Low-cost high-strength high-toughness shock-proof refractory steel and preparation technique thereof

A high-strength, high-toughness, preparation process technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of high alloy cost and process cost, complex production methods, etc., and achieve low alloy cost, less content, and process low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

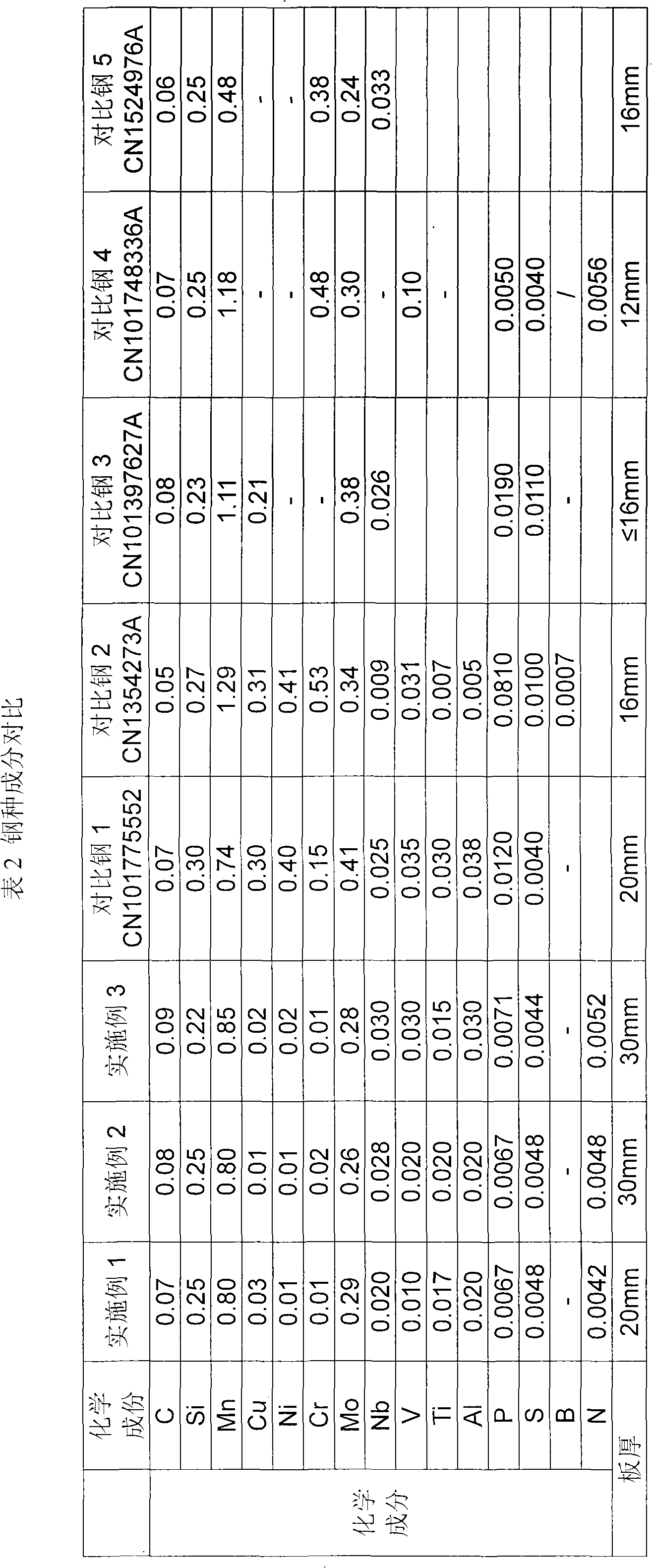

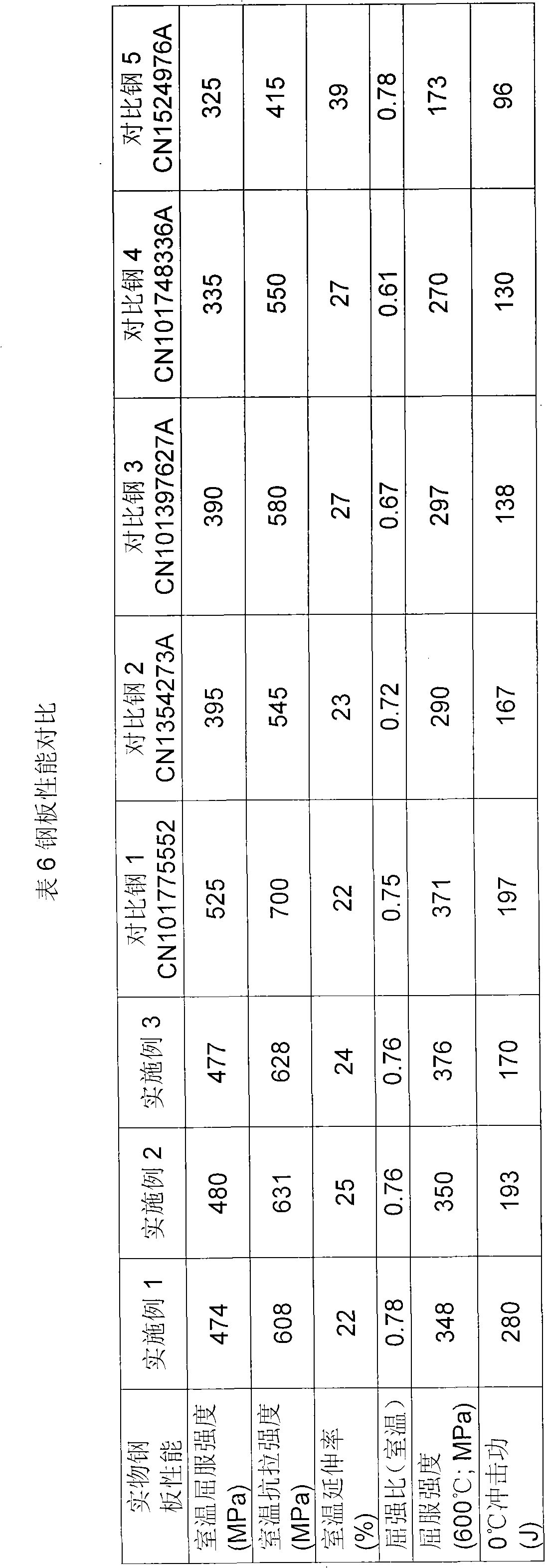

[0023] Embodiment 1: The chemical composition of the steel grade of this embodiment is shown in Table 2, and the balance is Fe and unavoidable inclusions. The preparation process is as follows: according to the chemical composition requirements of the steel grade of this embodiment, the molten steel is obtained by smelting in a 150kg vacuum induction furnace; The molten steel is poured into steel ingots, then heated to 1180-1230°C and held for 2-3 hours, and then out of the furnace for rough rolling at 1100°C with a reduction rate of 0.6; after the rough rolling, the 60mm thick rolled plate is kept warm on the roller table; finish rolling The starting temperature is 880°C, the final rolling temperature is 860°C, and rolled to a thickness of 20mm; after rolling, the rolled plate is cooled to 500°C at a rate of 9°C / s and then air-cooled to room temperature to produce the target steel plate. The physical mechanical properties of the rolled plate are shown in Table 3.

Embodiment 2

[0024] Embodiment 2: The chemical composition of the steel grade in this embodiment is shown in Table 2, and the balance is Fe and unavoidable inclusions. The preparation process is as follows: according to the chemical composition requirements of the steel grade in this embodiment, vacuum induction smelting is used to obtain molten steel; the molten steel is poured After being heated and kept warm, it is rolled out of the furnace at 1030°C, and the thickness of the steel plate is rolled from 150mm to 75mm; after being heated, it is rolled at 900°C, and the thickness of the steel plate is rolled from 75mm to 30mm; after rolling, the plate is rolled at a rate of 6°C / s Speed cooling to 550°C and air cooling to room temperature to produce the target steel plate. The physical mechanical properties of the rolled plate are shown in Table 3.

Embodiment 3

[0025] Example 3: The chemical composition of the steel in this example is shown in Table 2, and the balance is Fe and unavoidable inclusions. The preparation process is basically similar to that of Example 1-2, but after the billet is heated and kept warm, it starts at 1060°C Rolling, the thickness of the steel ingot is rolled from 170mm to 80mm; after being heated, it is rolled at 860°C, and the thickness of the rolled plate is rolled from 80mm to 30mm; after rolling, it is cooled to 600°C at a speed of 15°C / s and then air-cooled to room temperature to obtain the target steel plate. The physical mechanical properties of the rolled plate are shown in Table 3.

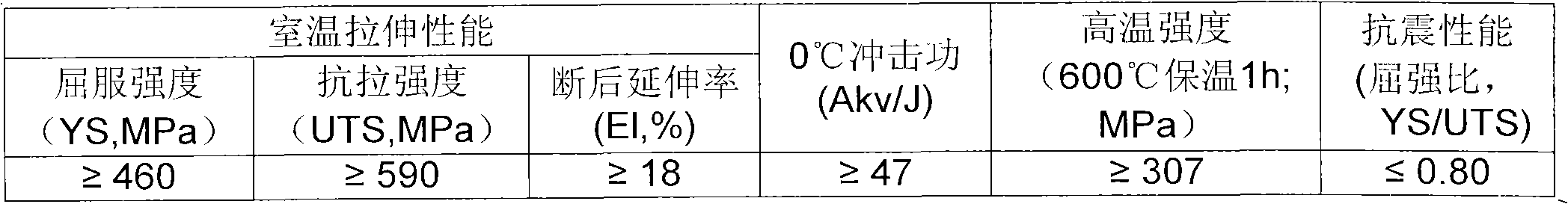

[0026] It can be seen that, by reducing the addition of alloy elements, the present invention can still obtain a comprehensive combination of room temperature yield strength ≥ 460MPa, 600°C yield strength ≥ 307MPa, yield ratio ≤ 0.8, and 0°C impact energy ≥ 47J by reducing the addition of alloying elements. Good fire-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com