Composite foam black ceramic solar heat accumulating plate and producing method as well as production applications thereof

A solar collector plate and composite foam technology, which is applied in the field of ceramic manufacturing and ceramic product application, can solve the problems of high manufacturing cost, complex production process, and small thermal conductivity, and achieve firm internal structure, stable chemical properties, and small thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] 1. Composite foam black porcelain solar collector plate

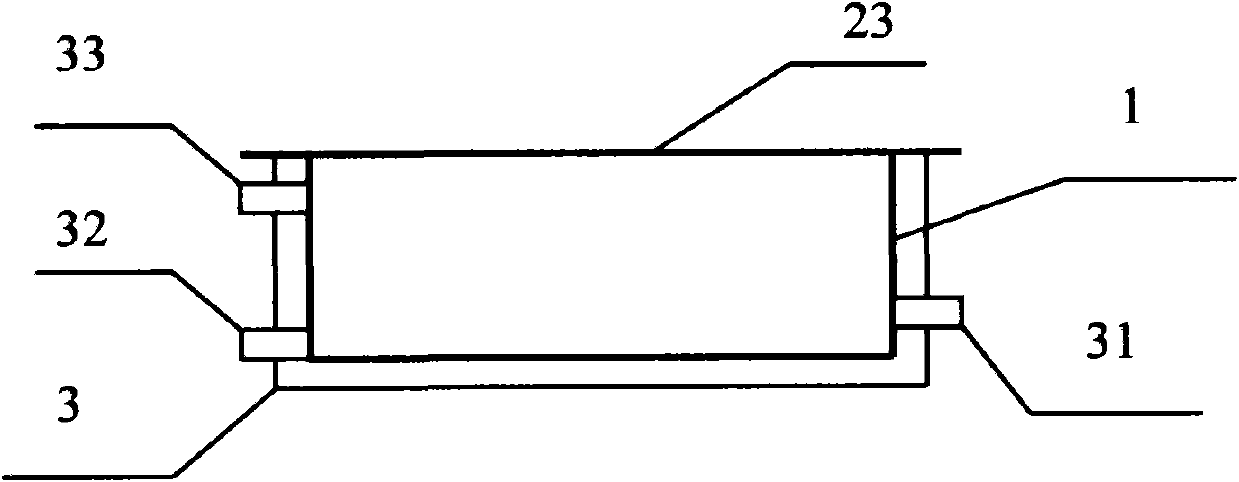

[0062] See attached figure 1 . A kind of composite foam black porcelain solar thermal collector plate 1, is made up of common ceramic layer 11, black porcelain layer 13, is characterized in that: also comprises foam ceramic layer 12, and foam ceramic layer 12 is positioned at middle layer, and common ceramic layer 11 is positioned at base layer, The black porcelain layer 13 is located on the surface layer, and the common ceramic layer 11 of the base layer, the foam ceramic layer 12 of the middle layer, and the black porcelain layer 13 of the surface layer are fired into one body. Among them, the thickness of the ordinary ceramic layer of the base layer is 3-8mm, the thickness of the foam ceramic layer of the middle layer is 10-20mm, and the thickness of the black porcelain layer of the surface layer is 1-2mm.

[0063] The production process of the present embodiment is as follows:

[0064] (1) Preparation of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com