Low-roll-force gas-transmission pipeline steel and production method thereof

A technology of gas transmission pipeline and production method, which is applied in the field of metallurgical steel, can solve the problems of difficult steelmaking, excessively high and strict requirements, and high capacity requirements of rolling mills, and achieve the effect of simple process adjustment and improved operation status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

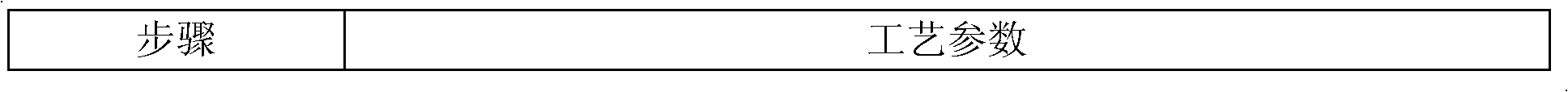

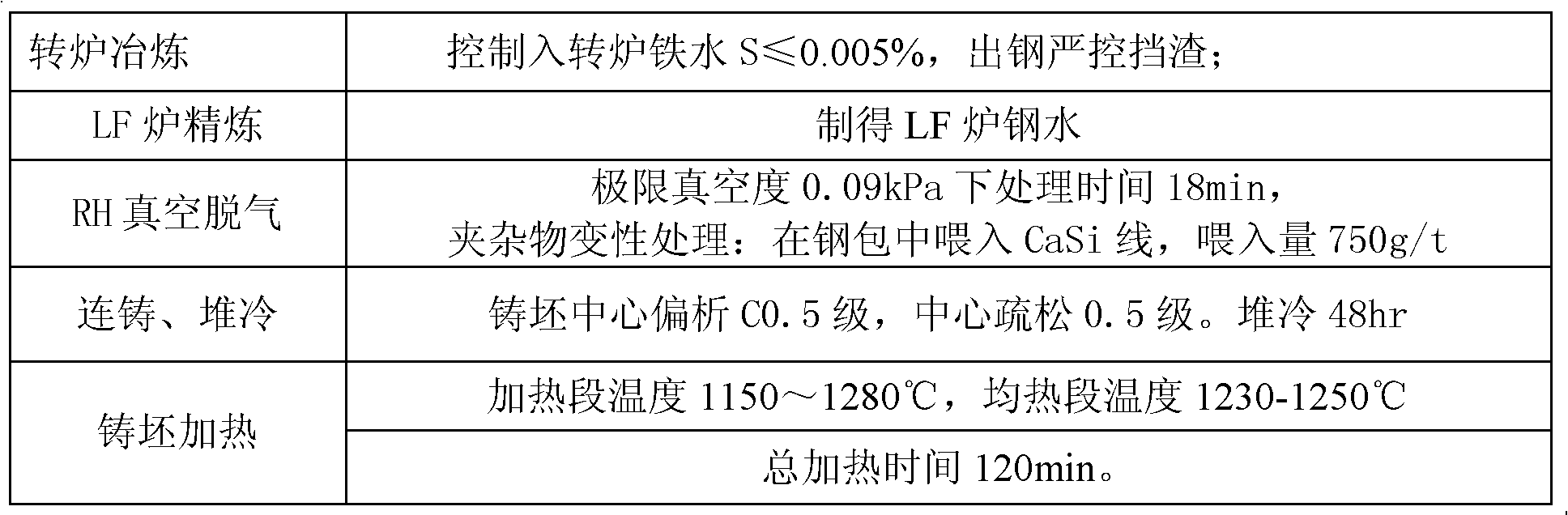

[0060] Within the scope of the chemical composition of the present invention, determine the chemical composition of Example 1 as shown in Table 1, wherein all control As≤0.03, Sn≤0.02, Sb≤0.02 (the following examples 2 and 3 are the same), smelting and casting steps and control The parameters are shown in Table 2, the controlled rolling and cooling steps and control parameters are shown in Table 3, the main control parameters of the X70 pipeline steel plate obtained are summarized in Table 4, and the mechanical properties of the finished steel are shown in Table 5. The typical metallographic structure obtained is acicular ferrite + granular bainite + a small amount of massive ferrite.

[0061] Chemical composition (wt%) of table 1X70 pipeline steel

[0062] C

mn

Si

P

S

Mo

Nb

Ti

0.06

1.5

0.20

0.010

0.002

0.143

0.04

0.012

Alt

Ca

N

0

Ti / N

Ca / Alt

Fe

other impurit...

Embodiment 2

[0071] Within the scope of the chemical composition of the present invention, the chemical composition of Example 2 is determined as shown in Table 5, the smelting and casting steps and control parameters are as shown in Table 6, the controlled rolling and cooling steps and control parameters are as shown in Table 7, and the obtained The main control parameters of X70 pipeline steel plate are summarized in Table 8.

[0072] Chemical composition (wt%) of table 5X80 pipeline steel

[0073] C

mn

Si

P

S

Mo

Cu

Ni

Nb

0.03

1.6

0.23

0.009

0.002

0.143

0.20

0.20

0.05

Ti

Alt

Ca

N

O

Ti / N

Ca / Alt

Fe

other impurities

0.006

0.028

0.0030

0.001

0.002

6

0.107

96.3

0.746

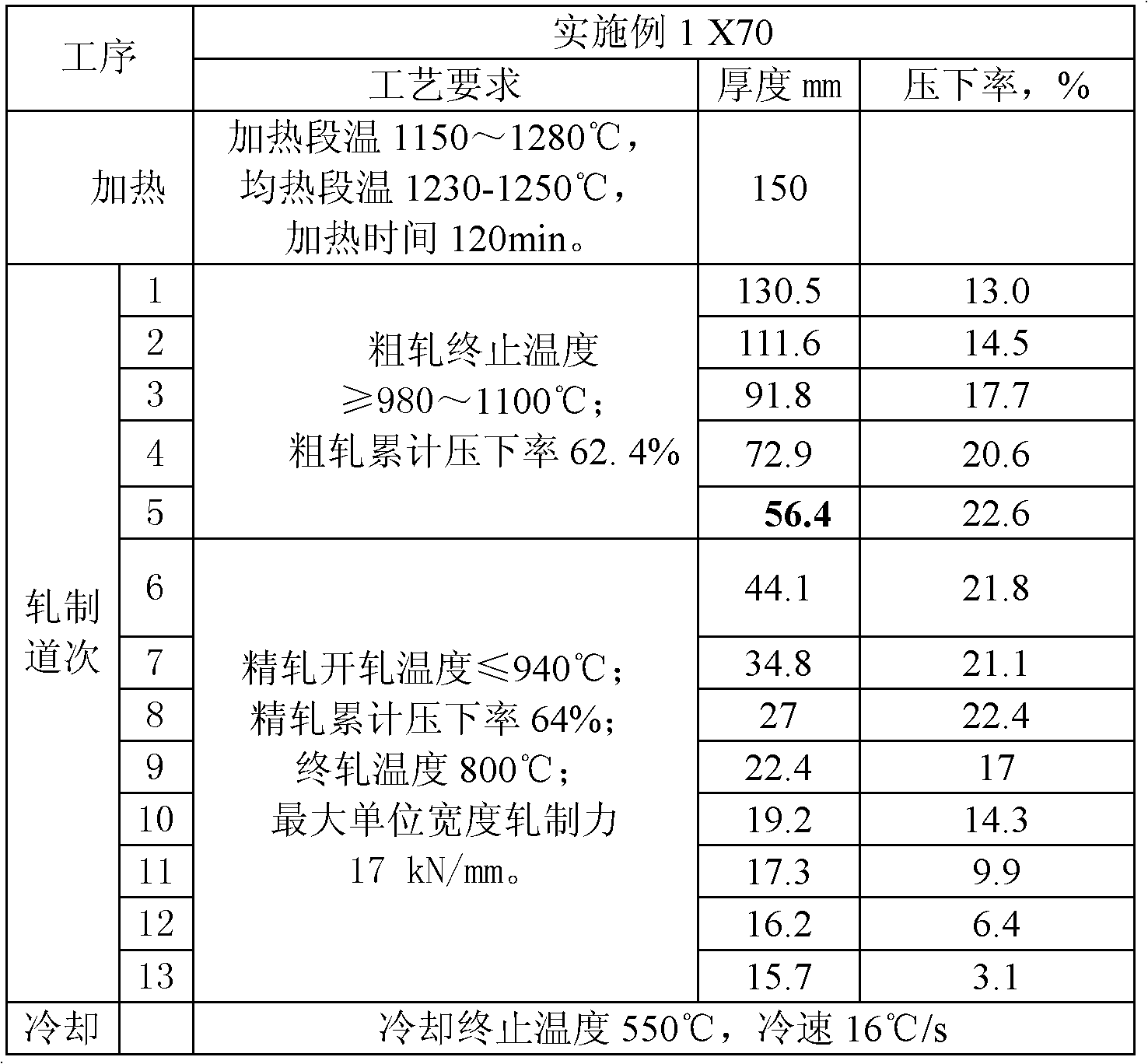

[0074] Table 6 X80 pipeline steel smelting and casting system

[0075]

[0076] Table 7 X80 pipeline steel controlled rolling and control...

Embodiment 3

[0082] Within the scope of the chemical composition of the present invention, the chemical composition of Example 3 is determined as shown in Table 9, the smelting and casting steps and control parameters are as shown in Table 10, the controlled rolling and cooling steps and control parameters are as shown in Table 11, and the obtained The main control parameters of X70 pipeline steel plate are summarized in Table 12.

[0083] Chemical composition (wt%) of table 9X60 pipeline steel

[0084]

[0085] Table 10X60 pipeline steel smelting and casting system

[0086]

[0087] Table 11 X60 pipeline steel controlled rolling and controlled cooling process system

[0088]

[0089] Table 12X60 pipeline steel characteristic parameters

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com