Nonaqueous electrolyte secondary battery and method for manufacturing same

A non-aqueous electrolyte and secondary battery technology, applied in the direction of secondary batteries, final product manufacturing, battery pack components, etc., can solve problems such as defective products, diaphragm offset, current leakage, etc., to reduce adverse conditions, suppress bias effect of displacement or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

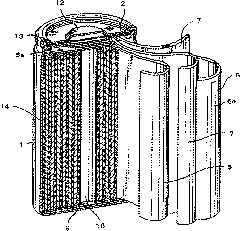

[0119] (1) Preparation of positive electrode 5

[0120] Add 100 parts by weight of lithium cobaltate as positive electrode active material, 2 parts by weight of acetylene black as conductive agent, and 3 parts by weight of polyvinylidene fluoride resin as binder in an appropriate amount of N-methyl-2-pyrrolidone, Kneading is performed to prepare a slurry-like mixture. The slurry was intermittently and continuously applied to both surfaces of a strip-shaped aluminum foil (thickness: 15 μm), followed by drying. Next, rolling was performed 2 to 3 times with a roll at a line pressure of 1000 kgf / cm (9.8 kN / cm) to adjust the thickness to 180 μm. The positive electrode 5 having a positive electrode active material layer on the surface was produced by cutting into a size of 57 mm in width and 620 mm in length. The active material density of the positive electrode active material layer was 3.6 g / mL.

[0121] The positive electrode lead terminal 5 a made of aluminum was ultrasonically...

Embodiment 2

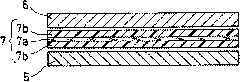

[0136] In addition to using image 3 A non-aqueous electrolyte secondary battery was produced in the same manner as in Example 1 except that the separator 7 having the three-layer structure shown was used as the separator.

[0137] Separator 7 was produced in the same manner as in Example 1, except that one of the two polyethylene porous films 7 b was replaced with a polypropylene porous film (thickness: 8.5 μm).

[0138] In the electrode group 14 of the non-aqueous electrolyte secondary battery, the separator 7 is arranged such that the polypropylene porous membrane 7 c faces the positive electrode 5 .

Embodiment 3

[0140] In addition to using figure 2 The non-aqueous electrolyte secondary battery was produced in the same manner as in Example 1, except that the intermediate layer 7 a was a separator 7 of a three-layer structure including a heat-resistant porous film of polyimide as a separator. The diaphragm 7 is produced in the following steps.

[0141] After casting an NMP solution containing calcium chloride and polyamic acid which is a precursor of polyimide at a predetermined concentration, the obtained film is stretched. The stretched film was washed with water to remove calcium chloride, thereby producing a porous film. This porous membrane was heated at 300° C. to perform dehydration imidization, thereby obtaining a heat-resistant porous membrane 7 a made of polyimide having a thickness of 3 μm. The obtained heat-resistant porous membrane 7 a was sandwiched between two polyethylene porous membranes 7 b having a thickness of 8.5 μm, and rolled with a hot roll at 80° C., thereby ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com