Method and device for purifying zinc sulfate solution based on action of cavitation effect

A technology of zinc sulfate solution and cavitation effect, applied in the direction of improving process efficiency, etc., can solve the problems of large zinc powder consumption, environmental pollution, high energy consumption, etc., and achieve reduced zinc powder unit consumption, low impurity content, and process flow shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

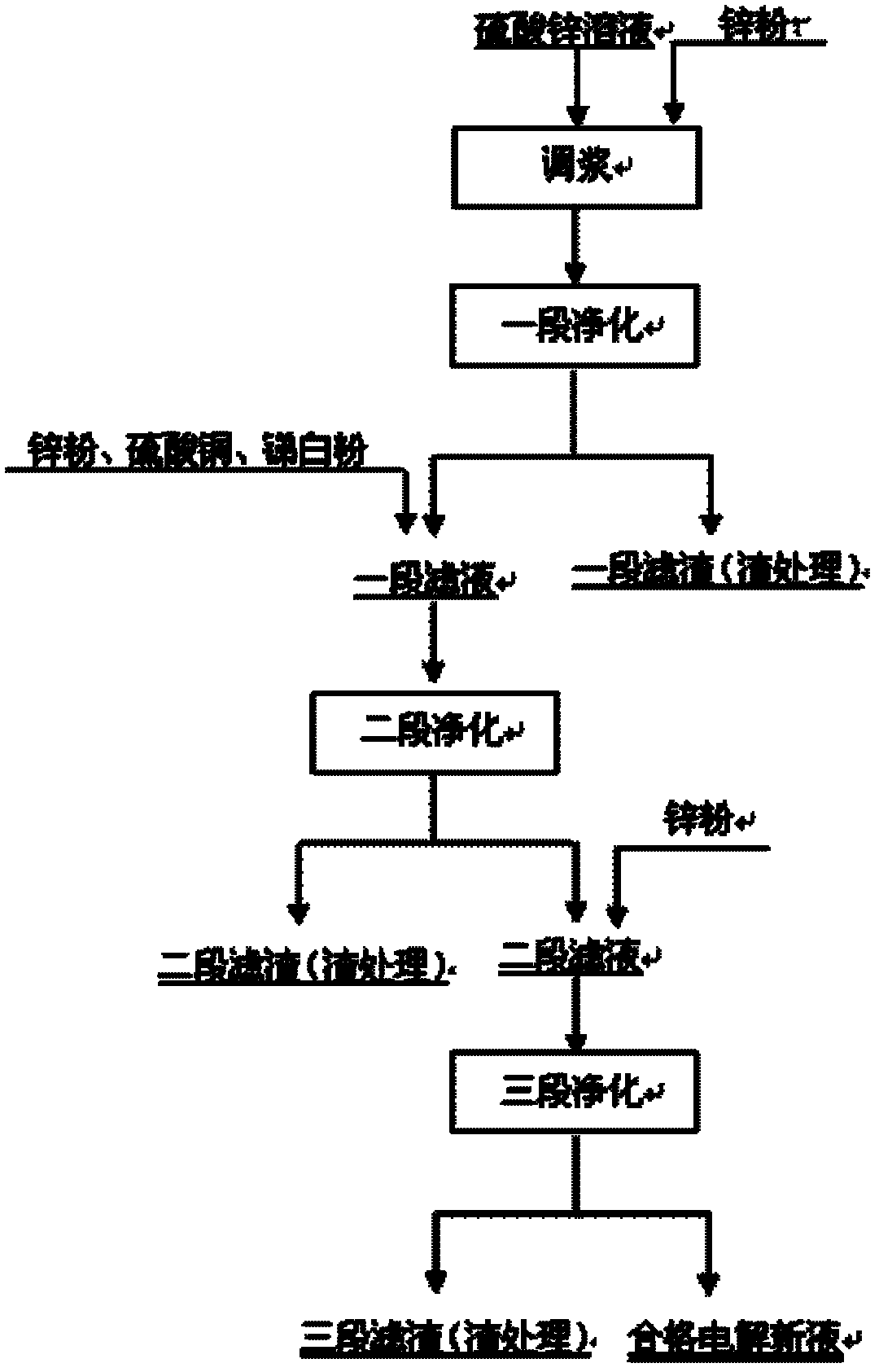

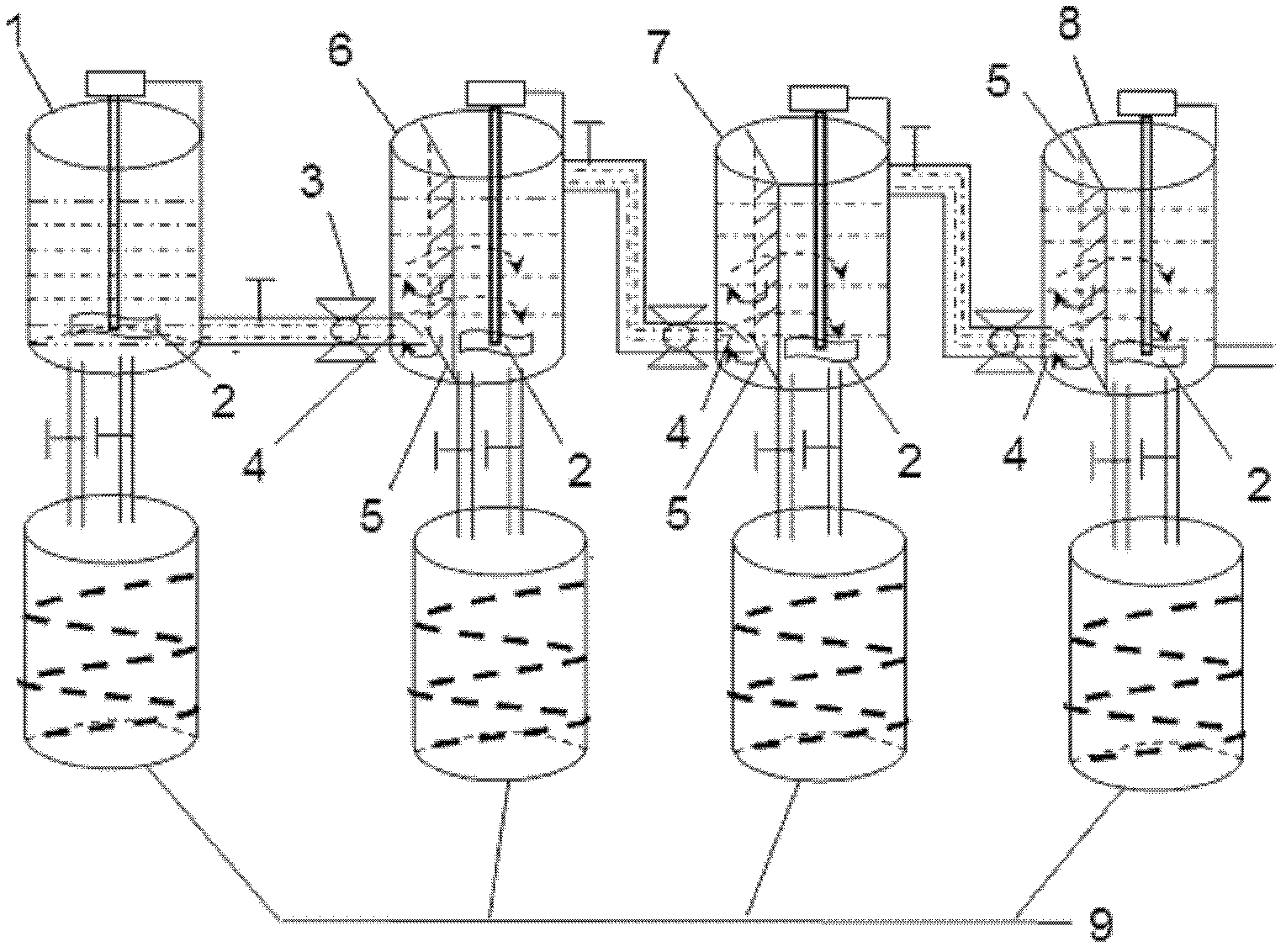

[0057] Example 1: Pre-purification solution of zinc sulfate containing impurities of cadmium, cobalt, nickel, and copper. The impurity content range is: Cd642.48mg / L, Cu18.33mg / L, Ni23.96mg / L, Co32.05mg / L. The purification process with three-stage cavitation effect produces qualified new electrolyte, such as image 3 Shown.

[0058] Firstly, heat the zinc sulfate solution to 55~85℃ through the heat exchanger 9, and the zinc powder is added to the slurry tank 1 in a conventional manner to adjust the slurry with the zinc sulfate solution at 1.0 to 1.4 times the Cu+Cd impurity content in the zinc sulfate solution. , And then use the transfer pump 3 to inject the zinc sulfate solution into a purification tank 6 through a spray gun 4. The partition 5 in the tank prevents the fierce reflux effect and forms cavitation bubbles, which react in the purification tank. The time is 10 minutes. Delivery pump pressure is 3.8~4.5MPa, delivery pump flow rate is 6.0m 3 / h; The filtrate enters the...

Embodiment 2

[0062] Example 2: A zinc sulfate solution before purification containing impurities of cadmium, cobalt, nickel, and copper. The impurity content range is: Cd454.55mg / L, Cu162.5mg / L, Ni12.5mg / L, Co37.5mg / L. The purification process with two stages of cavitation effect produces qualified new electrolyte solution, and zinc powder is added in the form of slurry. Such as image 3 Shown.

[0063] First, heat the zinc sulfate solution to 55-85°C through the heat exchanger 9. The zinc powder is added to the slurry tank 1 in a conventional manner to adjust the slurry with the zinc sulfate solution at 1.0-1.4 times the Cu+Cd impurity content in the solution, and then The transfer pump 3 is used to inject the zinc sulfate solution after mixing into a purification tank 6 through a spray gun 4 for purification. One stage of purification process is the process of removing copper and cadmium, and the temperature is 55-85°C; the first stage of purification tank has no partitions, and the reacti...

Embodiment 3

[0067] Example 3: The pre-purification solution of zinc sulfate containing impurities of cadmium, cobalt, nickel, and copper. The impurity content range is: Cd636.36mg / L, Cu62.5mg / L, Ni14.02mg / L, and Co58mg / L. A two-stage purification process is adopted to produce qualified new electrolyte. Such as Figure 4 Shown.

[0068] First, heat the zinc sulfate purification solution to 55-85℃ through the heat exchanger 9. The zinc powder is added to the slurry tank 1 at 1.0-1.4 times the Cu+Cd impurity content and 20-40 times the Co+Ni content in the solution. Adjust the slurry with zinc sulfate solution, and add it in a conventional way. After high-speed stirring by the propeller blade stirring device 2 in tank 1, the zinc sulfate solution after mixing is fed into a purification tank 6 by the conveying pump 3, and the propeller blade in tank 2 After the high-speed stirring of the stirring device 2 and the baffle 5, a vortex is generated. The reaction time is 20 minutes. A purification p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com