Variable capacitive element, variable capacitive device, and method for driving the variable capacitive element

A variable capacitance and driving voltage technology, applied in variable capacitors, capacitors that change capacitance mechanically, capacitors that change the distance between electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

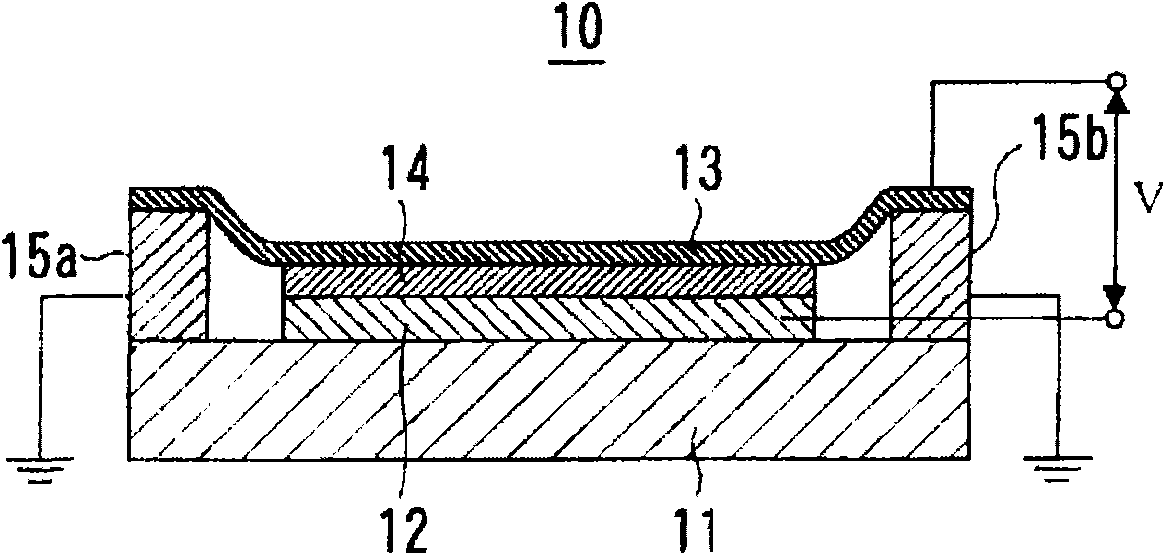

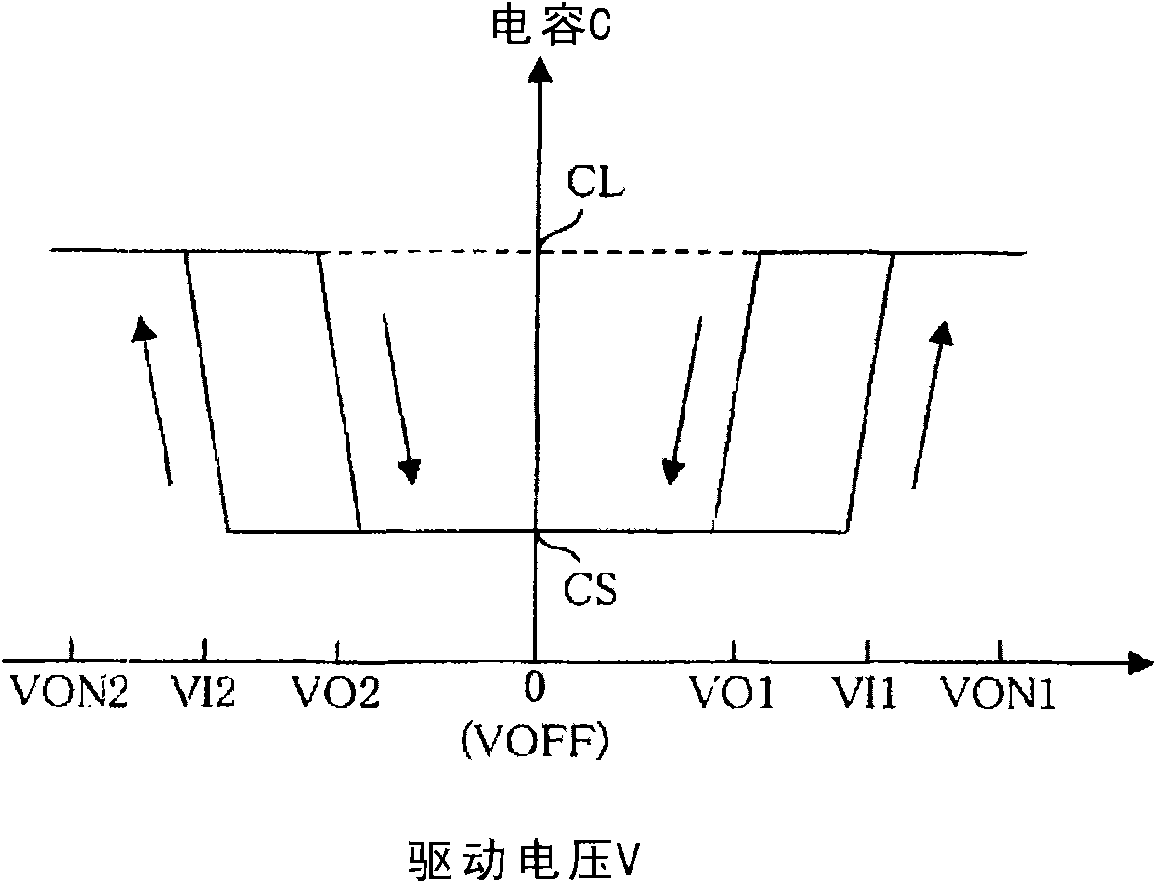

[0048] Figure 5 is a plan view showing an example of the structure of the variable capacitance device 1 according to the first embodiment; Figure 6-9 yes Figure 5 A cross-sectional view of the variable capacitance device 1 shown in . Figure 7 and 8 The same cross section is shown. Figure 7 shows a cross-section of the variable capacitive device 1 without moving the movable electrode 26, while Figure 8 A cross-section of the variable capacitance device 1 is shown with the movable electrode 26 moving.

[0049] refer to Figure 5 , the variable capacitance device 1 includes a variable capacitance element 2 , RF blocks 60 a - 60 c , a driving circuit 61 , and a driving circuit 62 . The variable capacitance element 2 includes a substrate 20 made of glass or silicon. On the substrate 20 are formed the first extraction electrode 21 , the second extraction electrode 22 , the first fixed electrodes 23 a - 23 c , the second fixed electrodes 24 a - 24 c , the movable electrode ...

no. 2 example

[0104] Figure 17 is a plan view showing the structure of the variable capacitance device 3 according to the second embodiment, Figure 18 is along Figure 17 The cross-sectional view of the variable capacitive device 3 taken by the line α1-α1.

[0105] The variable capacitive device 3 will be described below, focusing on the differences between the variable capacitive device 1 and the variable capacitive device 3 . Descriptions of the same parts as those in the variable capacitance device 1 are sometimes omitted.

[0106] refer to Figure 17 , the variable capacitance device 3 includes a variable capacitance element 4 , RF blocks 60 a - 60 c , a drive circuit 61 , and a drive circuit 62 . The variable capacitance element 4 includes a substrate 40 made of glass or silicon. On the substrate 40 are formed a fixed electrode 41 , a first extraction electrode 42 , a second extraction electrode 43 , a connection layer 44 , first movable electrodes 45 a and 45 b , second movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com