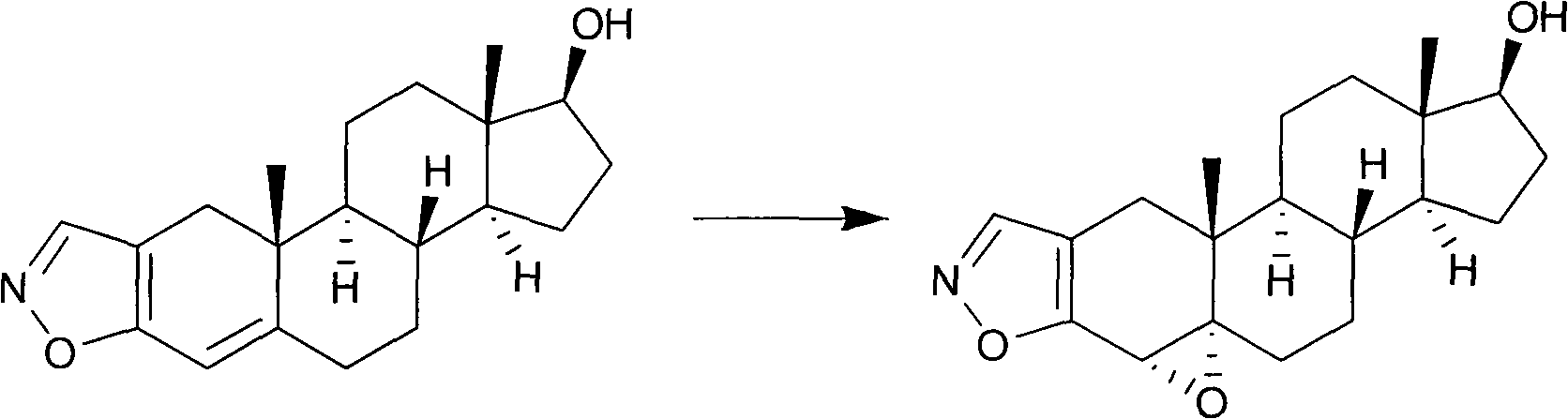

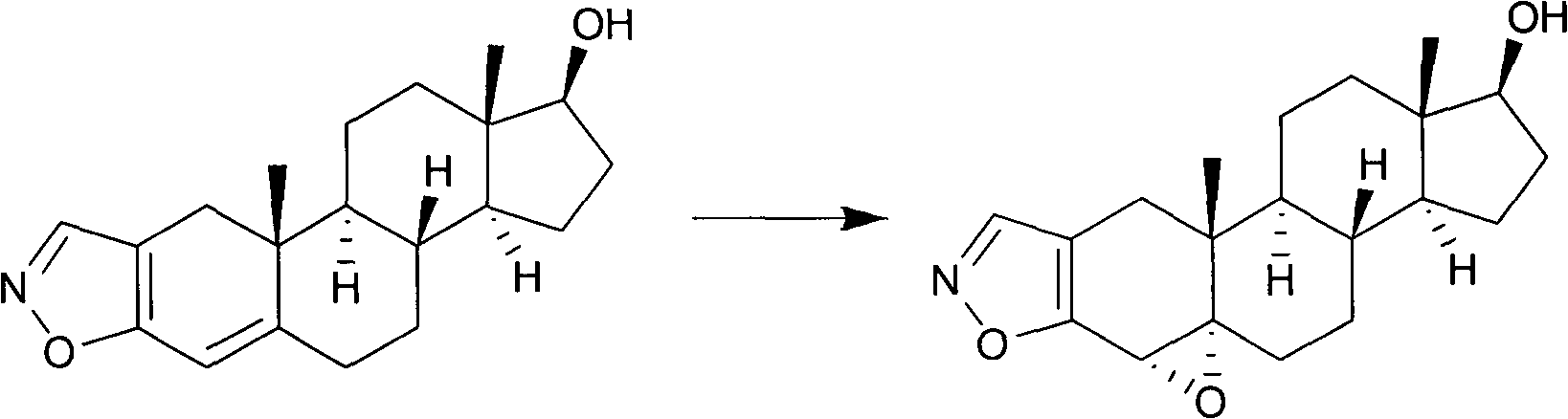

Preparation method of moguisteine intermediate 17 beta-hydroxyl-4 alpha, 5 alpha-epoxy androstane (2,3-d) isoxazole

A technology of epoxyandrostane and 3-d, which is applied in the field of preparation of Mojostein intermediate 17β-hydroxy-4α,5α-epoxyandrostano(2,3-d)isoxazole, can Solve problems such as the reduction of epoxide selectivity, and achieve the effect of high selectivity, high yield and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of 17β-hydroxyl-4α, 5α-epoxyandrostano[2,3-d]isoxazole

[0021] Add 3.13g (0.01mol) of 17β-hydroxy-4-androstano[2,3-d]isoxazole into a 100ml three-necked flask, then add 50ml of benzene, stir magnetically, and control the temperature at 0°C. Under temperature, add 22.6mg (0.1mmol) diazepam Schiff base (E)-4--(pyridine-2-amino) benzoic acid, 25mg (0.1mmol) rhenium trioxide and 2.27g (0.02mol) 30%H 2 o 2 Aqueous solution, after stirring for 6 hours, stop the reaction, add a little sodium thiosulfate to remove excess H 2 o 2 , the catalyst was removed by filtration, and the residue was recrystallized with acetone to obtain 2.75 g of 17β-hydroxy-4α,5α-epoxyandrostano[2,3-d]isoxazole after evaporating the solvent, with a yield of 85.0%.

[0022] Melting point 204~206℃;

[0023] 13 C NMR (CDCl 3 )6: 11.1 (s, _C-18), 16.8 (s, C-19), 20.8 (s, C-11), 23.5 (s, C-15), 27.9 (s, C-7), 30.0 ( s, C-6), 30.2 (s, C-16), 30.4 (s, C-10), 35.9 (s, C-1), 36.5 ...

Embodiment 2

[0024] Example 2: Preparation of 17β-hydroxyl-4α, 5α-epoxyandrostano[2,3-d]isoxazole

[0025] Add 3.13g (0.01mol) of 17β-hydroxy-4-androstano[2,3-d]isoxazole into a 100ml three-neck flask, then add 50ml of dichloromethane, stir magnetically, and control the temperature at 10°C. At this temperature, add 22.6mg (0.1mmol) diazepam Schiff base (E)-4--(pyridine-2-amino)benzoic acid, 25mg (0.1mmol) methyl rhenium trioxide and 2.27g (0.02 mol)30%H 2 o 2 Aqueous solution, after stirring for 5 hours, stop the reaction, add a little sodium thiosulfate to remove excess H 2 o 2 , the catalyst was removed by filtration, and the residue was recrystallized with acetone to obtain 2.03 g of 17β-hydroxyl-4α,5α-epoxyandrostano[2,3-d]isoxazole after evaporating the solvent, with a yield of 62.8%.

Embodiment 3

[0026] Example 3: Example 2: Preparation of 17β-hydroxyl-4α, 5α-epoxyandrostano[2,3-d]isoxazole

[0027] Add 3.13g (0.01mol) of 17β-hydroxy-4-androstano[2,3-d]isoxazole into a 100ml three-necked flask, then add 50ml of toluene, stir magnetically, and control the temperature at 0°C. Under temperature, add 45.2mg (0.2mmol) diazepam Schiff base (E)-4--(pyridine-2-amino) benzoic acid, 50mg (0.2mmol) methyl rhenium trioxide and 2.27g (0.02mol) respectively 30%H 2 o 2 Aqueous solution, after stirring for 6 hours, stop the reaction, add a little sodium thiosulfate to remove excess H 2 o 2 , the catalyst was removed by filtration, and the residue was recrystallized with acetone to obtain 2.27g of 17β-hydroxyl-4α,5α-epoxyandrostano[2,3-d]isoxazole after evaporating the solvent, with a yield of 70.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com