Method for growing zinc oxide material by modulating temperature periodically

A periodic modulation and zinc oxide technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of not using large-scale, industrial production, and limited practical value, and achieve low cost, low cost, The effect of high growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

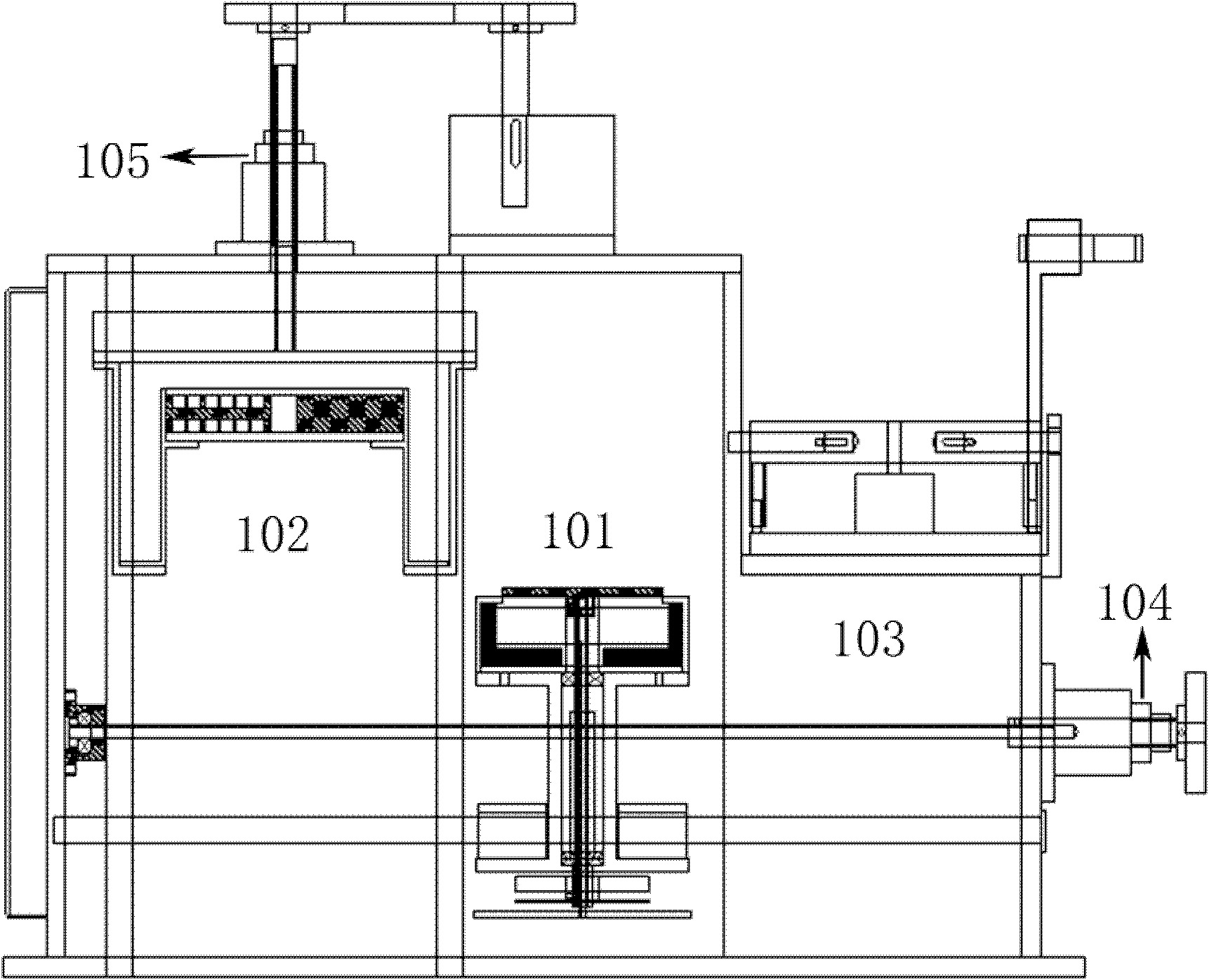

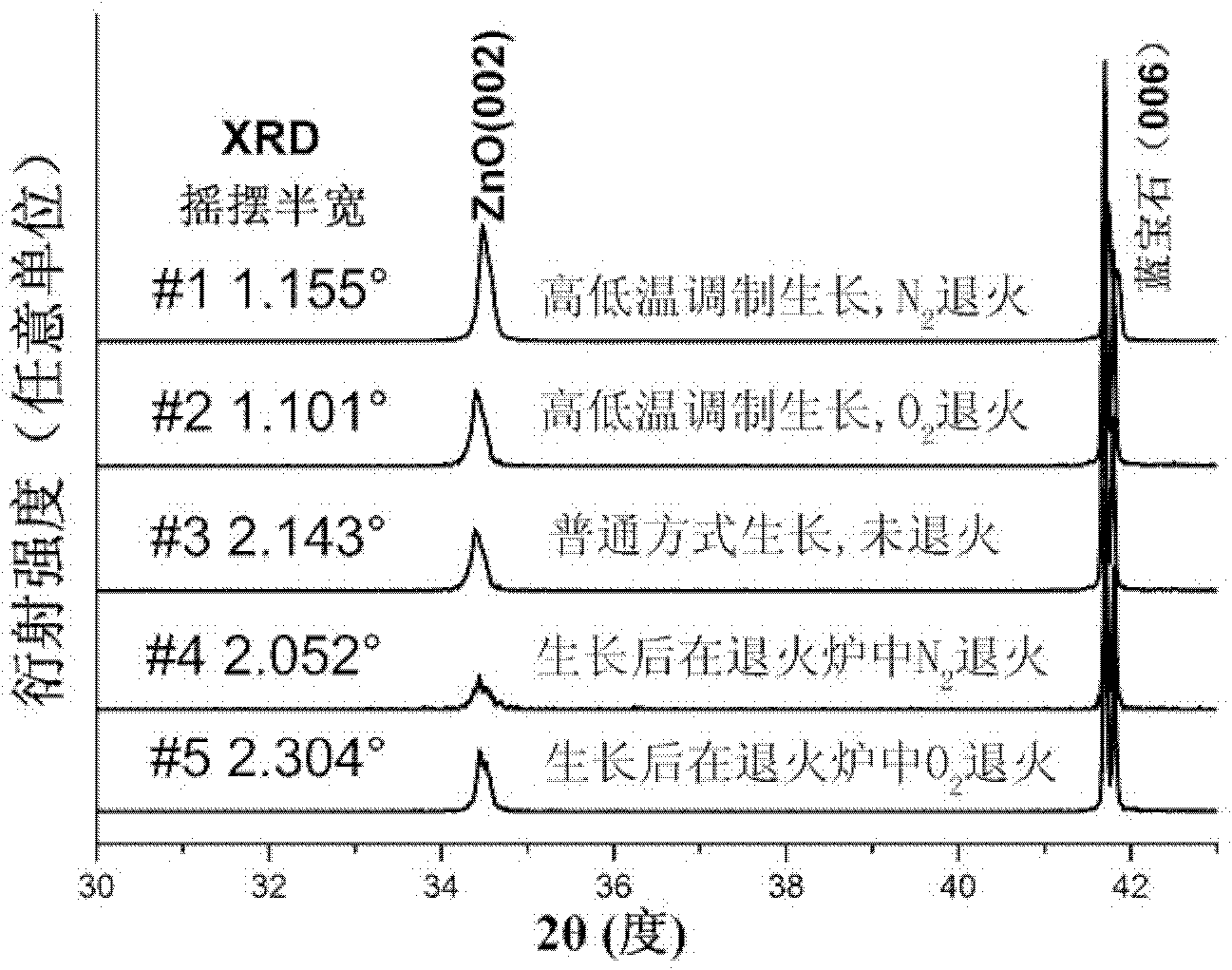

[0031] The key of the present invention is to use high and low temperature cycle modulation to grow zinc oxide material in MOCVD equipment. Since the existing MBE temperature modulation growth technology is limited by cost, growth speed and too small laser annealing area, we conduct temperature cycle modulation growth of ZnO material in self-made MOCVD equipment. Laughing gas can be used as the oxygen source and N doping source for the growth of ZnO materials at the same time, which reduces the complexity of the MOCVD gas path and operating system, and is conducive to the realization of industrial growth. At the same time, compared with traditional MOCVD equipment, the low-temperature growth and high-temperature annealing of ZnO in the present invention can be continuously and repeatedly carried out in the same MOCVD reaction chamber, which greatly improves the efficiency and reduces the pollution caused by taking out samples for annealing.

[0032] Please refer to the attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com