Single-chip magnetic sensor, and laser heating-assisted annealing apparatus thereof and laser heating-assisted annealing method thereof

A magnetic sensor and annealing device technology, which is applied in the manufacture/processing of electromagnetic devices, measuring devices, and resistors controlled by magnetic fields, can solve the problems that GMR and MTJ silicon wafers cannot be annealed, and achieve good magnetoresistance matching, Excellent performance and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Attached below Figure 1-13 The preferred embodiments of the present invention are described in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

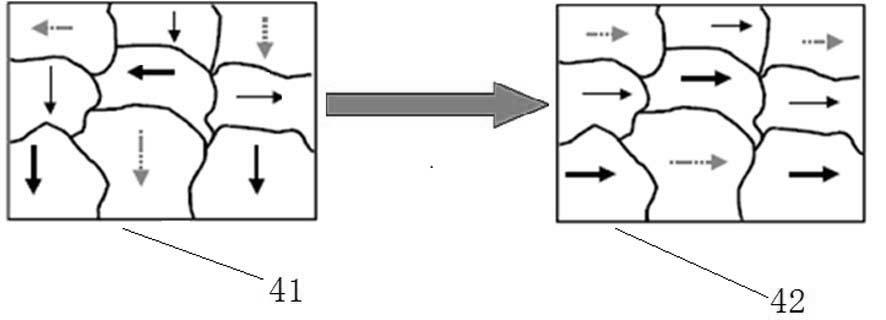

[0053] as attached image 3 Shown is a schematic diagram of the direction reversal of the magnetic moment in the magnetic domain under the external magnetic field. The direction 41 of the magnetic moments in the magnetic domains of the pinned layer in the normal state of the magnetic thin film is the orientation of the magnetic moments in the magnetic domains of the magnetic thin film without magnetic domain flipping. In the absence of an external field, the magnetic moments in the domains are randomly oriented. By applying an external magnetic field H, when the magnitude of the magnetic field H is large enough, the magnetic moment in the magnetic domain can be reversed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com