Method for preparing modified urea resin for coating abrasive tools

A technology of urea-formaldehyde resin and coated abrasives, which is applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., which can solve the problems of unsatisfactory bonding strength and poor heat resistance, and achieve heat resistance Improvement of sex and bonding strength, reduction of environmental pollution, and reduction of free formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

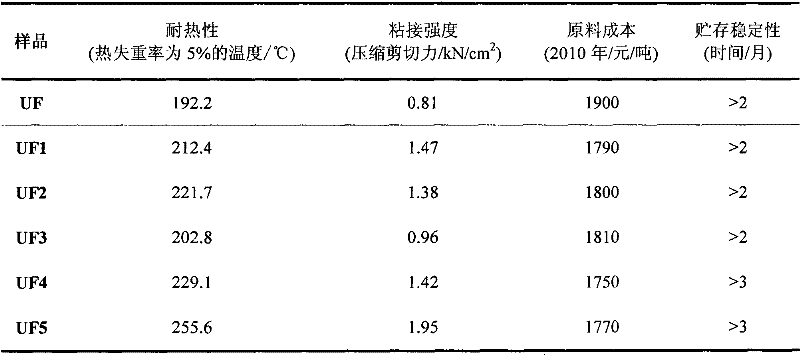

Examples

example 1

[0018] Under full stirring, weigh 40g of 37% formaldehyde aqueous solution and 0.015g of catalyst sodium hydroxide, add them into a four-neck flask with reflux condensation, add 8g of urea after the sodium hydroxide is completely dissolved, raise the temperature to 60°C and control the reaction The time is 30min, add 5g of urea, adjust the temperature to 85°C and maintain the reaction time for 90min, add 1.4g of glycerin, and then add 0.02g of acidic pH regulator ammonium chloride, control the reaction temperature to 95°C, and the reaction time to 20min, adjust The reaction temperature is 70°C, add 0.02g of sodium hydroxide, 7g of urea and 3.5g of soluble starch, add 1.7g of modified hydroxy silicone oil and 0.016g of sulfuric acid as a pH regulator after 15 minutes, and react at 70°C for 60 minutes, and the reaction is completed to obtain Modified urea-formaldehyde resin product UF1 with a solid content of 48.8%.

example 2

[0020] Under full stirring, weigh 40g of 37% formaldehyde solution, put it into a four-neck flask with reflux condensation, add 0.1g of catalyst ammonia water and 8g of urea, raise the temperature to 55°C and control the reaction time to 30min, add 5g of urea, adjust Temperature to 85°C and maintain the reaction time for 90min, add 1.4g of glycerin, then add 0.02g of acidic pH regulator ammonium chloride, control the reaction temperature to 95°C, the reaction time is 20min, adjust the reaction temperature to 70°C, add hydroxide Sodium 0.02g, urea 7g and soluble starch 2.6g, after 15min, add modified hydroxy silicone oil 1.7g and pH adjuster hydrochloric acid 0.033g, react at 70°C for 60min, the reaction is over, and the modified urea-formaldehyde with a solid content of 45.8% is obtained Resin product UF2.

example 3

[0022] Under full stirring, weigh 90g of 37% formaldehyde aqueous solution and 0.035g of catalyst sodium hydroxide, add them into a four-neck flask with reflux condensation, add 19.5g of urea after the sodium hydroxide is completely dissolved, raise the temperature to 60°C and control The reaction time is 30min, add 12g of urea, adjust the temperature to 85°C and maintain the reaction time for 90min, add 2.52g of glycerin, and then add 0.045g of catalyst ammonium chloride, control the reaction temperature to about 90°C, and the reaction time to 30min, adjust the reaction The temperature is 75°C, add 0.045g of sodium hydroxide, 16.5g of urea and 6.3g of soluble starch, add 4.2g of modified hydroxy silicone oil and 0.16g of pH regulator sulfuric acid after 15 minutes, and react at 75°C for 30 minutes, and the reaction is completed to obtain The modified urea-formaldehyde resin product UF3 with a solid content of 47.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com