High-density polyethylene material and application thereof

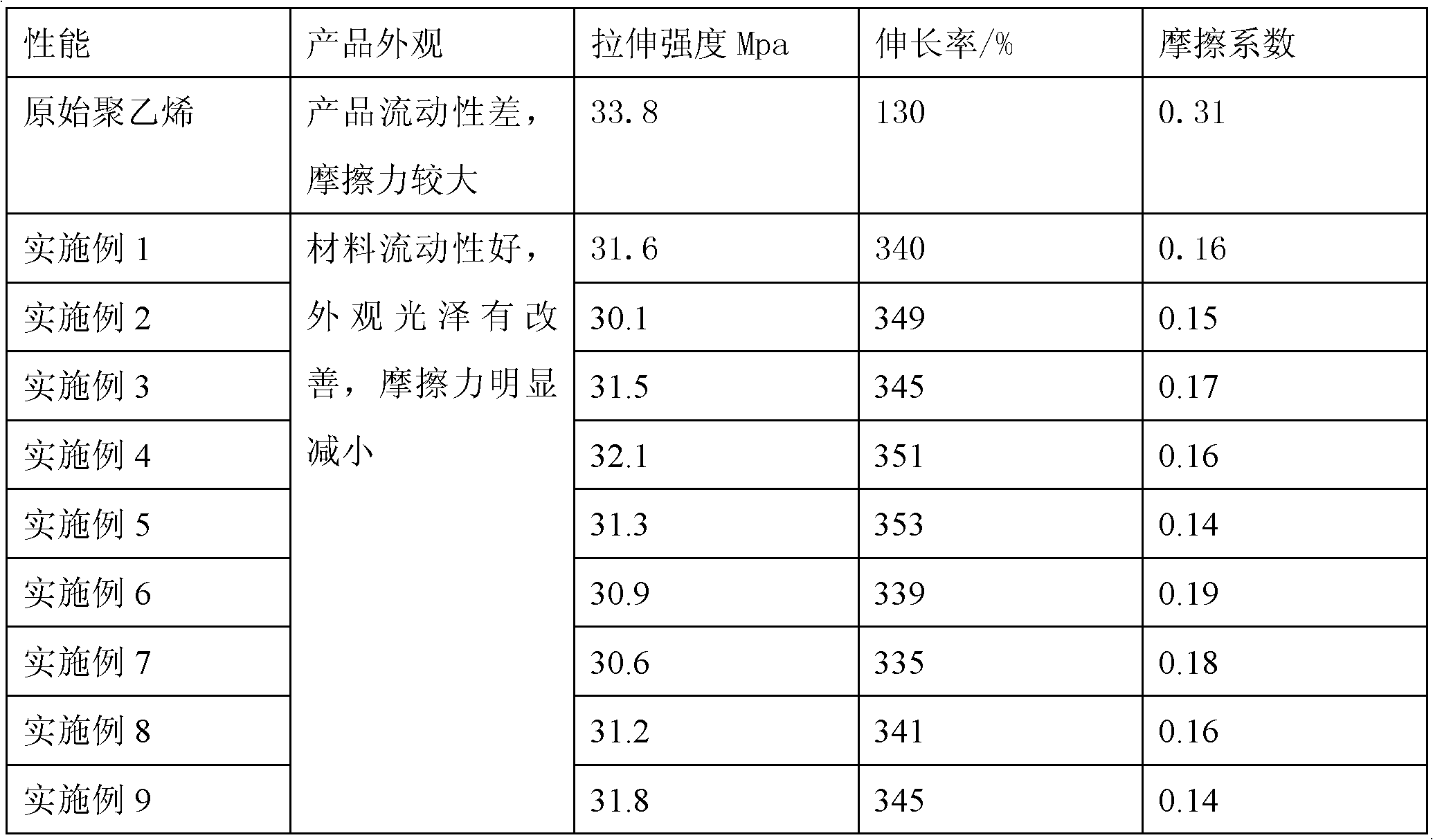

A technology of high-density polyethylene and terephthalic acid, applied in the direction of fiber mechanical structure, etc., can solve the problems of inconvenient construction of optical cable protection sleeve, poor product stability, high friction coefficient, etc., achieve good self-lubricating performance, reduce friction coefficient, good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: 100 parts by weight of high-density polyethylene, 80 parts of calcium terephthalate, 8 parts of active silicone oil, 5 parts of antioxidant 1010, mixed evenly by a vacuum kneader, and then using a twin-screw extruder at 170 ° C Extrude the mixed material into strips at high temperature and 1400 rpm, place it on the cross-section of the mold with a high-speed rotating cutter to cut it into pellets, and then cool it to get the finished product.

Embodiment 2

[0015] Embodiment 2: 100 parts by weight of high-density polyethylene, 70 parts of magnesium terephthalate, 8 parts of simethicone, 5 parts of antioxidant 168, after mixing uniformly by a vacuum kneader, use a twin-screw extruder to Extrude the mixed material into strips at a high temperature of 220°C and a speed of 1600 rpm, place it on the cross-section of the mold with a high-speed rotary cutter to cut it into pellets, and then cool it to obtain a finished product.

Embodiment 3

[0016] Embodiment 3: 100 parts by weight of high-density polyethylene, 5 parts of zinc terephthalate, 5 parts of 201 methyl silicone oil, 4 parts of antioxidant 264, after mixing uniformly by a vacuum kneader, use a twin-screw extruder to Extrude the mixed material into strips at a high temperature of 180°C and a speed of 1500 rpm, place it on the cross-section of the mold with a high-speed rotary cutter, cut it into pellets, and then cool it to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com