Separation method and devices of thermal dissolution and catalysis liquefied product of lignite

A technology for catalytic liquefaction and separation equipment, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of low total yield of liquefied oil, slow speed, and huge equipment, and achieve low cost, reduced energy consumption, and localization high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

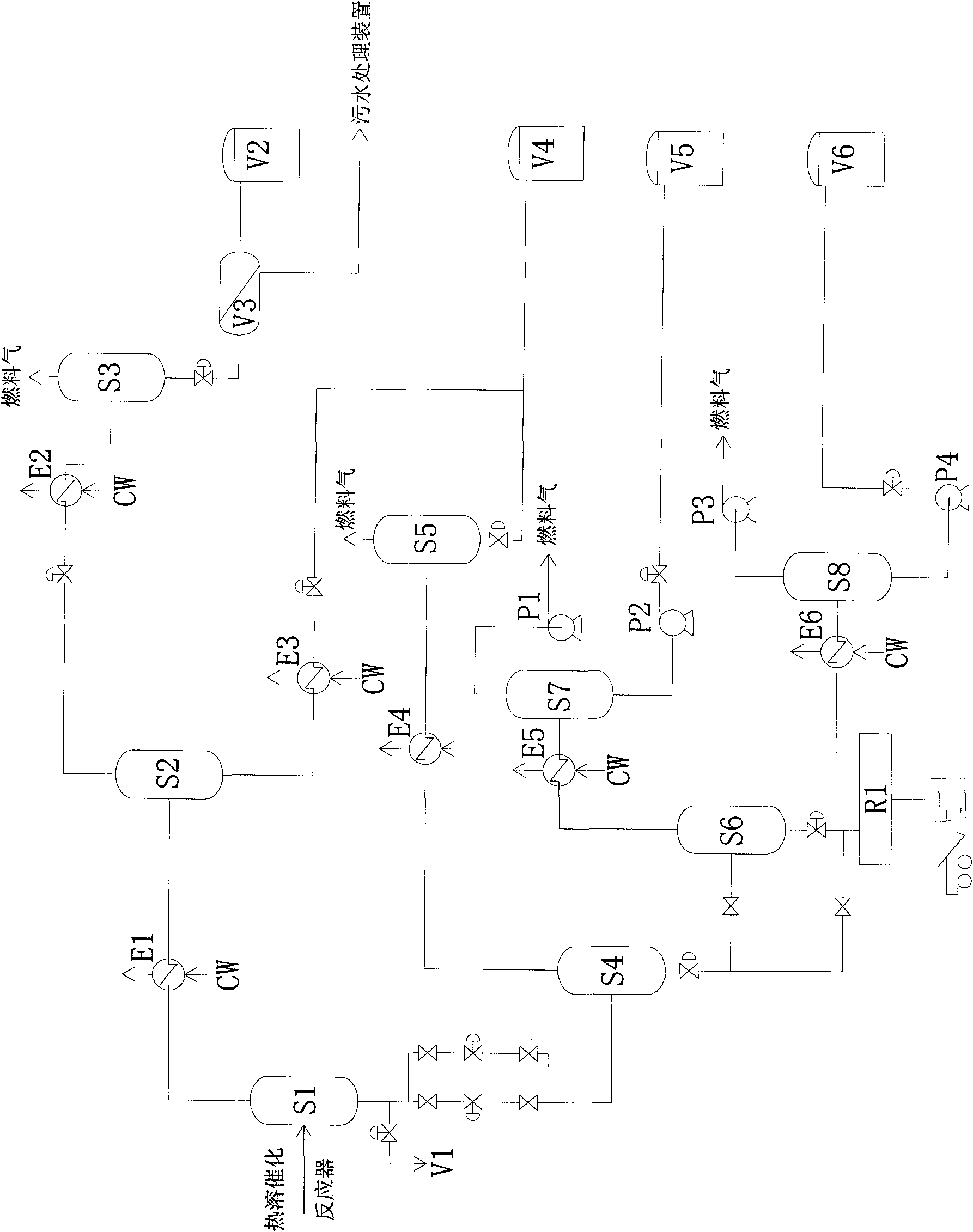

[0041] Such as figure 1 As shown, the separation equipment of lignite thermal-dissolution catalytic liquefaction product according to the present invention mainly includes high-temperature separator S1, which is connected with lignite thermal-dissolution catalytic reactor through pipeline; light oil separator S2, which is connected with high-temperature separator through pipeline The gas phase outlet of S1 is connected, and a high-temperature separation cooler E1 is provided on the pipeline; the gas-oil separator S3 is connected with the gas phase outlet of the light oil separator S2 through a pipeline, and a low-temperature cooler E2 is provided on the pipeline; Analyzer V3 is connected to the liquid phase outlet of gas-oil separator S3 through pipelines; V2 light oil storage tank is connected to the oil phase outlet of decanter V3 through pipelines; medium oil storage tank V4 is connected to light oil storage tank through pipelines The liquid phase outlet of the separator S2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com