Multi-laser high-precision 3D printer and printing method thereof

A 3D printer, 3D printing technology, applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., can solve the problems of low geometric accuracy of molded parts, affect the quality of molded products, restrict 3D printers, etc., and reduce residual stress , Stable internal structure, high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

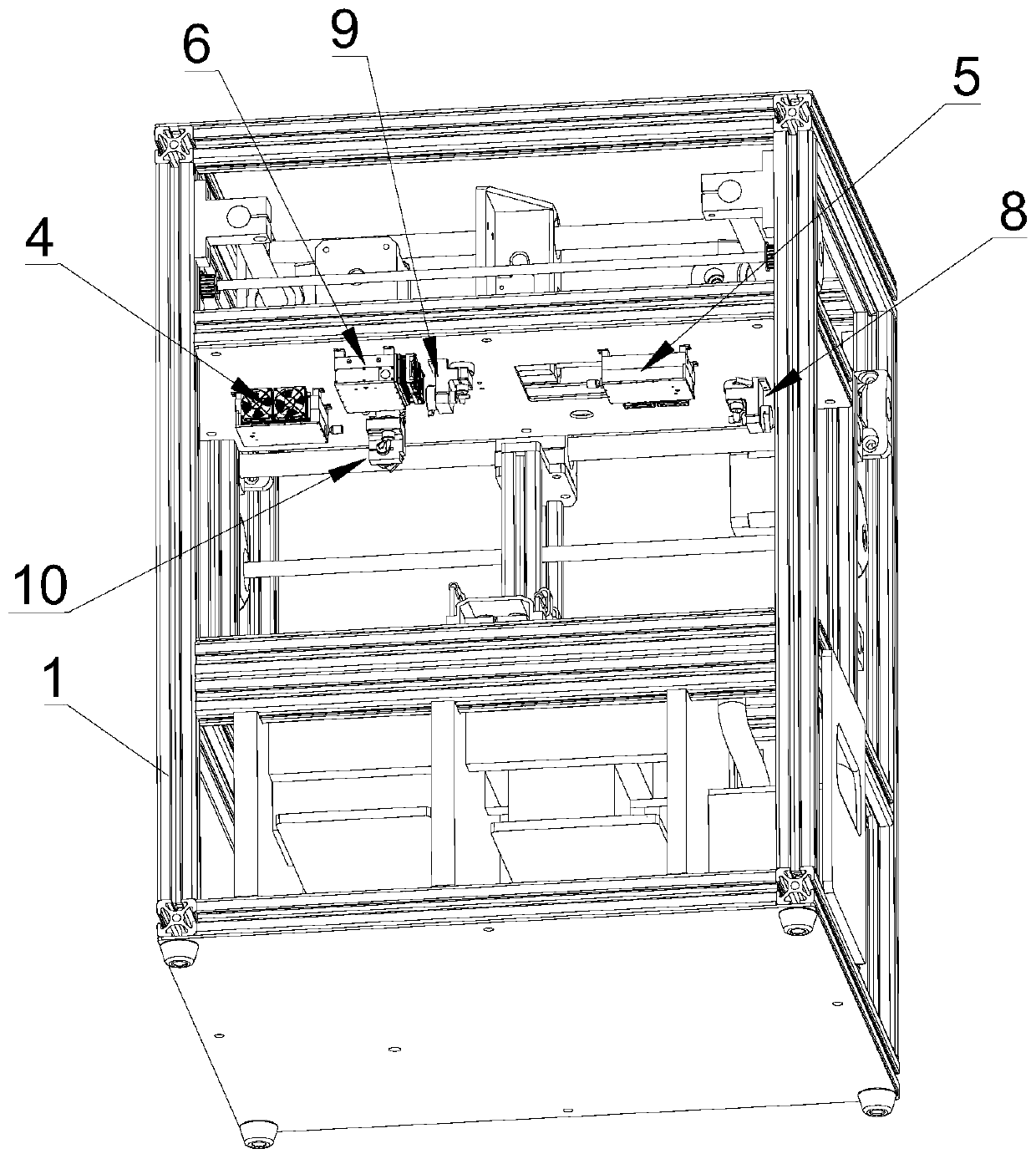

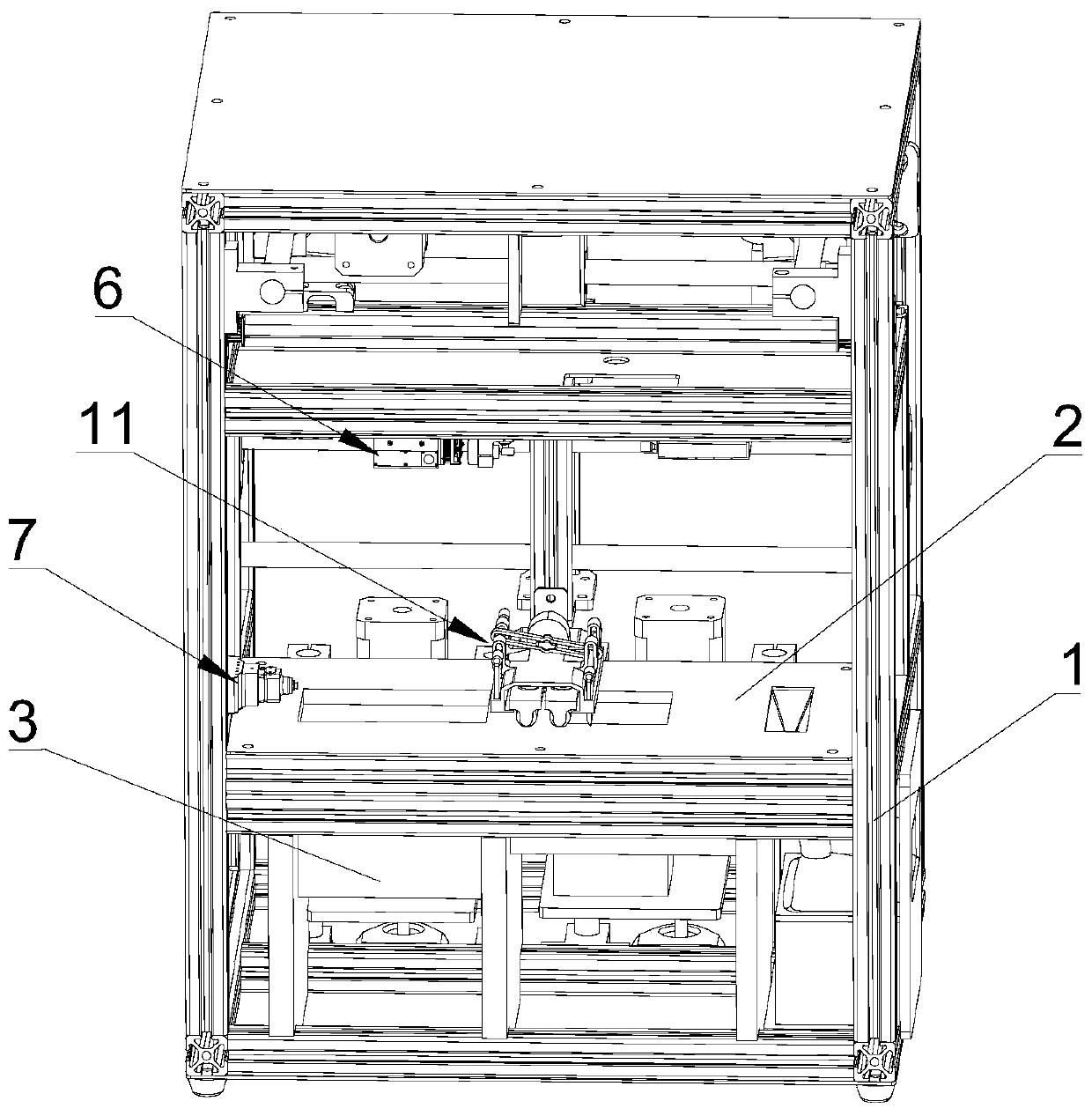

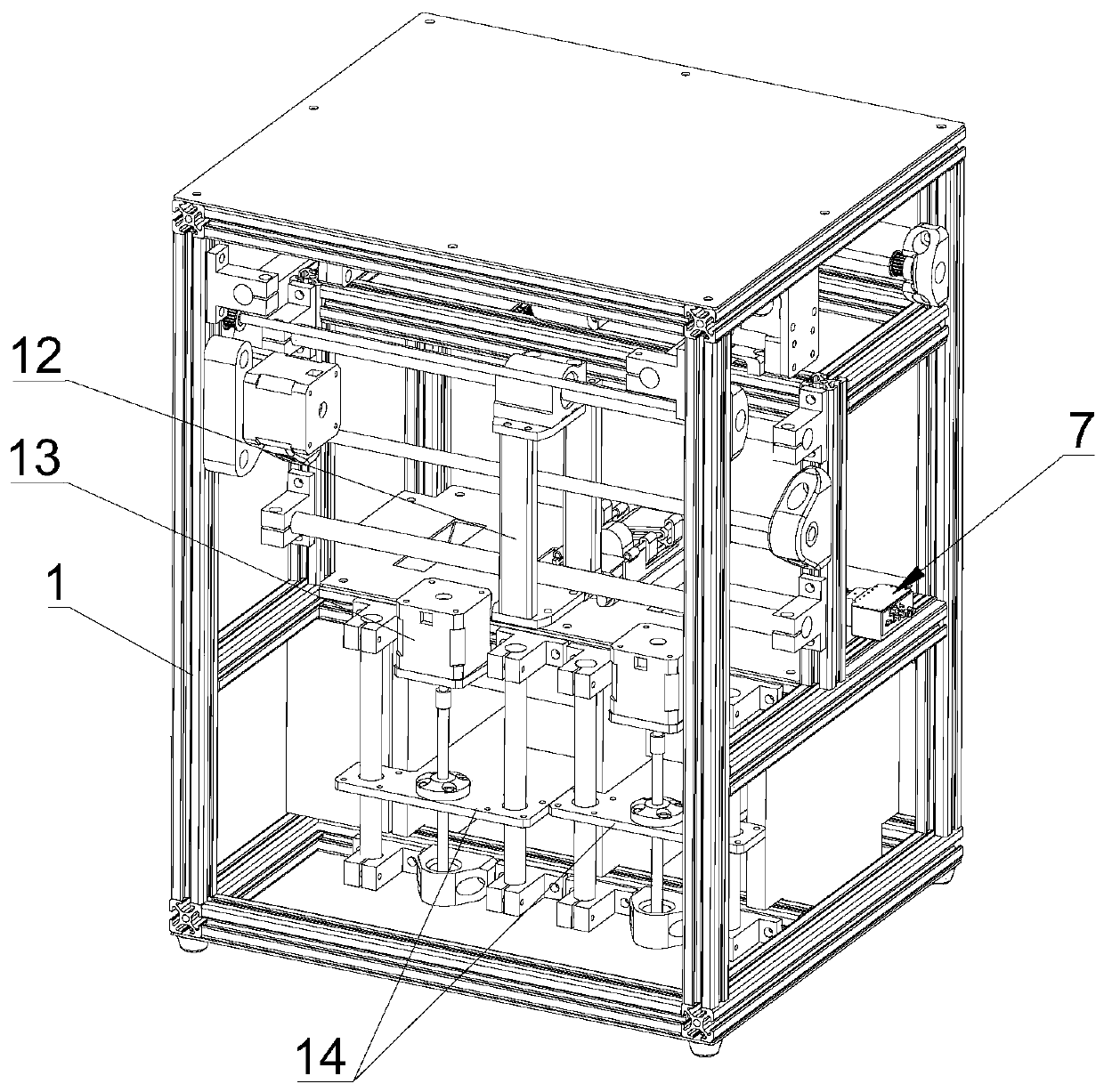

[0054] see Figure 1-3 , the multi-laser high-precision 3D printer in this embodiment includes a frame 1 and a powder storage module, a powder distribution module, a molding device, a laser sintering module, and a powder recovery module arranged on the frame 1. The molding device It includes a sintering platform 2, a base plate 3 and a lifting and forming mechanism. The sintering platform 2 is provided with a forming hole. In the forming hole, the space between the upper surface of the base plate 3 and the upper surface of the sintering platform 2 forms a forming cavity. The powder distributing module transports and places the powder stored in the powder storage module on the substrate 3 so that the laser sintering module can perform laser scanning.

[0055] see Figure 1-3 , the laser sintering module includes a preheating scanning module, a sintering scanning module and a trimming scanning module; wherein the preheating scanning module includes a preheating laser 4 for emitti...

Embodiment 2

[0085] see Image 6 , and the difference from Example 1 is that the sintering spot in this embodiment is located at the periphery of the preheating spot, and the diameter ratio of the preheating spot to the sintering spot is 5:2). When the preheating spot stops moving, the sintering spot first turns around Move around the center of the preheating spot, and then approach the center of the preheating spot. At this time, the sintering spot has covered the center of the preheating spot, and then the sintering spot moves around the center of the preheating spot to complete the preheating spot. The sintering work of all powder materials within the coverage range, and finally the sintering spot resets back to the periphery of the preheating spot to complete a gap cycle work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com