Method for plating metal layer by virtue of ionodialysis chemistry

A dialysis chemical and metal plating technology, which is applied in the field of ion dialysis chemical plating metal layer, can solve the problems of difficult processing and short service life of the plating solution, and achieve the effects of improving the quality of the plating layer, maintaining process stability, and simplifying preparation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment one ion dialysis electroless nickel plating

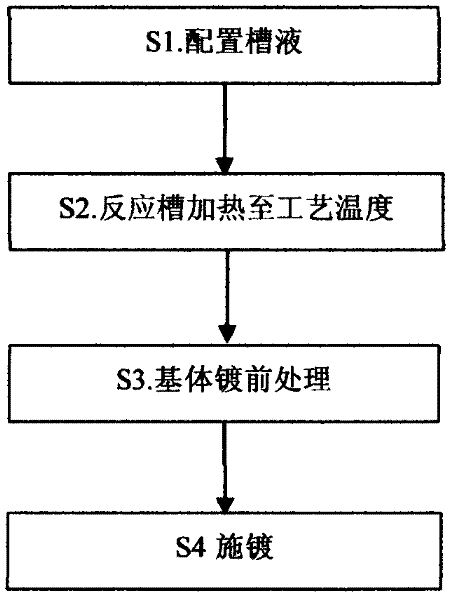

[0015] Figure 2 , the ion dialysis electroless nickel plating process on the substrate is:

[0016] S1, configure bath solution.

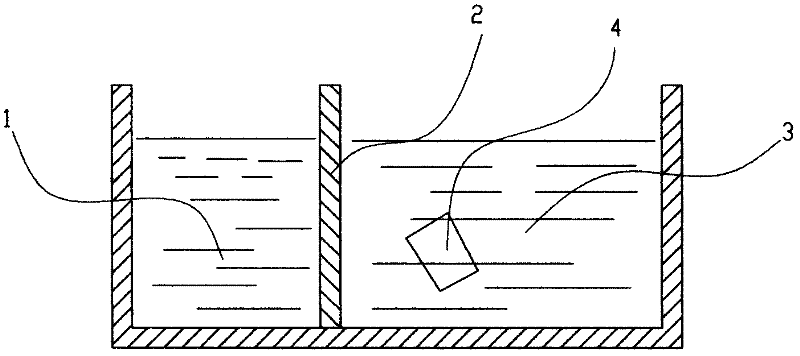

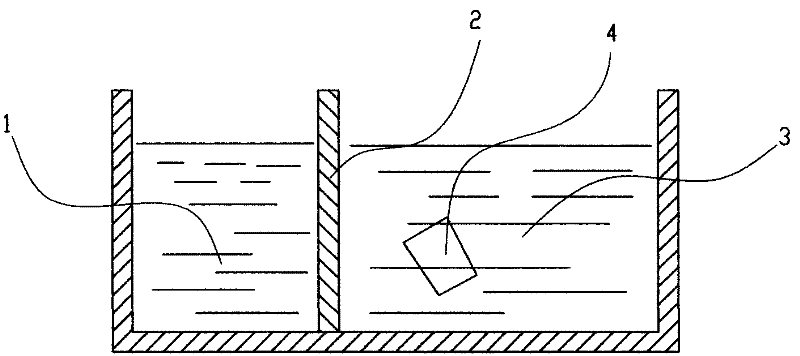

[0017] In the main salt tank 1, a main brine solution containing nickel ions of a certain concentration is prepared. Preferred nickel salts include nickel chloride, nickel sulfate, and the like. The preferred nickel salt concentration is 10 g / L to saturation in aqueous solution.

[0018] In the reaction tank 3, a tank solution including a reducing agent, a complexing agent, and a pH buffering agent is prepared. The preferred reducing agent includes sodium hypophosphite, and the preferred concentration of sodium hypophosphite is 10g / L-50g / L. Preferred complexing agents include citric acid, lactic acid, malic acid, etc., and the preferred complexing agent concentration is 5g / L-30g / L. The preferred pH buffering agent includes sodium acetate, etc., the preferred concentration of the...

Embodiment 2

[0025] Embodiment two ion dialysis electroless copper plating

[0026] Figure 2 , the ion dialysis electroless copper plating process on the substrate is:

[0027] S1, configure bath solution.

[0028] In the main salt tank 1, a main brine solution containing copper ions of a certain concentration is prepared. Preferred copper salts include copper chloride, copper sulfate, and the like. The preferred copper salt concentration is 10 g / L to saturation in aqueous solution.

[0029] In the reaction tank 3, a tank solution including a reducing agent, a complexing agent, and a pH buffering agent is prepared. The preferred reducing agent includes sodium hypophosphite, and the preferred concentration of sodium hypophosphite is 10g / L-50g / L. Preferred complexing agents include citric acid, lactic acid, malic acid, etc., and the preferred complexing agent concentration is 5g / L-30g / L. The preferred pH buffering agent includes sodium acetate, etc., the preferred pH buffering agent c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com