Method for casting super-large type semi-gear ring

A semi-ring gear, extra-large technology, which is applied in casting molding equipment, casting molds, cores, etc., can solve the problems of long contact time between molten steel and molding sand, large diameter of the half-ring gear, affecting product quality, etc., to reduce magnetic powder. The effect of flaw detection, dense tissue, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

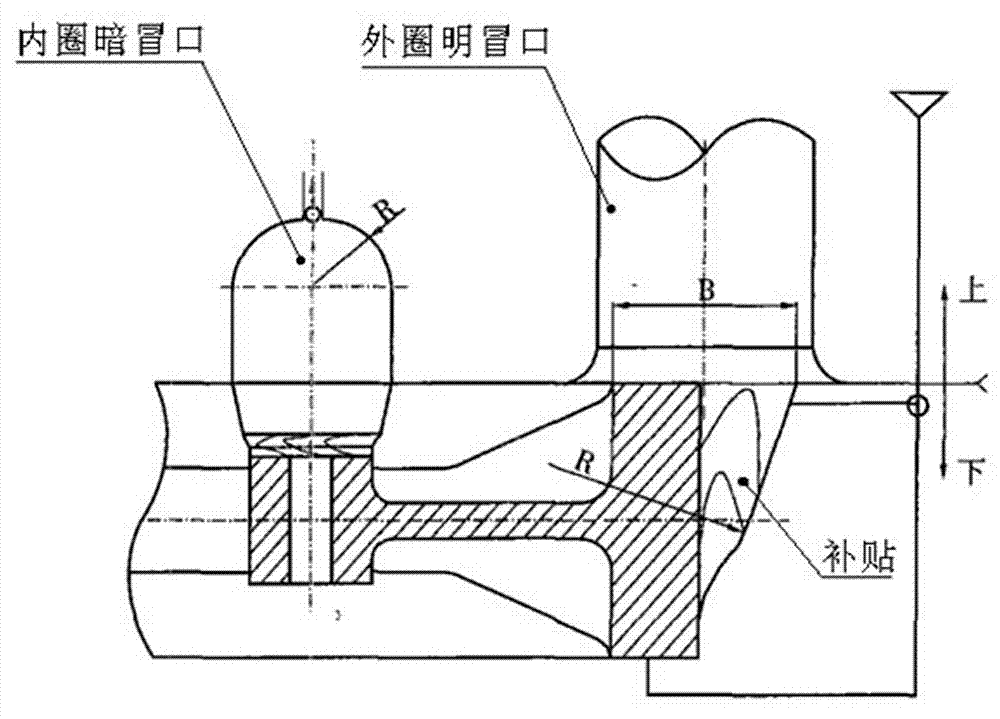

[0024] A casting method for a super-large semi-gear ring with a diameter of 9400mm, which adopts a full-circle open riser on the outer rim, plus an insulation riser cover, subsidizes the inner circle, and chills the outer circle with cold iron; the inner rim is scattered with circular insulation and hidden risers mouth, corresponding to the chilling of the bottom cold iron, to obtain the semi-gear blank, which specifically includes the following steps:

[0025] (1) Build the mold

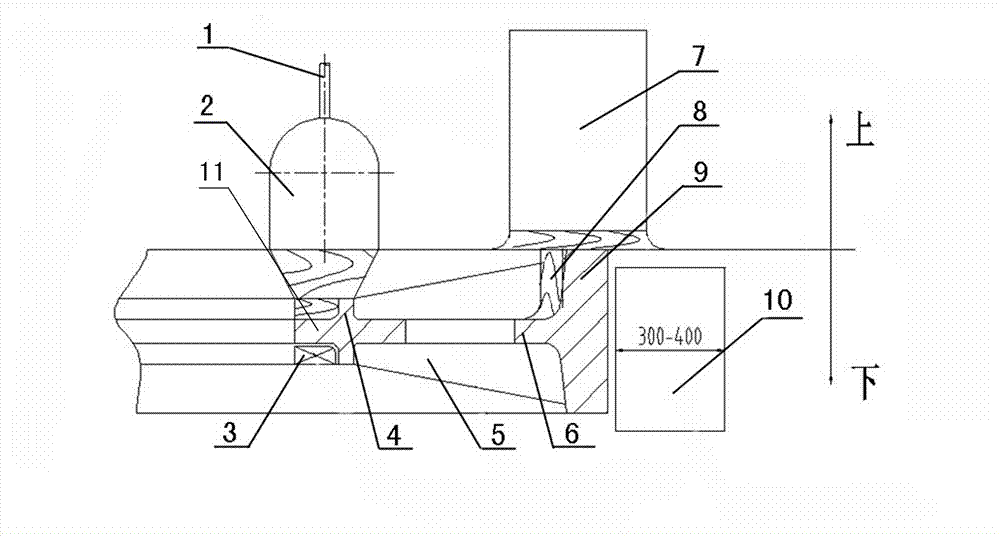

[0026] See the attached schematic diagram of the local structure of the casting mold process. figure 2 As shown, two half ring gears 11 are constructed with molding sand, and the distance between the centers of the two half ring gears 11 is 400mm. The plates are fixedly connected by bolts;

[0027] Along the upper part of the outer rim 9 of the two half-gears 11, a full-circle open riser 7 is arranged, and the open riser 7 is centrally arranged on the upper part of the outer rim 9. The width of t...

Embodiment 2

[0032] A casting method for a super-large semi-gear ring with a diameter of 10160mm, using a full-circle open riser on the outer rim, adding an insulation riser cover, subsidizing the inner circle, chilling the outer circle with cold iron; scattered circular insulation and hidden risers on the inner rim mouth, corresponding to the chilling of the bottom cold iron, to obtain the semi-gear blank, which specifically includes the following steps:

[0033] (1) Build the mold

[0034] See the attached schematic diagram of the local structure of the casting mold process. figure 2 As shown, two half-gears 11 are constructed with molding sand, and the distance between the centers of the two half-gears 11 is 450mm. The plates are fixedly connected by bolts;

[0035] Along the upper part of the outer rim 9 of the two half-gears 11, a full-circle open riser 7 is arranged, and the open riser 7 is centrally arranged on the upper part of the outer rim 9. The width of the open riser 7 alon...

Embodiment 3

[0040] A casting method for a super-large semi-gear ring with a diameter of 11630mm, which adopts a full-circle open riser on the outer rim, plus an insulation riser cover, subsidizes the inner circle, and chills the outer circle with cold iron; the inner rim is scattered with circular insulation and hidden risers mouth, corresponding to the chilling of the bottom cold iron, to obtain the semi-gear blank, which specifically includes the following steps:

[0041] (1) Build the mold

[0042] See the attached schematic diagram of the local structure of the casting mold process. figure 2 As shown, two half ring gears 11 are constructed with molding sand, and the distance between the centers of the two half ring gears 11 is 500mm. The plates are fixedly connected by bolts;

[0043] Along the upper part of the outer rim 9 of the two half-gears 11, a full-circle open riser 7 is arranged, and the open riser 7 is centrally arranged on the upper part of the outer rim 9. The width of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com