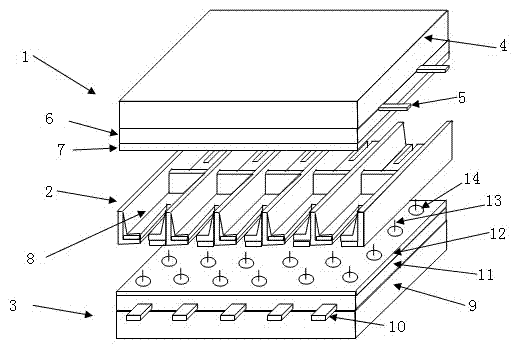

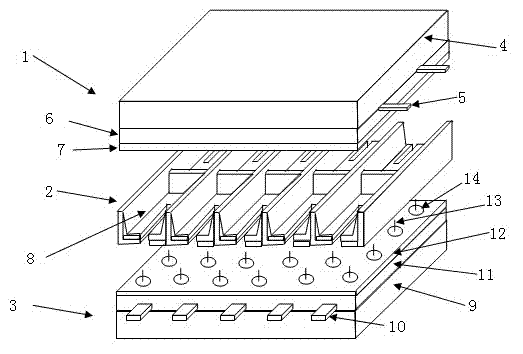

Shadow mask type plasma display panel

A plasma and display panel technology, applied in the direction of solid cathode parts, cold cathode tubes, etc., can solve the problems of loss of phosphor powder area, decrease of display panel brightness, etc., to achieve the effect of improving brightness, improving utilization efficiency, and avoiding mutual pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Example 1: According to the above embodiment, the thickness of the porous alumina layer should be controlled between 0.5 and 1.5 microns, and CNTs with a length of 1 to 2 microns are used to ensure that the CNTs can form vertical orientation in the alumina pores, which is A first set of embodiments of the invention.

example 2

[0026] Example 2: According to the above embodiment, the diameter of the alumina pores should be controlled within 30-50 microns so that CNTs can smoothly enter the alumina pores. This is the second group of embodiments of the present invention.

example 3

[0027] Example 3: According to the above embodiment, CNTs can choose a single-wall structure or a multi-wall structure. This is the third group of embodiments of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com