Vertical biomass hot blast heater

A hot blast stove, biomass technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large amount of smoke and dust, insufficient combustion, low thermal efficiency, etc., to improve combustion efficiency and save consumption , The effect of reducing dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

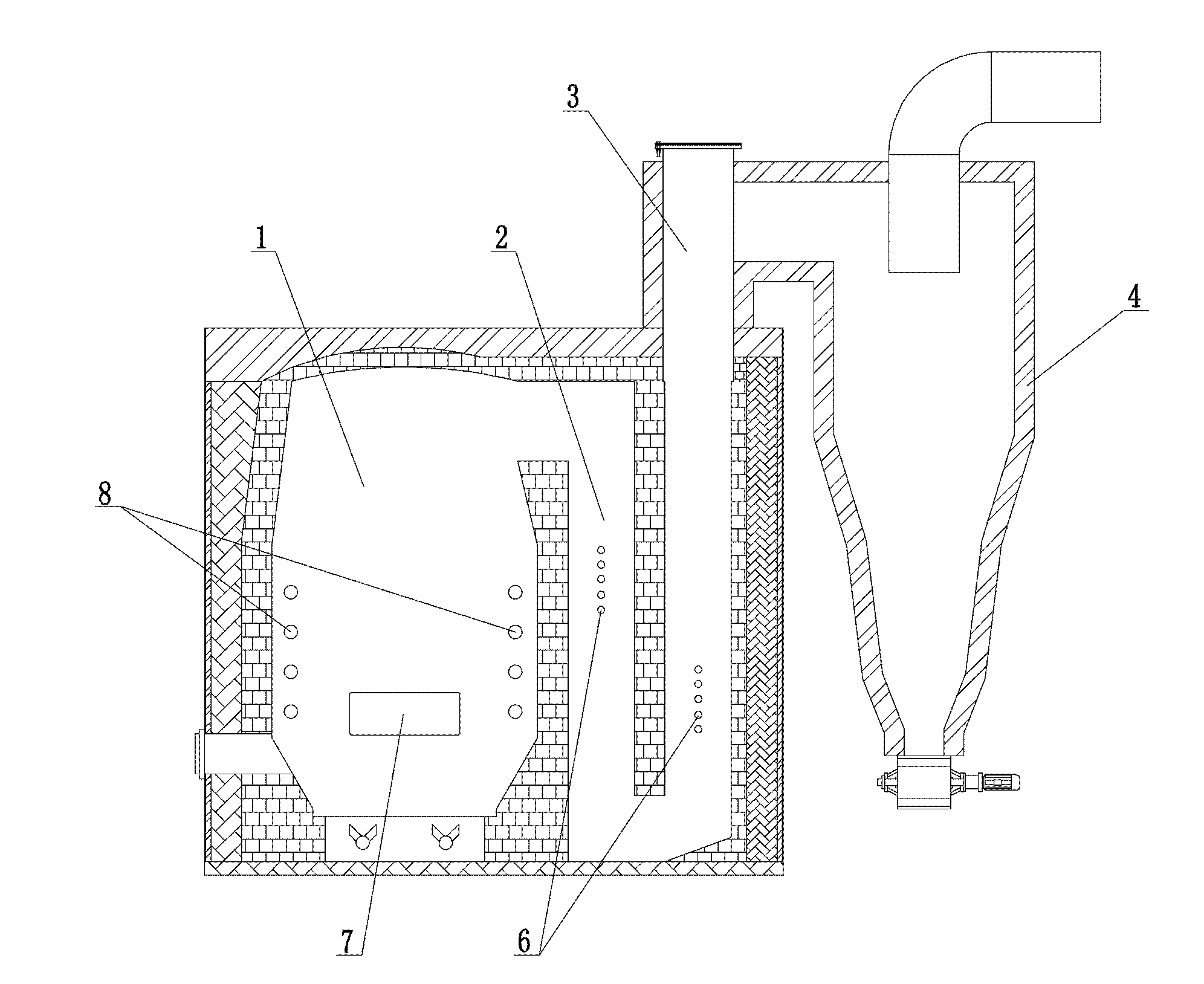

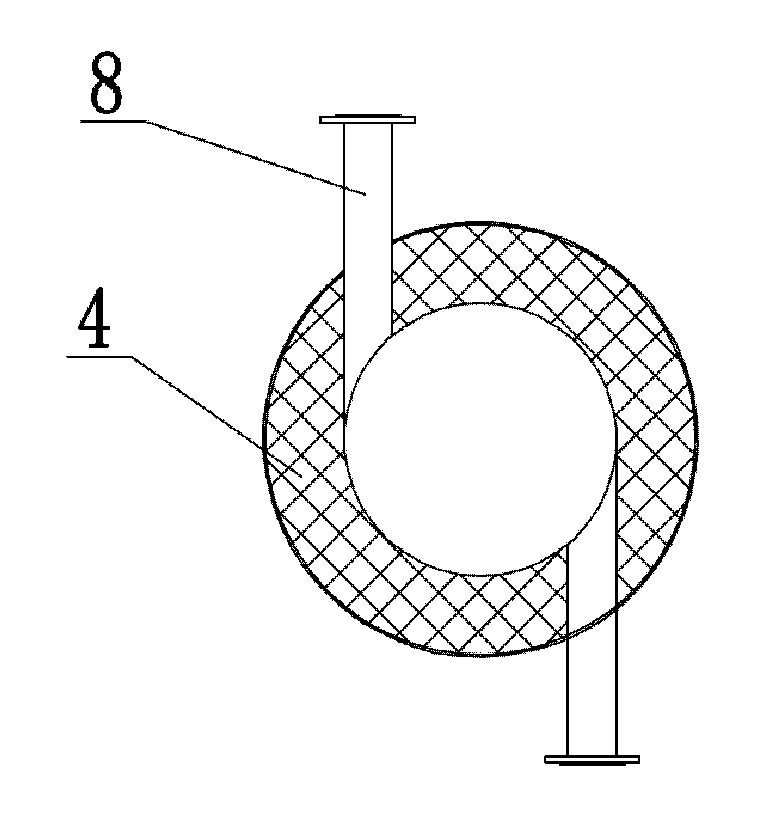

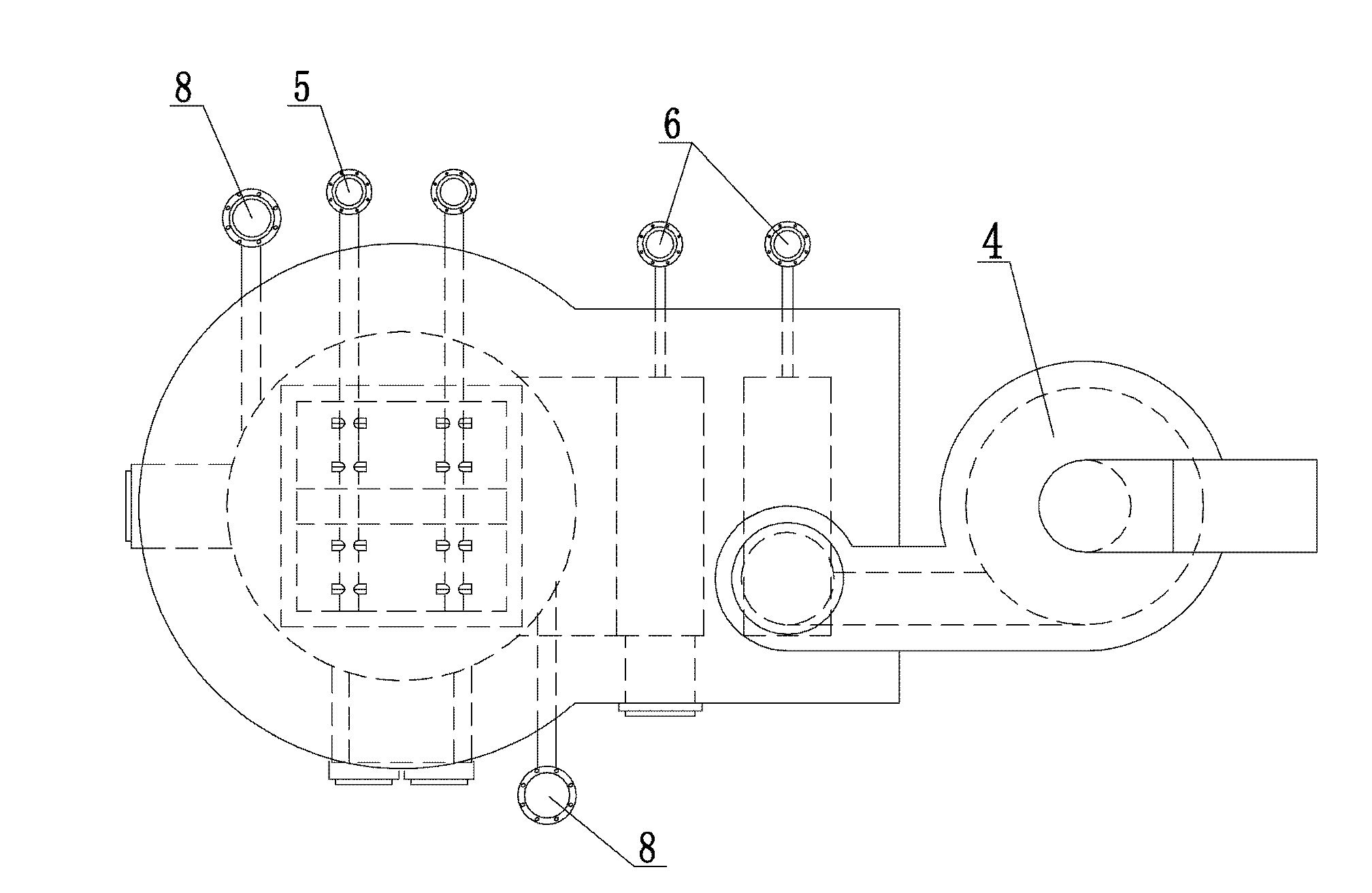

[0021] Such as figure 1 , figure 2 As shown, the hot blast stove of the present invention is improved from the original rectangular hot blast stove, and the combustion chamber of the hot blast stove is separated into three combustion chambers with different functions, so as to realize more effective segmented combustion. The hot blast stove of the present invention is made up of main combustion chamber 1, auxiliary combustion chamber 2, settling chamber 3 and cyclone dust collector 4. The inner cavity of the main combustion chamber 1 is a cylindrical structure, and the side wall of the main combustion chamber 1 is provided with some primary air holes 8, and the inwall of the primary air holes 8 is vertically tangent to the side wall of the main combustion chamber 1 ( image 3 ). The inner cavity of the secondary combustion chamber 1 and the settling chamber 3 is square (certainly also can be cylindrical), and the side walls of the secondary combustion chamber 2 and the sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com