Contact pad for sensing the voltage of a cell module assembly, and cell module assembly

A unit module, voltage sensing technology, applied in the direction of electrical components, battery pack components, circuits, etc., can solve the problems of increasing the incidence of poor electrical contact, reducing productivity and operating efficiency, and low electrical contact reliability. Improved electrical contact reliability, reduced power loss, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

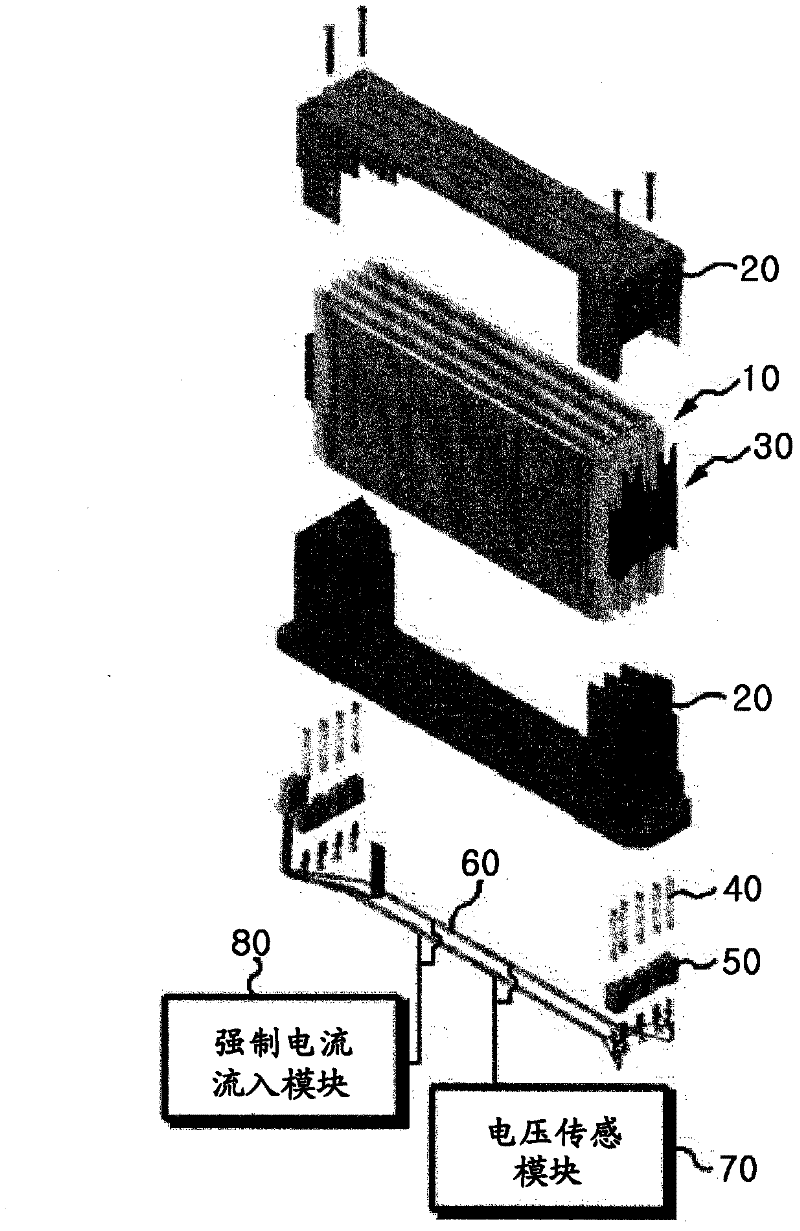

[0030] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the attached drawings. Previously, it is stated that the terms and vocabulary used in this specification and claims are not limited to the usual meaning or the meaning in the dictionary, and are based on the principle that the inventor can accurately define the concept of the term in order to describe the invention in the best way, It should be understood as the meaning and concept in line with the technical idea of the present invention.

[0031] The embodiments described in this specification and the structures shown in the drawings are only the best embodiments of the present invention, and cannot represent all the technical ideas of the present invention. Therefore, it should be understood that it can replace Various equivalents and modifications of these.

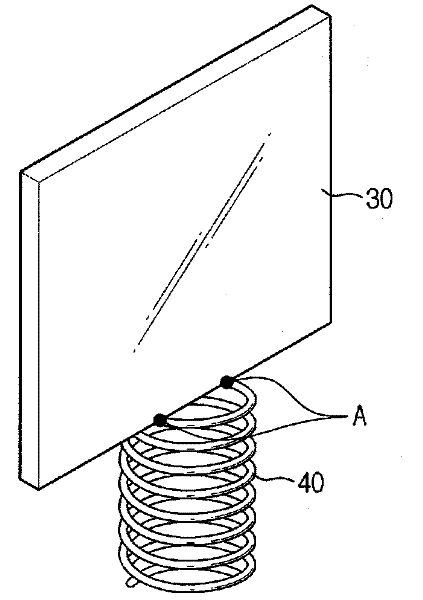

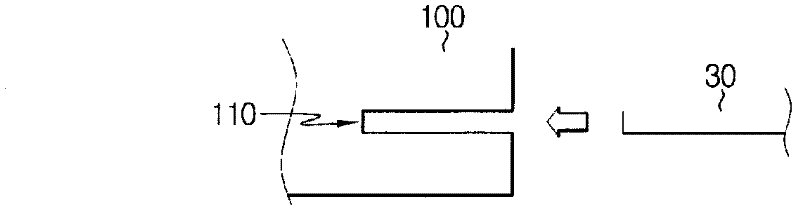

[0032] image 3 A cross-sectional view illustrating a contact pad of a preferred embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com