Agricultural degradable stone paper and preparation method thereof

A kind of stone paper, Ruitai technology, applied in applications, household appliances, flat products, etc., can solve the problems of long degradation period, incomplete degradation effect, high cost, save labor costs, protect land resources, and improve farmland environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

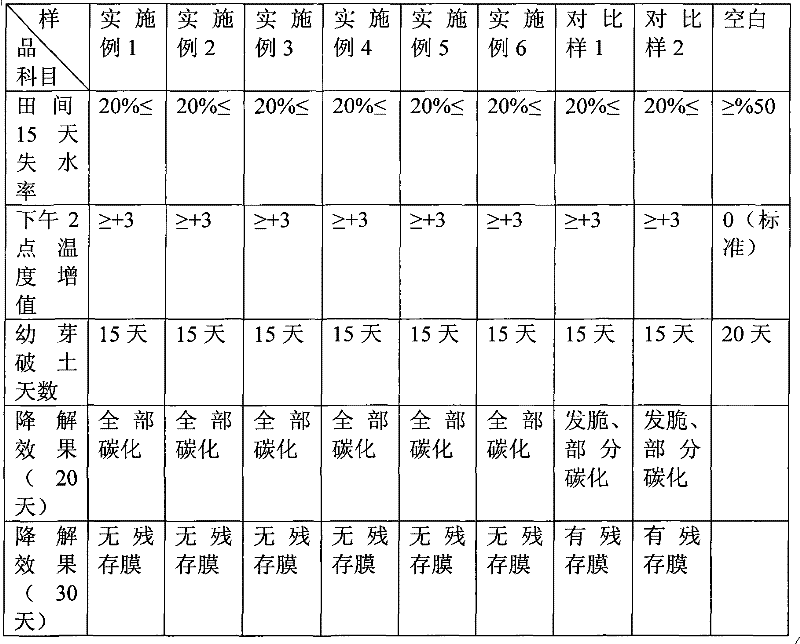

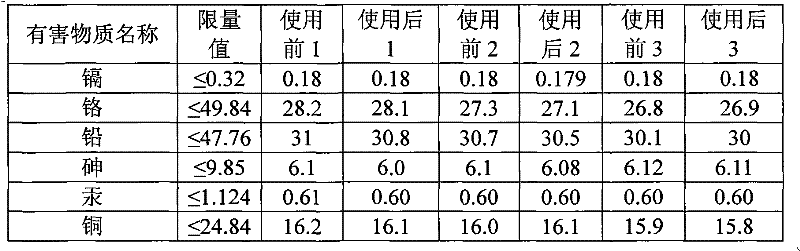

Examples

Embodiment 1

[0034] 1 part of rutile titanium dioxide, 3 parts of sharp titanium dioxide, 0.1 part of cobalt acetylacetonate, 0.3 part of photosensitive dye, 0.3 part of anhydrous ferric chloride, 65 parts of 2000 mesh heavy calcium carbonate, 1500 mesh light calcium carbonate 10 parts, 5 parts of silane coupling agent, 15 parts of low density polyethylene, 10 parts of 80 ℃ hot melt adhesive, 1.5 parts of stearic acid, 1.5 parts of epoxy soybean oil, 0.2 parts of polyethylene wax, 0.5 parts of bentonite, dehydration 0.5 parts of sorbitol stearate.

[0035] Preparation:

[0036] Mix rutile-type titanium dioxide and sharp-type titanium dioxide, mix cobalt acetylacetonate and photosensitizing dye, dissolve it in absolute ethanol at a ratio of 1:10 (weight ratio of cobalt acetylacetonate to ethanol), and spray it on the titanium dioxide, mix; add Anhydrous ferric chloride, mix evenly; add heavy and light calcium carbonate, then spray silane coupling agent and mix evenly, heat up to 120°C, mix...

Embodiment 2

[0038] 3 parts of rutile titanium dioxide, 1 part of sharp titanium dioxide, 0.15 parts of cobalt acetylacetonate, 0.6 parts of anhydrous ferric chloride, 60 parts of heavy calcium carbonate of 1900 mesh, 15 parts of light calcium carbonate of 1600 mesh, silane 4 parts of coupling agent, 25 parts of low-density polyethylene, 5 parts of hot melt adhesive at 85°C, 0.5 part of stearic acid, 0.5 part of epoxy soybean oil, 0.3 part of polyethylene wax, 1.5 parts of bentonite, dehydrated sorrel 0.7 parts of alcohol stearate.

[0039] Preparation:

[0040] Mix rutile-type titanium dioxide and sharp-type titanium dioxide, mix cobalt acetylacetonate and photosensitizing dye, dissolve it in absolute ethanol at a ratio of 1:10 (weight ratio of cobalt acetylacetonate to ethanol), and spray it on the titanium dioxide, mix; add Anhydrous ferric chloride, mix; add heavy and light calcium carbonate, then spray into silane coupling agent and mix evenly, heat up to 140°C, mix for 30 minutes, t...

Embodiment 3

[0042] 2.5 parts of rutile titanium dioxide, 1.5 parts of sharp titanium dioxide, 0.2 parts of cobalt acetylacetonate, 0.4 parts of anhydrous ferric chloride, 50 parts of heavy calcium carbonate of 1800 mesh, 25 parts of light calcium carbonate of 1700 mesh, silane 3 parts of joint agent, 20 parts of low-density polyethylene, 8 parts of 90°C hot melt adhesive, 1 part of stearic acid, 1 part of epoxy soybean oil, 0.4 parts of polyethylene wax, 1 part of bentonite, sorbitan stearic acid 0.6 part of ester.

[0043] Preparation:

[0044] Mix rutile-type titanium dioxide and sharp-type titanium dioxide, mix cobalt acetylacetonate and photosensitizing dye, dissolve it in absolute ethanol at a ratio of 1:10 (weight ratio of cobalt acetylacetonate to ethanol), and spray it on the titanium dioxide, and mix evenly; Add anhydrous ferric chloride and mix evenly; add heavy and light calcium carbonate, then spray silane coupling agent and mix evenly, heat up to 130°C, mix for 45 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com