Method for separating and purifying two fragrance precursors from tobacco

A technology for separation and purification of tobacco, applied to β-4, separation and purification of α-4, can solve the problems of high preparation cost, limited development, complicated process operation, etc., and achieve high recovery rate, high degree of automation, and simple process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for separating and purifying α-4,8,13-cembretriene-1,3-diol and β-4,8,13-cembretriene-1,3-diol in tobacco, the process flow is as follows figure 1shown, including the following steps:

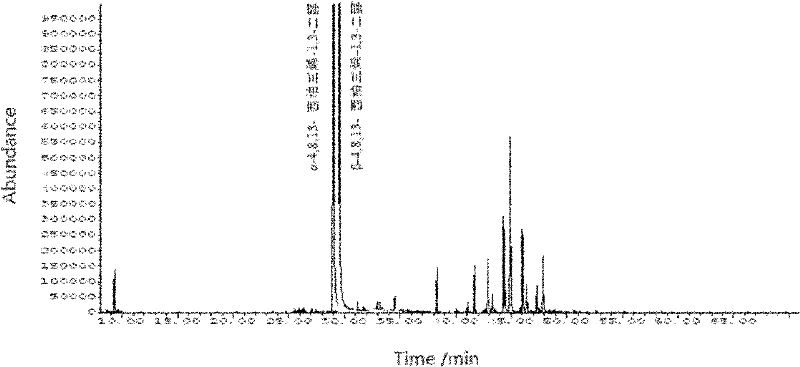

[0042] (1) Extraction: 1000 fresh tobacco leaves were collected from K326 flue-cured tobacco leaves in the tobacco leaf producing area of Yuxi City, Yunnan Province. The leaves were continuously dipped in 10 L of dichloromethane for 3 times, each time for 2 s. After dipping, the solution was filtered with filter paper filled with anhydrous sodium sulfate. The filtrate was concentrated to dryness under reduced pressure (10-13 kPa) at 40° C. to obtain about 80 g of dark brown extract. Detected by GC / MS, as follows figure 2 The chromatogram of the surface secretion extract of fresh tobacco leaves shown, it can be seen from the figure that the target α-4,8,13-cembretriene-1,3-diol and β-4,8,13-cembretriene The total content of -1,3-diol was 67.6%.

[0043] (2) Liquid-liquid e...

Embodiment 2

[0049] A method for separating and purifying α-4,8,13-cembretriene-1,3-diol and β-4,8,13-cembretriene-1,3-diol in tobacco, the process flow is as follows figure 1 shown, including the following steps:

[0050] (1) Extraction: 1000 fresh tobacco leaves were collected from K326 flue-cured tobacco leaves in the tobacco leaf producing area of Yuxi City, Yunnan Province. The leaves were continuously dipped in 10 L of chloroform for 3 times, each time for 2 s. After dipping, the solution was filtered with filter paper filled with anhydrous sodium sulfate. The filtrate was concentrated to dryness under reduced pressure (10-13 kPa) at 40° C. to obtain about 80 g of dark brown extract. By GC / MS detection, the total content of the target α-4,8,13-cembretriene-1,3-diol and β-4,8,13-cembretriene-1,3-diol was 67.6% .

[0051] (2) Liquid-liquid extraction: Weigh 20g of tobacco leaf surface secretion extract and place it in a 250ml conical flask, add 50ml of methanol-water (50:50) mixed...

Embodiment 3

[0056] Except in step (2), the volume ratio of n-hexane, methanol and water in the mixed extraction solvent is 100:90:10, the vacuum degree of the rotary evaporator in step (3) and step (4) is 300mbar and step (5) Except that the vacuum degree of the rotary evaporator is 60mbar, other steps are the same as in Example 1, and the obtained α-4,8,13-cembretriene-1,3-diol and β-4,8,13-cembretriene -1,3-Diol was 2.1g and 680mg, respectively, and the purity was more than 99%; The recoveries of 1,3-diol relative to tobacco leaf surface secretion extract were 10.5% and 3.4%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com