Filtrate reducer for oil well cement and preparation method thereof

A fluid loss reducing agent, oil well cement technology, applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problems of inconvenient long-distance transportation, unstable properties, and high equipment costs, and achieve long-term storage and long-distance transportation. The effect of fast dissolution speed and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

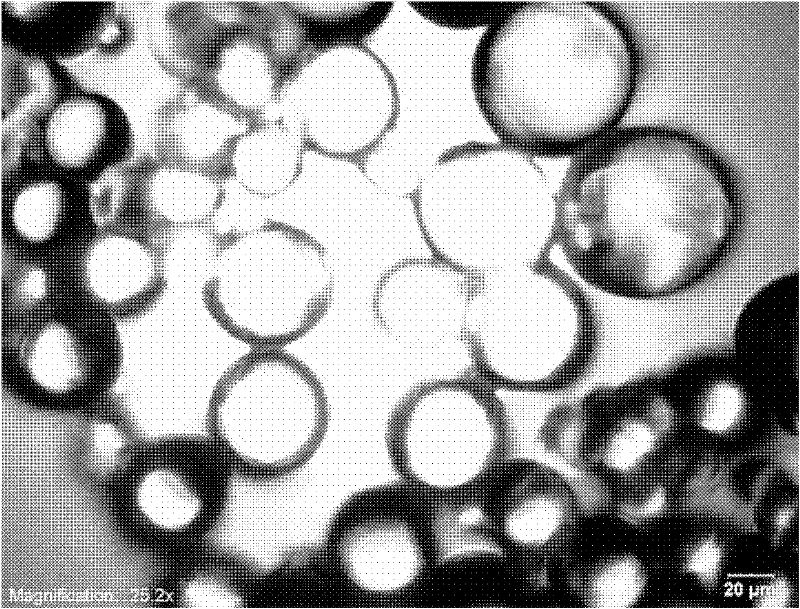

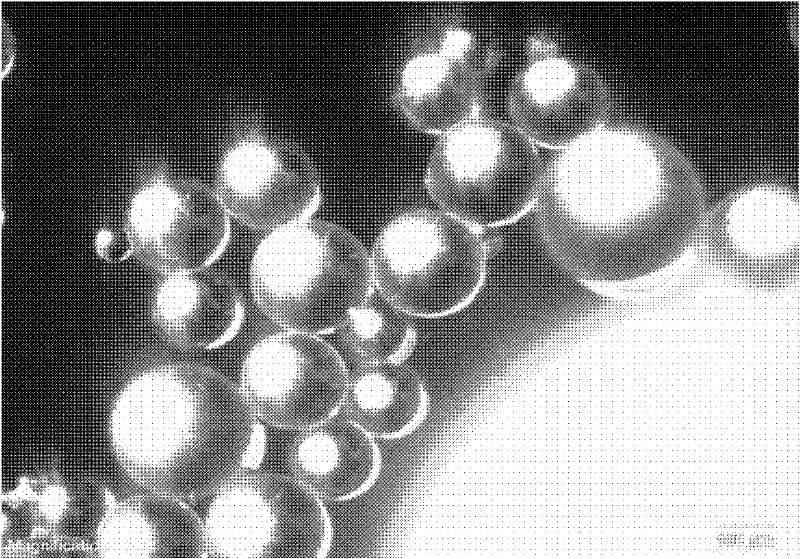

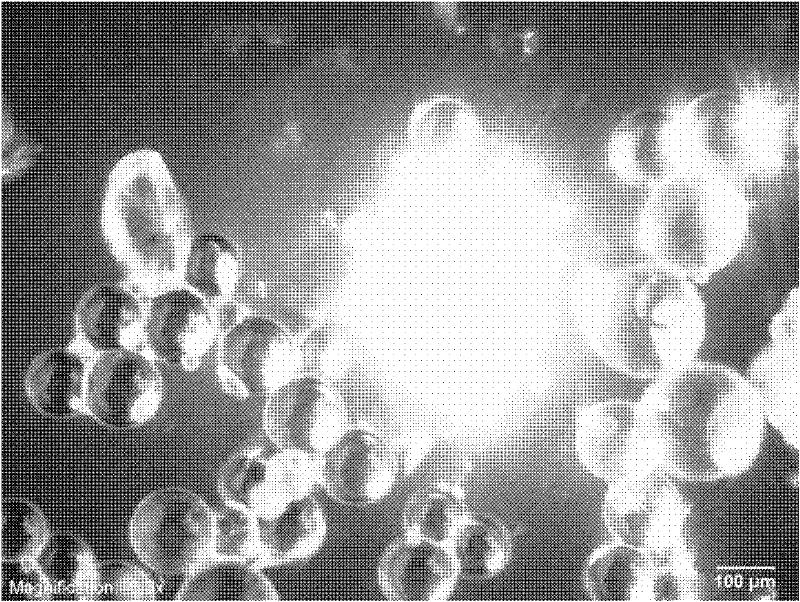

Image

Examples

Embodiment 1

[0029] Add 1.05 g of sorbitan monostearate and 150 mL of cyclohexane into a 250 mL four-neck flask, heat to 50° C. and stir to dissolve sorbitan monostearate, then cool for use. Nitrogen was introduced for about 30 minutes, 5.49g NaOH was added into the beaker, dissolved in 10mL distilled water to obtain NaOH solution, cooled at room temperature for use. Add 25.844 g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 2.975 g of N,N-dimethylacrylamide (NNDMA), and 0.602 g of maleic anhydride into a beaker and dissolve completely with 20 mL of distilled water Monomer solution was obtained. Place the monomer solution in an ice-water bath, slowly add the prepared NaOH solution dropwise therein, stir to mix evenly to obtain the prepared monomer solution, slowly drop it into a four-neck flask, and start heating to raise the temperature. When the temperature rose to 55°C, 0.149 g of ammonium persulfate solution was added. After a while, the reaction self-heated. After the end of...

Embodiment 2

[0031] Add 1.05 g of sorbitan monostearate and 150 mL of cyclohexane into a 250 mL four-neck flask, heat to 50° C. and stir to dissolve sorbitan monostearate, then cool for use. Nitrogen was introduced for about 30 minutes, 5.5g NaOH was added into the beaker, dissolved in 10mL distilled water to obtain NaOH solution, cooled at room temperature for later use. Add 25.844g of 2-acrylamido-2-methylpropanesulfonic acid, 2.8g of N,N-diethylacrylamide and 0.602g of fumaric acid into a beaker, and completely dissolve with 20mL of distilled water to obtain a monomer solution. Put the monomer solution in an ice-water bath, slowly add NaOH solution dropwise therein, stir to mix evenly to obtain a prepared monomer solution, drop slowly into a four-neck flask, and start heating to raise the temperature. When the temperature rose to 55°C, 0.149 g of ammonium persulfate solution was added. After a while, the reaction self-heated. After the end of the temperature rise, the temperature was ...

Embodiment 3

[0033]Add 1.05 g of sorbitan monostearate and 150 mL of cyclohexane into a 250 mL four-neck flask, heat to 50° C. and stir to dissolve sorbitan monostearate, then cool for use. Nitrogen was introduced for about 30 minutes, 5.49g NaOH was added into the beaker, dissolved in 10mL distilled water to obtain NaOH solution, cooled at room temperature for use. Add 25.9g of methacrylic acid, 2.9g of N,N-diethylacrylamide and 0.6g of fumaric acid into a beaker, and completely dissolve with 20mL of distilled water to obtain a monomer solution. Put the monomer solution in an ice-water bath, slowly add NaOH solution dropwise therein, stir to mix evenly to obtain a prepared monomer solution, drop slowly into a four-neck flask, and start heating to raise the temperature. When the temperature rose to 55°C, 0.149 g of ammonium persulfate solution was added. After a while, the reaction self-heated. After the end of the temperature rise, the temperature was controlled between 65°C and 70°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com