Method for automatic check of process data of printed circuit board

A printed circuit board and data processing technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as low efficiency, difficulties, lack of communication bridges, etc., and achieve the effect of improving efficiency and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

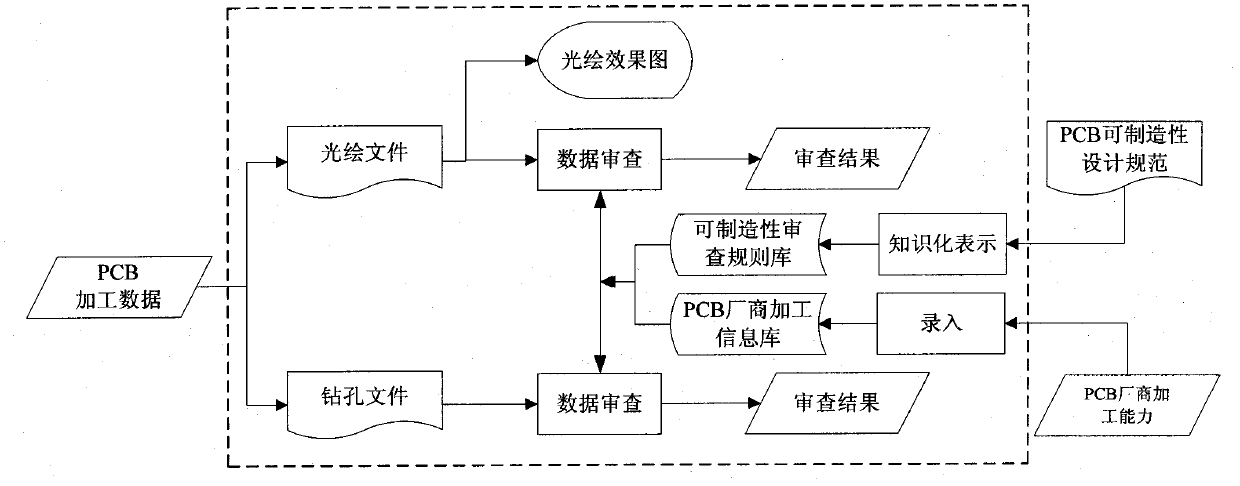

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0082] PCB processing data automatic review method is the same as embodiment 1

[0083] The inspection object of the present invention is the PCB manufacturing data file, which is a light drawing file and a drilling file that can be automatically exported by various electronic circuit design software, that is, a Gerber file and an NCDrill file. Gerber file is an international standard photo-painting format file, which includes RS-274-D and RS-274-X two formats, RS-274-D is called the basic Gerber format, and it must be accompanied by a D code file to Completely describe a graphic; RS-274-X is called the extended Gerber format, which itself contains D code information. Commonly used CAD software can generate files in both formats. The NCDrill file is a description of the drilling information in the same PCB design, and the format is the same as the Gerber file. For the two different formats RS-274-D and RS-274-X of the light painting file, the general data structure designed ...

Embodiment 3

[0086] The method for automatic inspection of PCB processing data is the same as in Embodiment 1-2

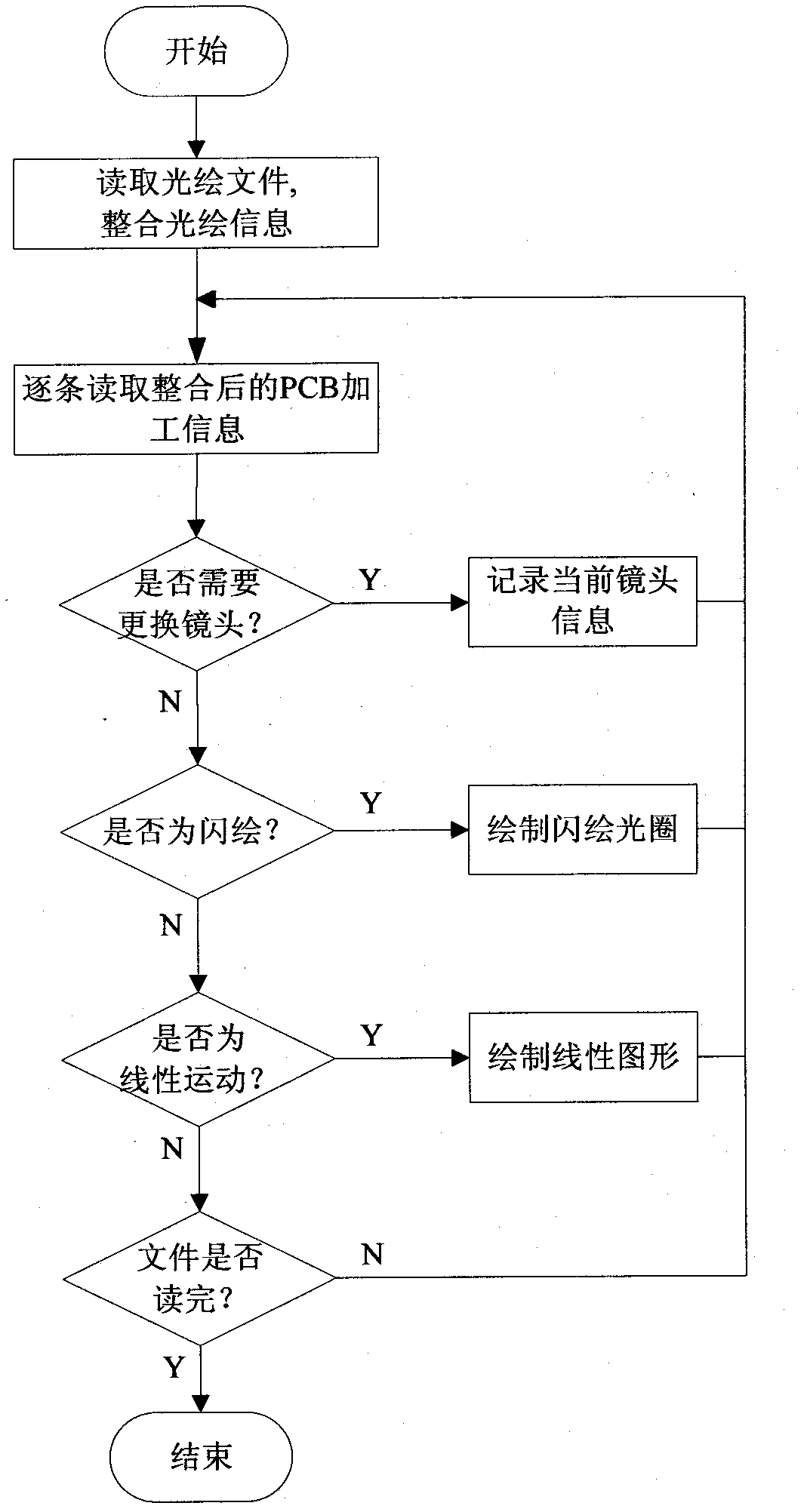

[0087] figure 2 It is a schematic diagram of the visualized flow chart of the PCB light-drawing file of the present invention. The invention can realize layered display of PCB light drawing files according to PCB design.

[0088] In the process of PCB light drawing, there are two main operation modes for the lens of the light plotter: linear motion and flash drawing. Among them, the linear movement in the PCB photopainting process is aimed at the wiring, silk screen and board frame in the PCB design, and the width of the line corresponds to the size of the aperture in the photopainting process. The invention can simulate the operation mode of the lens to draw the wiring in the PCB design , silk screen and board frame; and flash painting is aimed at the pads in PCB design. The diameter of the circular pad and the length and width of the rectangular pad correspond to the size ...

Embodiment 4

[0091] The method for automatic inspection of PCB processing data is the same as in Embodiment 1-3

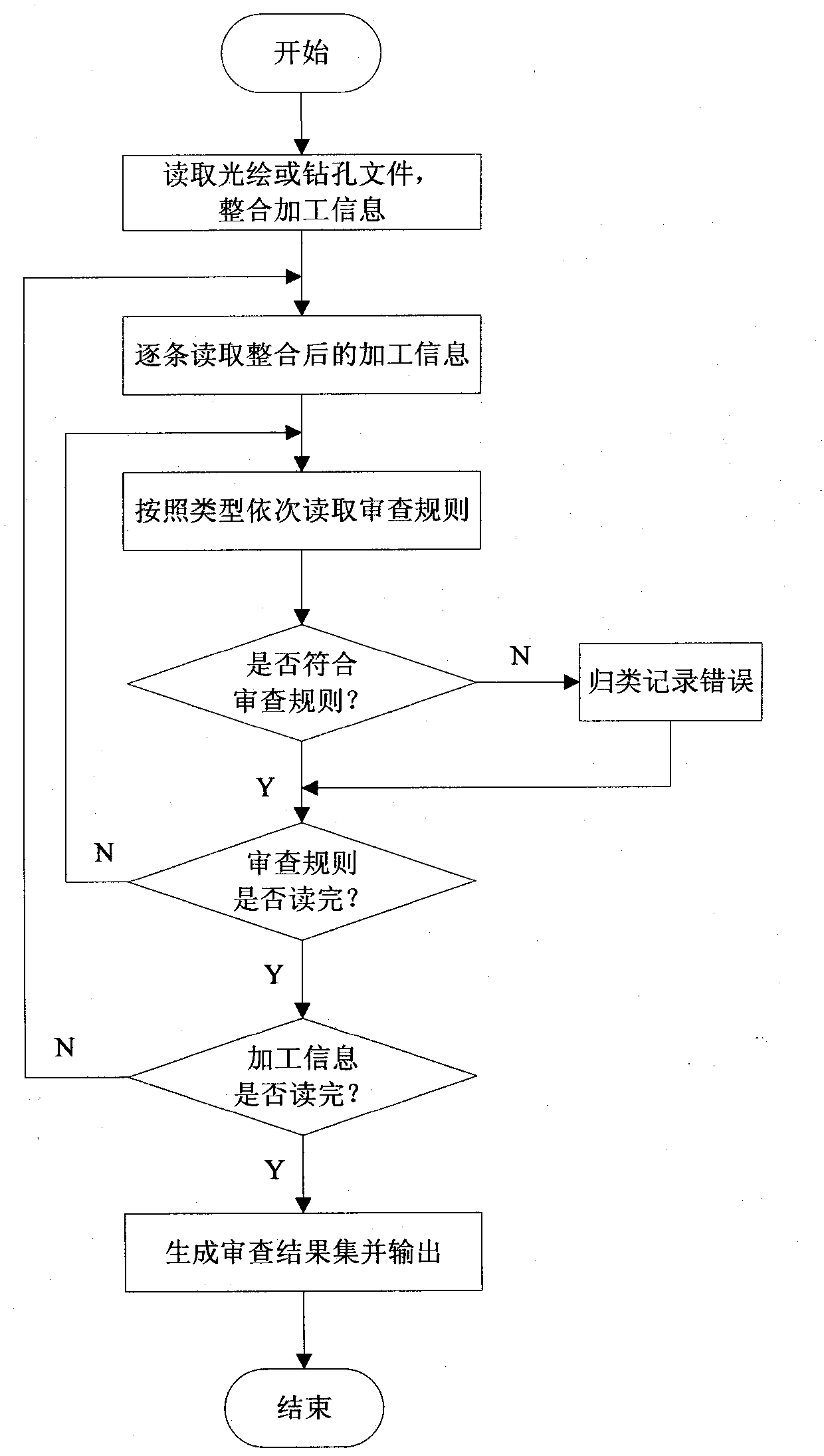

[0092] image 3 It is a schematic diagram of processing data review and result output flow in the present invention. The data review of drilling files is similar to that of gerber files, here we take the data review of gerber files as an example to illustrate.

[0093] The present invention firstly reads the light-painting file, and integrates the processing data in the file, reads the integrated light-painting processing information one by one, and then reads the rules in the review rule database according to the processing type of the currently read processing information, And review the processing data, if it does not meet the review rules, record this error, including error type, error location, error cause and other information, if it meets, continue to read the review rules until all the rules are read; after integration, each The processing information will cycle throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com