New efficient separation process of low-grade copper nickel sulfide ore

A sulfide ore, low-grade technology, which is applied in the field of new high-efficiency separation of low-grade copper-nickel sulfide ore, can solve the problem that the recovery rate of useful minerals is not ideal, and achieve a simplified flotation reagent system and nickel recovery rate. The effect of improving and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

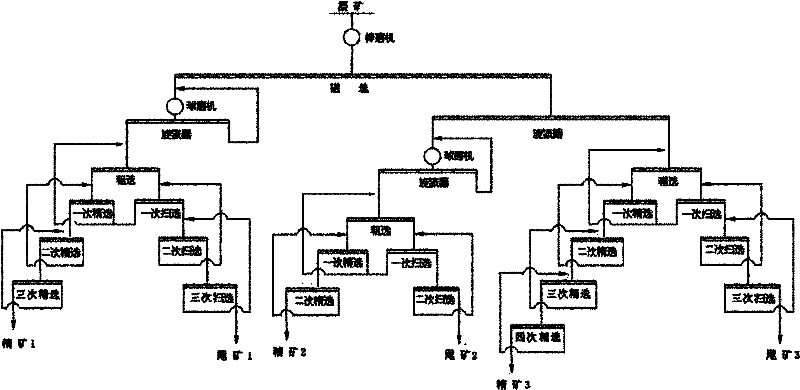

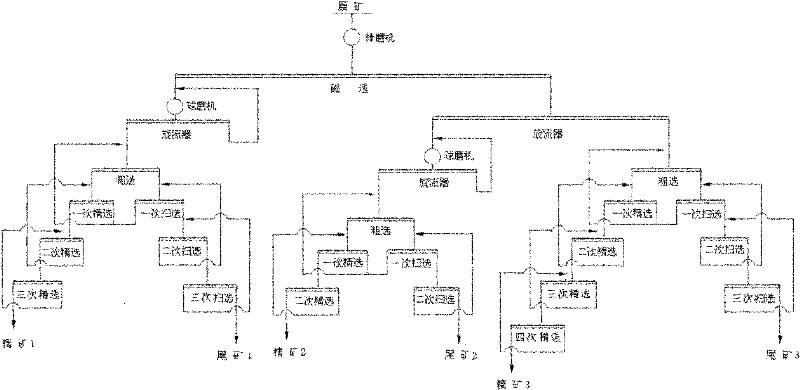

Image

Examples

Embodiment 1

[0021] The low-grade nickel sulfide ore used in this example is Jinchuan Low-grade nickel sulfide ore in the mining area. Through spectral and multi-element analysis, the ore has a nickel grade of 0.4%, a copper grade of 0.25%, an iron grade of 10%, a sulfur grade of 2%, and a magnesium oxide grade of 32%. It is a low-grade high-magnesium oxide copper-nickel sulfide ore. Through the analysis of optical microscope, scanning electron microscope and energy spectrometer, the copper-nickel minerals in the ore are mainly violazite, chalcopyrite, black copper ore, a small amount of nickel-copper microcrystalline aggregates, etc. At the same time, it contains about 9% iron oxides such as magnetite, and the gangue minerals are silicate minerals such as serpentine, dolomite and chlorite.

[0022] Jinchuan The low-grade copper-nickel sulfide ore in the mining area is subjected to a first-stage rod grinding, and the grinding fineness is -0.074mm, accounting for 10%. The magnetic separ...

Embodiment 2

[0026] The low-grade nickel sulfide ore used in this implementation example is Jinchuan Low-grade nickel sulfide ore in the mining area. Through spectrum and multi-element analysis, the ore has a nickel grade of 0.5%, a copper grade of 0.30%, an iron grade of 10%, a sulfur grade of 2.3%, and a magnesium oxide grade of 30%. It is a low-grade high-magnesium oxide copper-nickel sulfide ore. Through the analysis of optical microscope, scanning electron microscope and energy spectrometer, the copper-nickel minerals in the ore are mainly purple sulfur nickelite (pentlandite), chalcopyrite, black copper ore, a small amount of nickel-copper microcrystalline aggregates, etc. At the same time, it contains about 10% iron oxides such as magnetite, and the gangue minerals are silicate minerals such as serpentine, dolomite and chlorite.

[0027] Jinchuan The low-grade copper-nickel sulfide ore in the mining area is subjected to a first-stage rod grinding, and the grinding fineness is -0...

Embodiment 3

[0031] The low-grade nickel sulfide ore used in this implementation example is Jinchuan Low-grade nickel sulfide ore in the mining area. Through spectrum and multi-element analysis, the ore has a nickel grade of 0.61%, a copper grade of 0.38%, an iron grade of 10%, a sulfur grade of 2.4%, and a magnesium oxide grade of 29%. It is a low-grade high-magnesium oxide copper-nickel sulfide ore. Through the analysis of optical microscope, scanning electron microscope and energy spectrometer, the copper-nickel minerals in the ore are mainly purple sulfur nickelite (pentlandite), chalcopyrite, black copper ore, a small amount of nickel-copper microcrystalline aggregates, etc. At the same time, it contains about 10% iron oxides such as magnetite, and the gangue minerals are silicate minerals such as serpentine, dolomite and chlorite.

[0032] Jinchuan The low-grade copper-nickel sulfide ore in the mining area is subjected to a first-stage rod grinding, and the grinding fineness is -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com