Modified urea-formaldehyde resin, and preparation method and applications thereof

A urea-formaldehyde resin modification technology, applied in the preparation of fiberboard, in the field of modified urea-formaldehyde resin, can solve the problems of melamine secondary pollution and low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

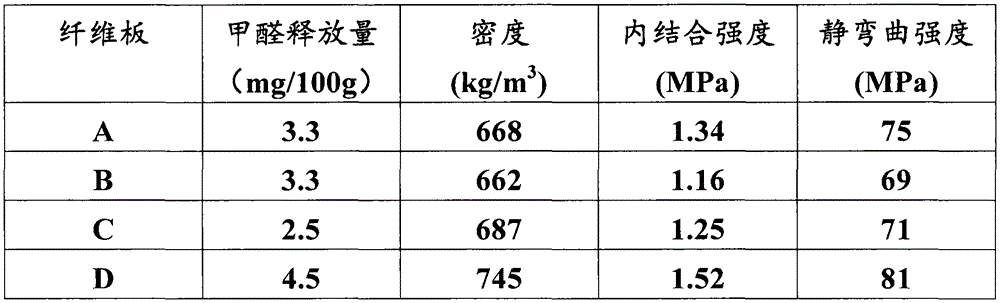

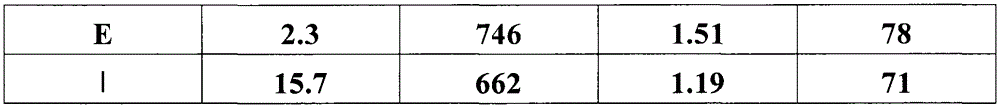

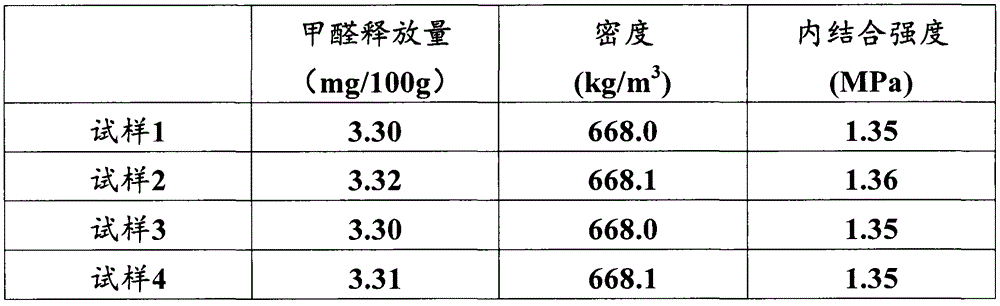

Examples

Embodiment 1

[0053] Add 10 parts by weight of urea-formaldehyde resin and 6.5 parts by weight of propyl p-hydroxybenzoate into a stirring tank, and mix at 50-70° C. to obtain modified urea-formaldehyde resin A.

[0054] Add the above-mentioned modified urea-formaldehyde resin A to 125 parts by weight of the fiber slurry and mix evenly, and dry the mixture at 50-70°C until the water content is 15wt%, to obtain a mixture. The mixture was pre-pressed at 4-5MPa for 30s to form a blank, and the blank was isostatically pressed at 8MPa and 70°C for 1min to form a slab. Hot press the slab, the hot pressing conditions are: temperature 110-120°C; rise to 13.5-19MPa within 20-30s, hold pressure for 60-120s; decompress to 3.5-5.5MPa within 10-15s, hold Press for 65-135s; then rise to 6-8.5MPa within 10-15s, hold the pressure for 50-75s; finally depressurize uniformly to 0MPa within 30-45s. The hot-pressed sheet was cooled to room temperature, tempered and sanded to obtain a fiberboard A with a thickn...

Embodiment 2

[0056] Add 20 parts by weight of urea-formaldehyde resin and 11 parts by weight of propyl p-hydroxybenzoate into a stirring tank, and mix at 50-70° C. to obtain modified urea-formaldehyde resin B.

[0057] The modified urea-formaldehyde resin B was added to 167 parts by weight of the fiber slurry for mixing, and the mixture was dried at 60-70° C. until the water content was 10 wt % to obtain a mixture. The mixture was pre-pressed at 4-5MPa for 40s to form a blank, and the blank was isostatically pressed at 7MPa and 70°C for 50s to form a slab. Hot press the slab, the hot pressing conditions are: temperature 110-120°C; rise to 13.5-19MPa within 20-30s, hold pressure for 60-120s; decompress to 3.5-5.5MPa within 10-15s, hold Press for 65-135s; then rise to 6-8.5MPa within 10-15s, hold the pressure for 50-75s; finally depressurize uniformly to 0MPa within 30-45s. The hot-pressed sheet was cooled to room temperature, tempered and sanded to obtain a fiberboard B with a thickness of...

Embodiment 3

[0059] Heat 100 parts by weight of formaldehyde to 35-40°C, adjust the pH value to 7.0-8.0 with 20-25 wt% sodium hydroxide solution, add 33-35 parts by weight of urea and 0.02-0.03 parts by weight of diatomaceous earth, and raise the temperature to 88 React at -90°C for 30-40min; use 20-25wt% sodium hydroxide solution to adjust the pH value of the above product to 6.5-7.5, add 17-19 parts by weight of urea and 0.01-0.02 parts by weight of diatomaceous earth, at 88-92°C The reaction is terminated when the mixture is dropped into 70-75°C water and becomes white mist; adjust the pH value of the above product to 7.5-7.8 with 25-30wt% sodium hydroxide solution, and when the temperature drops to 75-80°C, add 15- 17 parts by weight of urea and 0.02-0.03 parts by weight of diatomaceous earth were reacted for 20 minutes, and the filtrate was filtered; then 8-10 parts by weight of urea and 0.03-0.04 parts by weight of diatomaceous earth were added to the obtained filtrate, and the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com