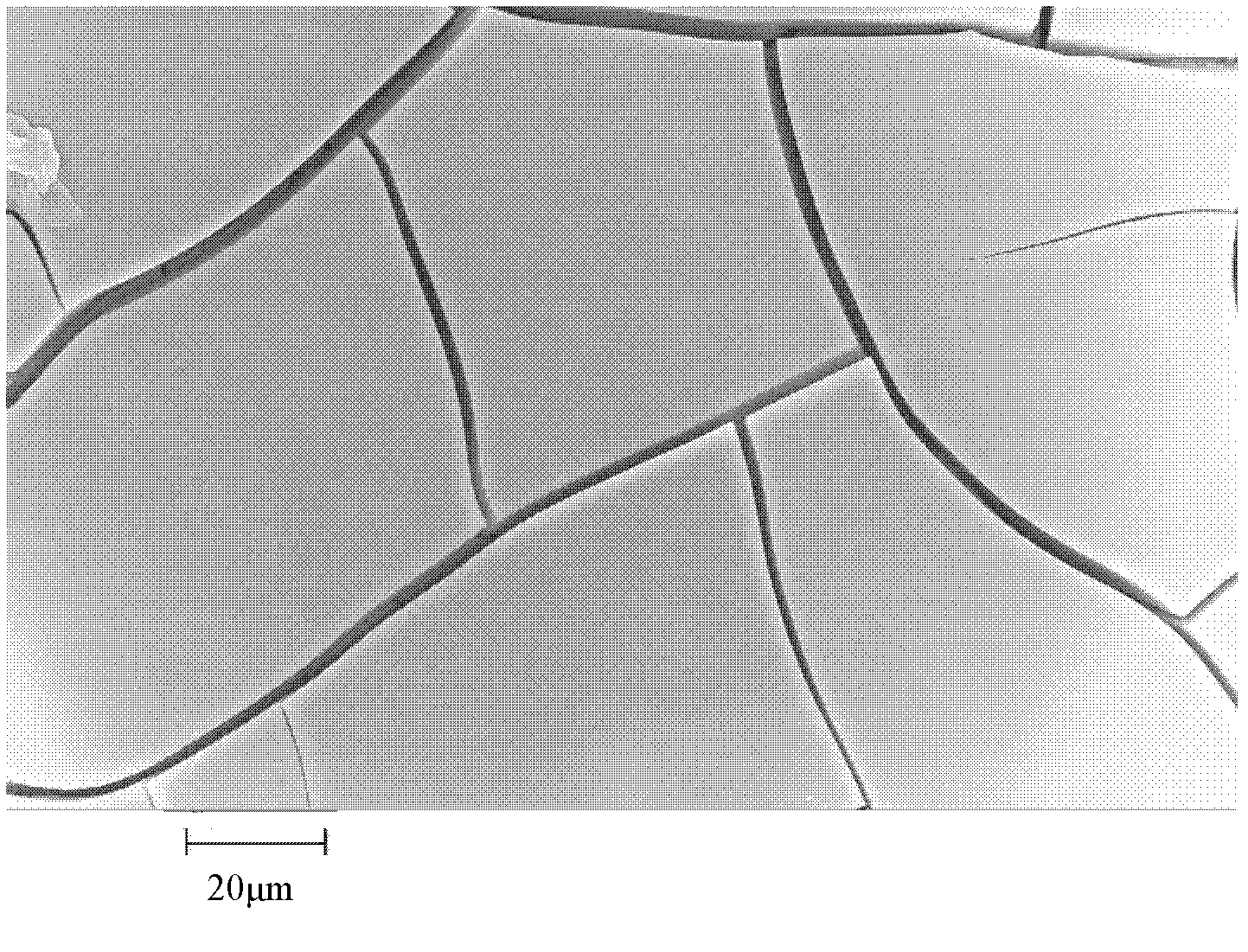

Image

Examples

Embodiment 1

[0027] The brushing type rusty phosphating solution of the present invention is made up of following raw material:

[0028] Phosphoric acid 174mL / L;

[0030] EDTA 6g / L;

[0031] Ethanol 126.6mL / L;

[0032] Sodium molybdate 1.5g / L;

[0033] Sodium fluoride 1g / L;

[0035] Polyethylene glycol 6000 2g / L;

[0036] water balance.

[0037] Add zinc oxide into a small amount of water to make a paste, then add phosphoric acid and stir until fully dissolved. Add EDTA and stir until fully dissolved. Then add ethanol, sodium molybdate, nickel sulfate, polyethylene glycol 6000 in turn, stir evenly, and finally add enough water. The iron door with serious rust is treated by brushing, the film forming effect is good, the film layer is bright black, and the paint film has good adhesion.

Embodiment 2

[0039] The brushing type rusty phosphating solution of the present invention is made up of following raw material:

[0040] Phosphoric acid 208.8mL / L;

[0041] Zinc oxide 1g / L;

[0042] EDTA 10g / L;

[0043] Ethanol 126.6mL / L;

[0044] Sodium molybdate 2.5g / L;

[0045] Sodium fluoride 3g / L;

[0046] Nickel sulfate 1.5g / L;

[0047] Polyethylene glycol 6000 4g / L;

[0048] water balance.

[0049] The preparation method of phosphating solution is the same as in Example 1. It is operated by brushing to deal with the iron ship hull with serious rust, the effect is good, the film layer is bright black, and the bonding force is strong.

Embodiment 3

[0051] The brushing type rusty phosphating solution of the present invention is made up of following raw material:

[0052] Phosphoric acid 139.2mL / L;

[0053] Zinc oxide 3g / L;

[0054] EDTA 4g / L;

[0055] Ethanol 126.6mL / L;

[0056] Sodium molybdate 2g / L;

[0057] Sodium fluoride 1.5g / L;

[0058] Nickel acetate 2g / L;

[0059] Polyethylene glycol 6000 3g / L;

[0060] water balance.

[0061] The preparation method of phosphating solution is the same as in Example 1. It is operated by brushing to deal with the iron bracket with serious rust. The effect is good, the film layer is bright and black, and the bonding force is strong.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com