Preparation method and application of ionic liquid functionalized Al-MCM-41 mesoporous material

A technology of al-mcm-41 and mesoporous materials, which is applied in the fields of carbon dioxide or inorganic carbonate preparation, educts, organic chemistry, etc., can solve problems such as the limitation of the application of homogeneous catalysts and the difficulty of separating homogeneous catalysts from products, etc. Achieve the effect of simple preparation process and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

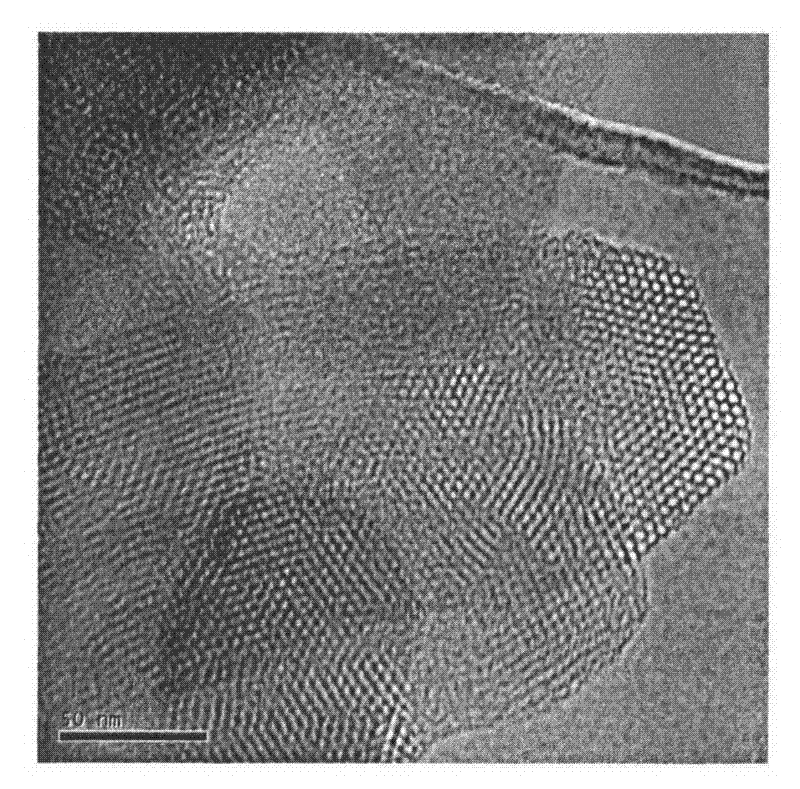

[0024] Dissolve 0.213g of aluminum nitrate and 2.4g of cetyltrimethylammonium bromide in 100mL of deionized water (Si:Al molar ratio is 80), add 3mL of ethylenediamine, stir well at room temperature, dropwise add 10mL of Ethyl silicate, after stirring vigorously at room temperature for 4 hours, placed it in a water bath at 80°C for 1 hour, moved it to a 100mL hydrothermal reaction kettle, hydrothermally crystallized at 100°C for 72h, filtered, washed with 300mL deionized water, and placed in Dry at 100°C for 8h, and finally raise the temperature to 550°C at a rate of 1°C / min in a muffle furnace, and bake at 550°C for 6h to obtain a skeleton-doped aluminum-doped mesoporous material Al-MCM-41 (80).

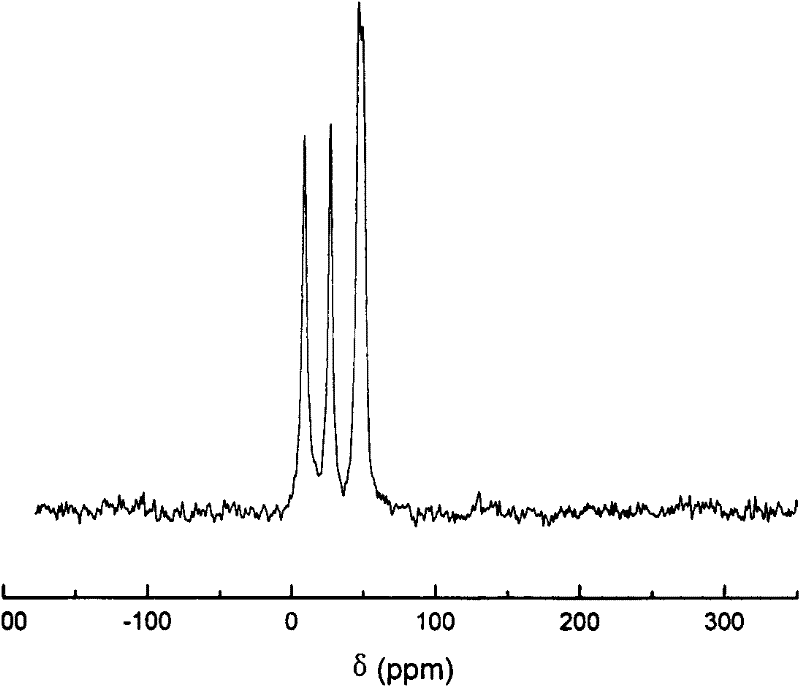

[0025] Take 5.0g of the prepared Al-MCM-41(80), add 100mL of toluene, add 5.0mL of 3-chloropropyltrimethoxysilane, add 0.5mL of triethylamine, and reflux at a temperature of 112°C for 48h. After the end, cool to room temperature, carry out vacuum suction filtration, then successivel...

Embodiment 2

[0028] The preparation method is the same as in Example 1, only changing the aluminum salt precursor sodium metaaluminate (NaAlO 2 ), that is, take 0.122g sodium metaaluminate (NaAlO 2 ) and 2.4g of cetyltrimethylammonium bromide were dissolved in 100mL of deionized water (Si:Al molar ratio was 30), 4mL of ethylenediamine was added, fully stirred at room temperature, and 10mL of ethyl orthosilicate was added dropwise , after stirring vigorously at room temperature for 4 hours, put it in a water bath at 80°C for 1 hour, move it to a 100mL hydrothermal reaction kettle, conduct hydrothermal crystallization at 100°C for 72h, filter, wash with 300mL deionized water, and dry at 100°C After 8 hours, the temperature was raised to 550°C at a speed of 1°C / min in a muffle furnace, and then fired at 550°C for 6 hours to obtain a skeleton-doped aluminum mesoporous material Al-MCM-41 (30).

[0029] Take 5.0g of the prepared Al-MCM-41(30), add 100mL of toluene, add 5.0mL of 3-chloropropyltr...

Embodiment 3

[0032] The reaction of propylene oxide and carbon dioxide to generate propylene carbonate was carried out in a 50mL stainless steel autoclave and heated by electromagnetic stirring. Add 5g of propylene oxide into the reaction kettle, add 0.4g of the prepared ionic liquid functionalized Al-MCM-41 mesoporous material catalyst, then pass in carbon dioxide gas to evacuate, close the outlet valve, and close the inlet after the pressure shows 3MPa valve. Stir and heat up to a reaction temperature of 130° C., and react at a constant temperature for 6 hours. After the reaction, the reactor was placed in an ice-water bath for 3 hours, and then unreacted carbon dioxide gas was released, and the solid catalyst was separated by centrifugation.

[0033] The product is analyzed by gas chromatography: hydrogen flame ionization detector, nitrogen as carrier gas, gasification chamber temperature 260 °C, detector temperature 260 °C, sample volume 0.2 μL, analysis conditions are initial column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com