Porous heterogeneous mesoporous material and preparation method thereof

A mesoporous material and heterogeneous technology, applied in the field of mesoporous materials, can solve the problems of poor stability, limited application, unable to adapt to the reaction conditions of heavy oil processing, etc., and achieve the effects of good thermal stability, uniform pore size distribution, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

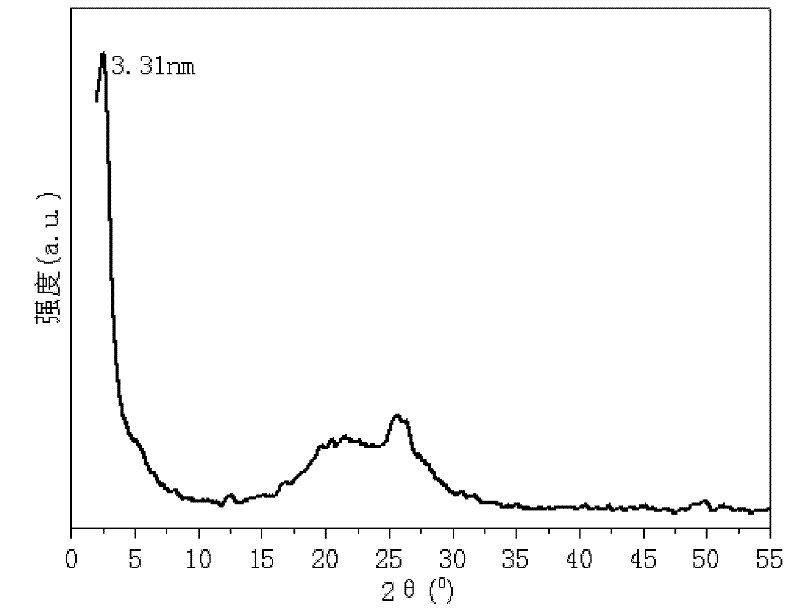

[0055] Raw materials: the magadiite sample prepared in Comparative Example 1, cetyltrimethylammonium bromide, ethyl orthosilicate (Beijing Chemical Plant), n-decylamine (product of Beijing Bailingwei Technology Co., Ltd.), deionized water.

[0056] Weigh 1 g of the magadiite sample prepared in Comparative Example 1, mix evenly with cetyltrimethylammonium bromide and deionized water at a molar ratio of 1:9.3:1773, stir at 60°C for 24 hours, wash with water, and centrifuge Afterwards, the sample was obtained by drying in a drying oven at 60° C. for 24 hours. Weigh again 2 g of the sample obtained after drying, mix it with n-decylamine and tetraethyl orthosilicate in a molar ratio of 1:20.5:144, stir for 6 hours, then centrifuge, dry in a 60°C drying oven for 24 hours, and place the product in Calcined at 550°C for 4 hours to obtain a porous heterogeneous mesoporous material.

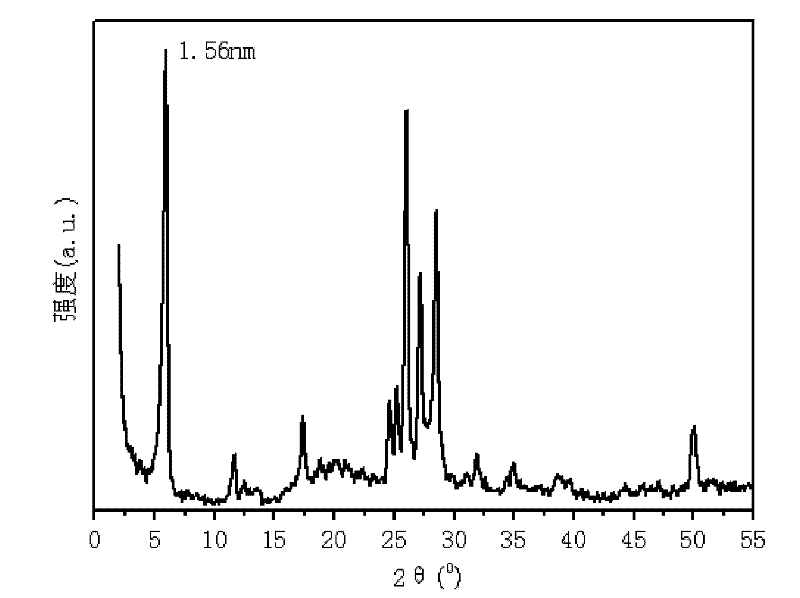

[0057] The X-ray diffraction pattern of the porous heterogeneous mesoporous material prepared in Examp...

Embodiment 2

[0060] Raw materials: the magadiite sample prepared in Comparative Example 1, tetrabutylammonium bromide, ethyl orthosilicate (Beijing Chemical Plant), n-octylamine (product of Beijing Bailingwei Technology Co., Ltd.), deionized water.

[0061] Weigh 1 g of the magadiite sample prepared in Comparative Example 1, mix it evenly with tetrabutylammonium bromide and deionized water in a molar ratio of 1:14:2364, stir at 80° C. for 16 hours, wash with water, and centrifuge at 60 The samples were obtained by drying in a drying oven at ℃ for 24 hours. Then weigh 2 g of the sample obtained after drying, mix it with n-octylamine and tetraethyl orthosilicate in a molar ratio of 1:29.3:127, stir for 5 hours, then centrifuge, and dry it in a 60°C drying oven for 24 hours. Calcined at 550°C for 5 hours to obtain a porous heterogeneous mesoporous material.

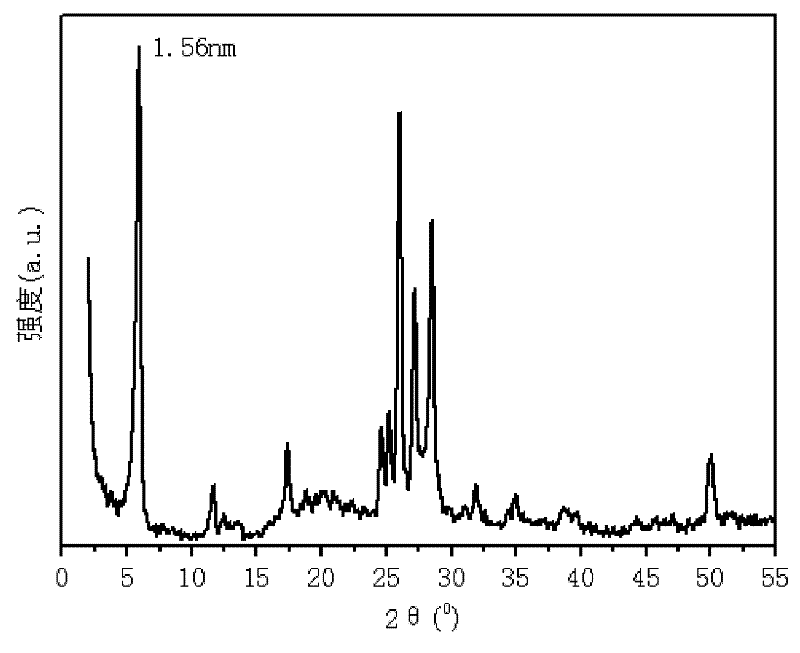

[0062] Product characterization results show that the interlayer spacing of the porous heterogeneous mesoporous material prepared in E...

Embodiment 3

[0065] Raw materials: the magadiite sample prepared in Comparative Example 1, tetraethylammonium hydroxide, ethyl orthosilicate (Beijing Chemical Plant), n-octylamine (product of Beijing Bailingwei Technology Co., Ltd.), deionized water.

[0066] Weigh 1 g of the magadiite sample prepared in Comparative Example 1, mix it evenly with tetraethylammonium hydroxide and deionized water in a molar ratio of 1:13:2068, stir at 70°C for 20 hours, wash with water and centrifuge, The samples were obtained by drying in a drying oven at ℃ for 24 hours. Weigh again 2 g of the sample obtained after drying, mix it with n-octylamine and tetraethyl orthosilicate in a molar ratio of 1:30.4:148, stir for 6 hours, then centrifuge, dry in a 60°C drying oven for 24 hours, and place the product in Calcined at 550°C for 6 hours to obtain a porous heterogeneous mesoporous material.

[0067] The sample characterization results show that the interlayer spacing of the porous heterogeneous mesoporous mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com